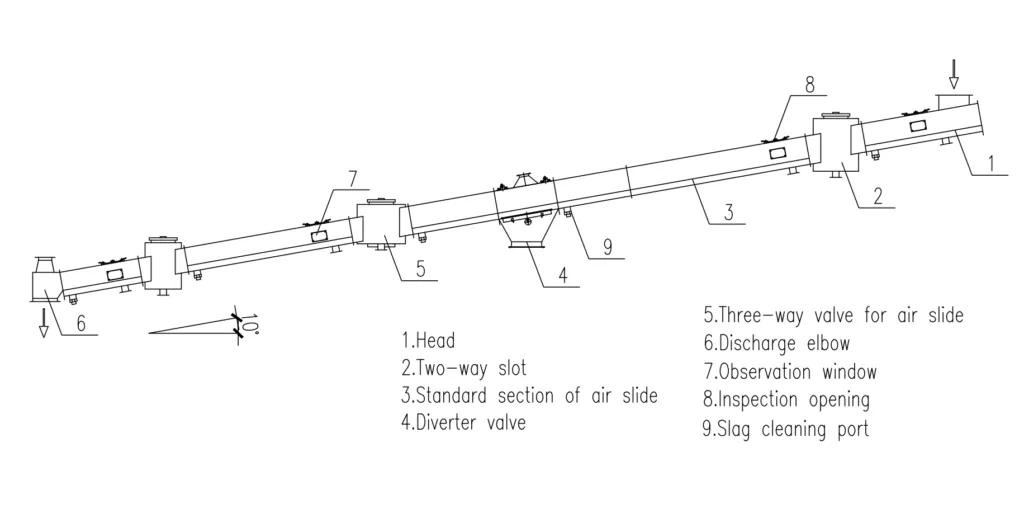

Air Gravity Conveyor System for Dry Bulk Powders

(Konveyor Air Slide – Sistem Konveyor Gravitasi Udara)

Efficient air slide conveyor for cement, fly ash, and other fine bulk powder materials

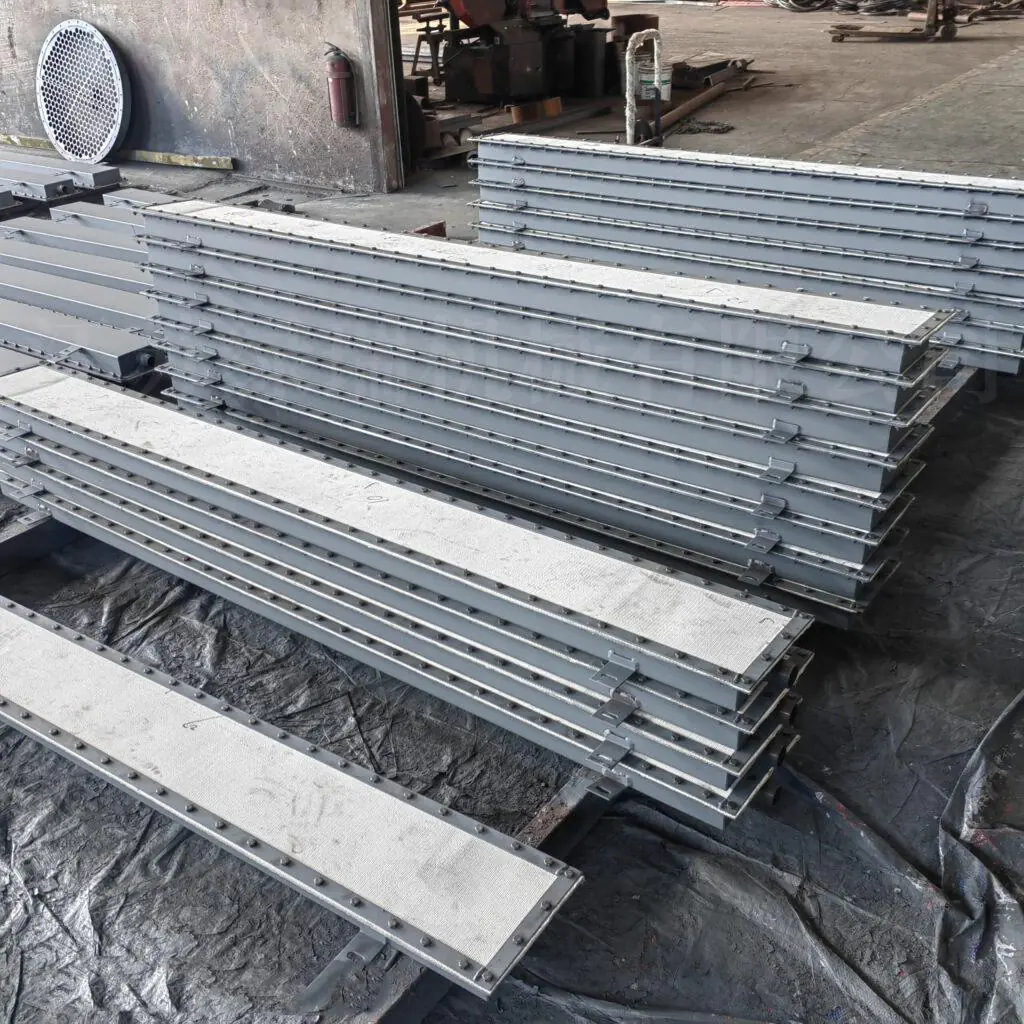

An air slide conveyor is a gravity-based bulk powder conveying system that uses low-pressure air to fluidize dry materials such as cement, fly ash, and lime powder, enabling smooth, dust-free, and energy-efficient material transport without mechanical moving parts.

Overview

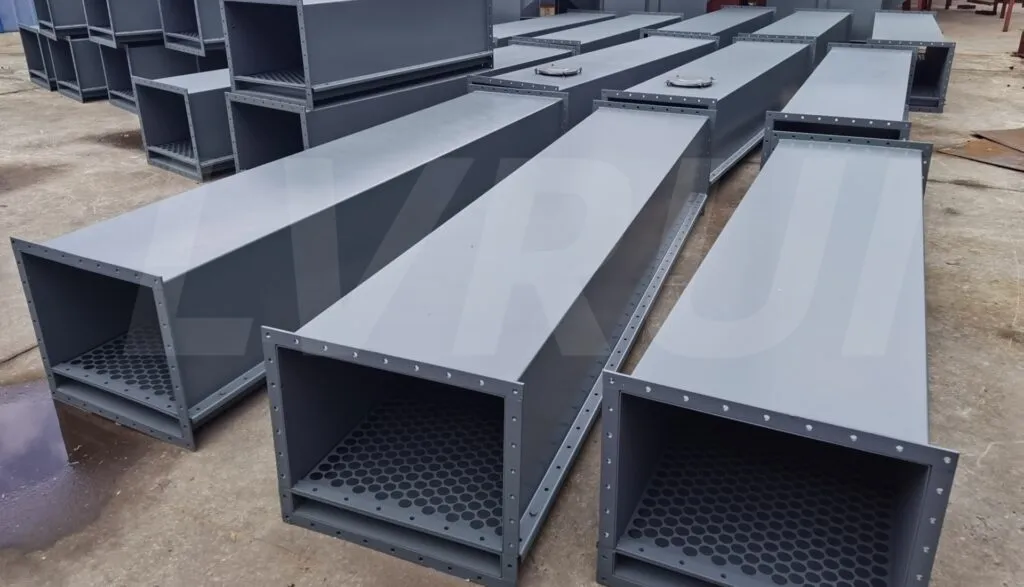

The air slide conveyor is a gravity-based powder conveying system that uses low-pressure air to fluidize dry bulk materials. It is commonly installed between silos, hoppers, packing machines, and bulk loading stations, offering energy-efficient and dust-free material transport without moving mechanical parts.As a gravity powder conveying system, air slide conveyors are widely used in cement plants, fly ash terminals, and bulk loading systems where low energy consumption and dust-free operation are required.

Air slide conveyor system is widely used between silos, packing machines, bulk loading stations, and kiln feeding systems for powder materials such as cement, fly ash, and lime. With no moving parts and fully sealed construction, the system ensures dust-free conveying, low power consumption, and minimal maintenance.

For dust-free bulk loading solutions, see our Cement Bulk Loader .

Air slide systems meet global dust emission guidelines, including compliance with U.S. EPA standards for industrial air quality and dust control.

Working Principle

Air gravity conveyor operate based on a simple but reliable principle:

✅ Compressed air enters the chamber under the porous fabric

✅ Powder becomes fluidized and flows like liquid

✅ Material is transported gently along the slope

✅ No friction, low noise, and minimal wear

This air fluidization conveying principle ensures smooth, low-energy, and maintenance-free transport of dry bulk powders.

This fluidization process is widely used in cement, minerals, and chemical industries due to its stable performance and very low mechanical wear.Compared with pneumatic conveying systems, air slide conveyors rely on low-pressure air and gravity, making them more energy-efficient for short to medium-distance powder conveying.

Features

✅ Simple structure, no rotating parts

✅ Low maintenance and long service life

✅ Completely sealed and dust-free operation

✅ Supports multiple outlets and diverters

✅ Suitable for high-temperature and abrasive powders

✅ Smooth and continuous material flow

LVRUI air slide conveying system are compatible with multiple outlets, diverters, rotary feeders, and flow control gates, allowing efficient integration into existing powder conveying and bulk loading systems.

Air slide conveyors are especially suitable for continuous powder flow in cement plants, fly ash handling systems, and bulk material transfer lines.

Technical Specifications

Below are the conveying capacities of LVRUI Air Slide Conveyor under different slide widths and inclination angles, suitable for cement, fly ash, lime powder, and other dry bulk materials.

| Slide Width (mm) | XZ200\AS200 | XZ250\AS250 | XZ315\AS315 | XZ400\AS400 | XZ500\AS500 | XZ630\AS630 | XZ800\AS800 |

|---|---|---|---|---|---|---|---|

| Capacity at α = 4° (t/h) – Cement | 22 | 40 | 70 | 130 | 220 | 320 | 400 |

| Capacity at α = 4° (t/h) – Raw Material | 16 | 30 | 55 | 100 | 165 | 245 | 310 |

| Capacity at α = 6° (t/h) – Cement | 40 | 65 | 120 | 250 | 400 | 610 | 765 |

| Capacity at α = 6° (t/h) – Raw Material | 30 | 55 | 90 | 185 | 300 | 455 | 565 |

| Capacity at α = 8° (t/h) – Cement | 50 | 80 | 140 | 300 | 470 | 720 | 900 |

| Capacity at α = 8° (t/h) – Raw Material | 35 | 65 | 110 | 225 | 355 | 540 | 670 |

| Capacity at α = 10° (t/h) – Cement | 60 | 100 | 170 | 380 | 570 | 900 | 1080 |

| Capacity at α = 10° (t/h) – Raw Material | 45 | 80 | 140 | 285 | 425 | 670 | 800 |

| Capacity at α = 12° (t/h) – Cement | 70 | 120 | 205 | 455 | 685 | 1080 | 1295 |

| Capacity at α = 12° (t/h) – Raw Material | 50 | 95 | 165 | 340 | 510 | 805 | 960 |

Technical data can be customized depending on material density, temperature, and required conveying distance. Contact LVRUI for engineering support.

Air slide conveyors are widely used in cement plants, fly ash terminals, silo feeding and discharge systems, packing lines, and bulk powder handling facilities. They provide stable and continuous powder conveying with minimal energy consumption and mechanical wear.

Applications

Air Slide Conveyors are widely applied in:

✅ Cement plants and cement grinding systems

✅ Fly ash terminals and fly ash handling systems

✅ Silo feeding and discharge lines

✅ Packing and bulk loading systems

✅ Pneumatic and hybrid bulk powder conveying systems

Air slide conveyors are essential in cement grinding stations, fly ash terminals, bulk powder depots, kiln feeding lines, and pneumatic conveying systems. They ensure stable and continuous powder flow without mechanical wear.

For dust-free bulk loading operations, the Dust-Free Loading Spout is commonly integrated with air slide conveyors to minimize material loss and environmental pollution.

Typical applications include air slide conveyors for cement plant silo discharge, fly ash handling systems, bulk powder transfer lines, and integration with bulk loading spouts.

System Integration in Cement and Fly Ash Handling Lines

Air slide conveyors are typically integrated with cement silos, flow control gates, aeration systems, and dust-free bulk loading equipment to form a complete powder handling and bulk loading system with minimal maintenance and energy consumption.

FAQs About Air Slide Conveyor

What materials are suitable for an air slide conveyor?

Air slide conveyors are suitable for dry, fine, and free-flowing bulk powders such as cement, fly ash, lime powder, and similar materials that can be fluidized by low-pressure air. They are not suitable for wet, sticky, or granular materials.

What is the difference between an air slide conveyor and a pneumatic conveyor?

An air slide conveyor uses gravity and air fluidization to convey powder with low-pressure air, while a pneumatic conveyor uses high-pressure air to transport materials through pipelines. Air slide conveyors are more energy-efficient and wear-free for short to medium conveying distances.

Does an air slide conveyor require moving mechanical parts?

No. Air slide conveyors have no rotating or moving conveying parts, resulting in low maintenance and long service life.

Can air slide conveyors be integrated into bulk loading systems?

Yes. Air slide conveyors are commonly integrated into cement silo discharge systems, packing lines, and bulk loading systems to ensure continuous, stable, and dust-controlled powder transfer.

What is the difference between an air slide conveying system and a screw conveyor?

An air slide conveying system uses air fluidization and gravity for powder transport, while a screw conveyor relies on mechanical rotation. Air slide conveyors are more energy-efficient and wear-free for fine dry powders such as cement and fly ash.

Project Cases

LVRUI has delivered customized Air Slide Conveyor systems for cement plants, silo terminals, grinding units, and bulk powder projects in Asia, Europe, Africa, and South America.

Ready to Get a Reliable Air Slide Conveyor Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects