Bulk Material Conveying System for Cement, Fly Ash & Mining

(Sistem Konveyor Material Curah untuk Semen, Abu Terbang & Pertambangan)

High-performance conveying solutions for cement, fly ash, clinker and industrial bulk materials.

Overview

LVRUI provides complete bulk material conveying systems for powders and granular materials used in cement plants, fly ash handling, mining, metallurgy, chemical processing, and grain storage.

Our conveying solutions integrate feeding devices, conveyors, flow control equipment, dust collection systems, and downstream loading units to ensure stable material flow, low energy consumption, and minimal dust emission. Each system is engineered according to material characteristics, plant layout, and operating requirements.

Typical Bulk Material Conveying System Configuration

A typical bulk material conveying system consists of material storage units, feeding devices, conveying equipment, flow control components, and downstream loading or packing systems. Depending on material characteristics and plant layout, air slide conveyors, belt conveyors, screw conveyors, or chain conveyors can be selected to form an efficient and reliable conveying line.

Depending on material properties and conveying distance, air slide conveyors, belt conveyors, screw conveyors, chain conveyors, or bucket elevators can be selected and combined to form an efficient and reliable bulk material conveying system.

Suitable Materials & Applications

LVRUI bulk material conveying systems are designed for cement plants, fly ash terminals, lime processing units, mining, grain storage, and industrial powder handling.

✅ Cement, clinker, lime, fly ash, gypsum

✅ Sand, aggregate, mineral powder, pellets

✅ Chemical powders and non-sticky granules

✅ Applications: mills, silos, packing lines, loading/unloading stations

Performance Range

✅ Capacity: 5 – 1000 t/h

✅ Particle size: powder to ≤ 80 mm

✅ Temperature: ambient to 250 °C

✅ Single-machine distance: 3 – 200 m

Our conveying solutions ensure stable transport of powders and granules with high sealing performance, low wear, and flexible layout options.

Why Choose LVRUI Conveying Systems

LVRUI provides complete bulk handling solutions including equipment design, manufacturing, installation, and after-sales support.

✅ 24/7 reliable operation with wear-resistant design

✅ High sealing structure to reduce dust and spillage

✅ Modular layout for easy installation and maintenance

✅ Suits cement, mining, building materials, chemicals & grain

✅ One-stop solution: design, manufacturing, commissioning & after-sales

What We Deliver

✅ System engineering (layout, selection, drawings)

✅ Equipment supply (standard & customized)

✅ On-site installation guidance and commissioning

✅ Spare parts package and long-term maintenance plan

✅ Remote technical support and fast response

Our engineering team supports OEM/ODM customization and turnkey bulk material conveying projects worldwide.

Product Types

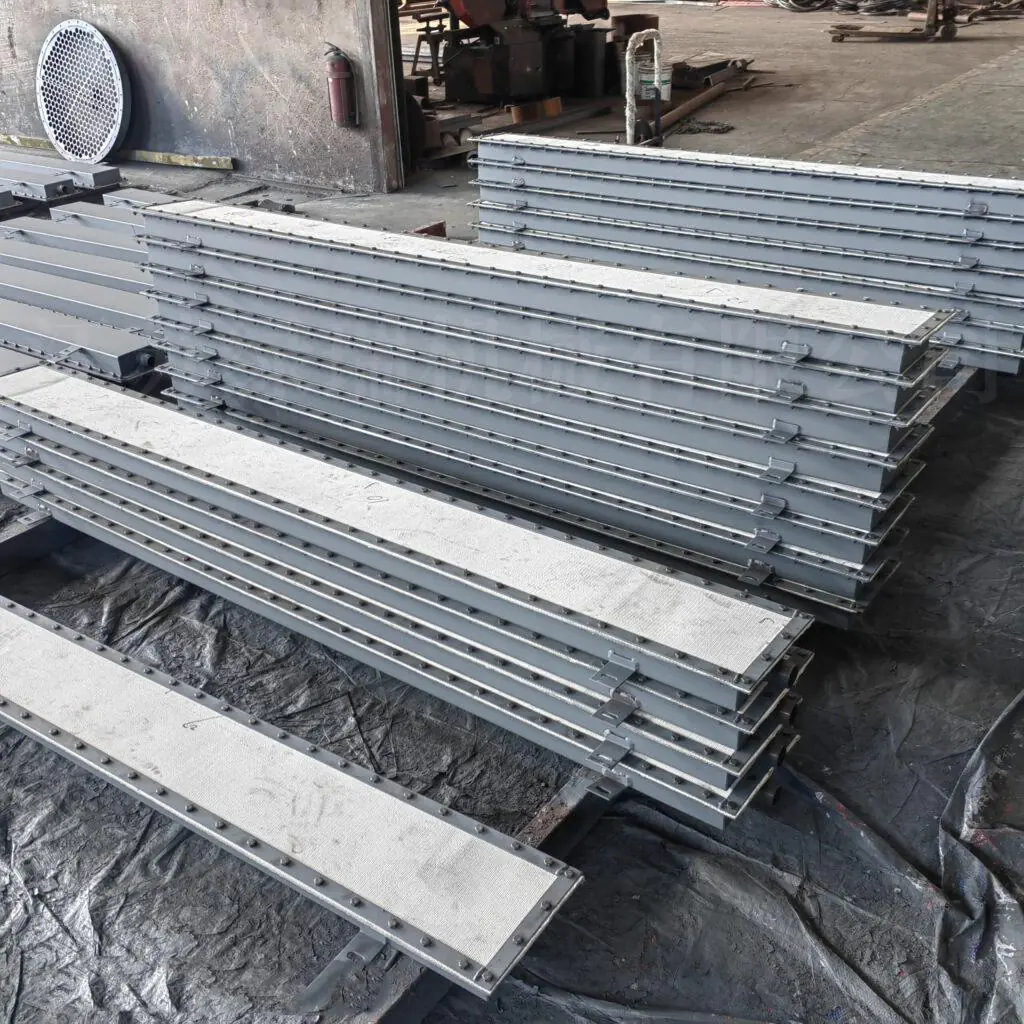

Air slide conveyors are widely used in cement plants and fly ash handling systems for energy-efficient and dust-free powder conveying.

Aeration pads are commonly used in bulk material handling systems to improve material flow by fluidizing fine powders inside silos, hoppers, and air slide conveyors.

Screw conveyors are widely used for controlled feeding and short-distance conveying of bulk materials such as cement, fly ash, and granules.

Belt conveyors are commonly applied in continuous bulk material conveying systems for long-distance transport of materials such as clinker, limestone, coal, and aggregates.

Chain conveyors are suitable for heavy-duty bulk material conveying applications requiring stable, enclosed, and wear-resistant transport, especially for hot or abrasive materials.

Bucket elevators are widely used for vertical conveying of bulk materials such as cement, fly ash, grain, and mineral powders in industrial plants.

We support OEM/ODM, on-site engineering guidance, and project customization. If you need technical support or a quotation, please contact us — our team will provide the most suitable conveying solution for your project.

Bulk material conveying systems used in industrial plants should comply with recognized material handling safety and design standards, such as those published by CEMA.

LVRUI specializes in turnkey bulk material conveying projects for cement plants, mining companies, chemical plants, grain terminals, and fly ash handling systems. Our solutions include air slide conveyors, which are commonly used for low-energy and dust-free powder conveying, as well as screw conveyors, belt conveyors, bucket elevators, chain conveyors, and customized bulk material handling systems.

FAQs About Bulk Material Conveying System

What is a bulk material conveying system?

A bulk material conveying system is an integrated solution used to transport powders and granular materials such as cement, fly ash, clinker, sand, and minerals within industrial plants. It typically consists of feeders, conveyors, flow control devices, and dust control equipment.

Which types of conveyors are commonly used in bulk material conveying systems?

Common conveyor types include air slide conveyors for fine powders, belt conveyors for long-distance transport, screw conveyors for controlled feeding, chain conveyors for heavy-duty materials, and bucket elevators for vertical conveying applications.

How do I choose the right conveying system for my material?

System selection depends on material characteristics (particle size, bulk density, abrasiveness), conveying distance, capacity requirements, plant layout, and environmental conditions. Engineering evaluation is recommended to ensure stable operation and low maintenance.

Are bulk material conveying systems suitable for cement and fly ash handling?

Yes. Bulk material conveying systems are widely used in cement plants and fly ash handling systems, providing efficient, dust-controlled, and continuous transport for powder materials across storage, processing, and loading stages.

Can a bulk material conveying system be customized for my plant layout?

Absolutely. Bulk material conveying systems can be fully customized, including equipment selection, layout design, automation level, and dust control solutions, to match specific plant requirements and operating conditions.

Ready to Get a Reliable Bulk Material Conveying System Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects