Chain Conveyor for Clinker, Cement & Bulk Materials

(Konveyor Rantai untuk Klinker, Semen & Material Curah)

Stable & Dust-proof Conveying for Bulk Materials

Overview

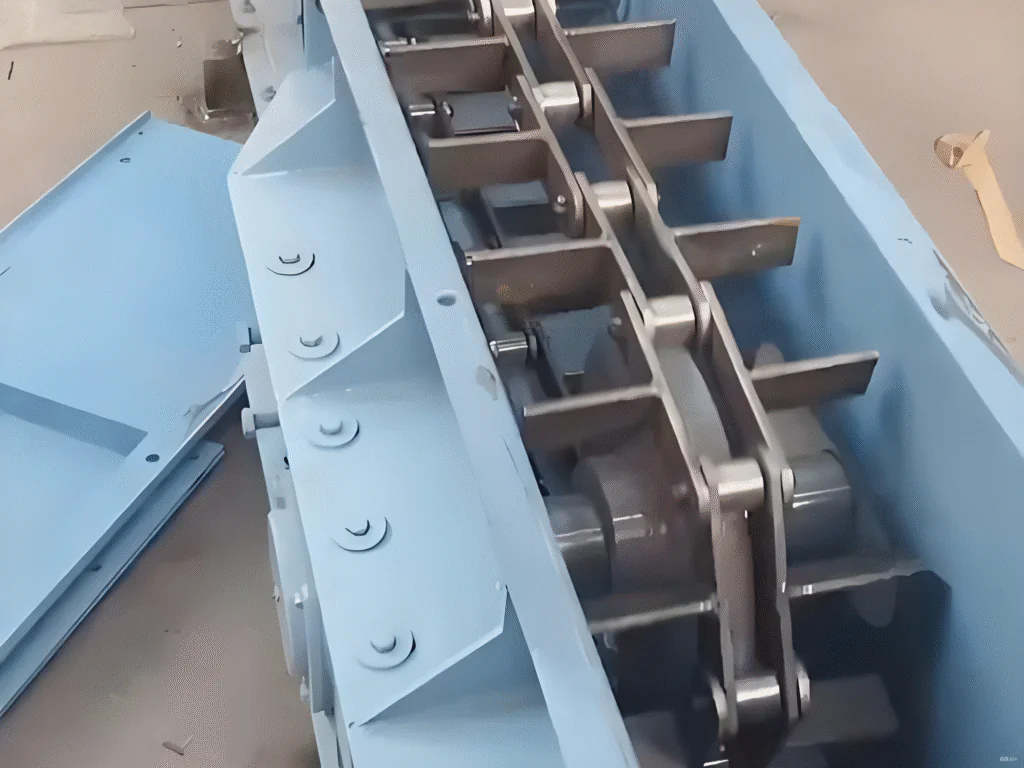

Chain conveyor is a reliable and heavy-duty conveying solution for horizontal or inclined transport of bulk materials. With forged chain, wear-resistant liners, and enclosed dust-proof housing, it ensures long service life with low maintenance.

It is widely used for clinker, cement, fly ash, slag, and abrasive bulk materials in cement plants and industrial handling systems.

For related equipment, see our Bucket Elevator for Bulk Materials and Air Slide Conveyor System.

Working Principle

The motor drives the forged chain and scraper flights along the trough. Bulk materials are pushed forward and discharged through the outlet.

The enclosed housing reduces dust escape and ensures stable, continuous conveying — ideal for clinker and cement chain conveyor applications.

Learn more about bulk material conveying principles from Wikipedia – Conveyor System.

Technical Specifications

| Model | Width (mm) | Capacity (t/h) | Speed (m/s) | Material Temp | Motor (kW) |

|---|---|---|---|---|---|

| MC200 | 200 | 10–40 | 0.16–0.32 | ≤ 200°C | 2.2–7.5 |

| MC300 | 300 | 40–80 | 0.16–0.32 | ≤ 200°C | 4–11 |

| MC400 | 400 | 80–150 | 0.16–0.32 | ≤ 200°C | 7.5–15 |

| MC500 | 500 | 150–250 | 0.16–0.32 | ≤ 200°C | 11–22 |

*Technical specifications are for reference only.

Features

✅ Heavy-duty forged chain

✅ Wear-resistant steel trough

✅ Sealed structure to prevent dust leakage

✅ Stable and continuous conveying

✅ Lower maintenance cost

✅ Suitable for high-temperature clinker

Advantages

✅ Good sealing, no environmental pollution

✅ Long lifetime with wear-resistant liners

✅ Suitable for high-temperature material

✅ Large capacity and stable operation

✅ Easy installation and maintenance

FAQS About Chain Conveyor

What materials are suitable for a chain conveyor?

A chain conveyor is suitable for handling bulk materials such as clinker, cement, fly ash, slag, limestone, and other abrasive or high-temperature materials. It is commonly used in cement plants and industrial bulk material handling systems where durability and dust control are required.

What is the difference between a chain conveyor and a belt conveyor?

A chain conveyor uses forged chains and scrapers to move materials through a steel trough, making it more suitable for high-temperature and abrasive materials. A belt conveyor is better for long-distance transport of non-abrasive bulk materials with lower operating temperatures.

Can a chain conveying system operate at high temperatures?

Yes. Chain conveyors are designed to handle high-temperature materials such as clinker, typically up to 200°C or higher depending on design and liner configuration, making them ideal for cement plant applications.

Is the chain conveying system equipment fully enclosed?

Yes. Most heavy-duty conveying equipment feature a fully enclosed, dust-proof housing that prevents material leakage and reduces environmental pollution during conveying operations.

Need a Reliable Chain Conveyor for Your Bulk Material Handling System?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects