Metal Expansion Joint for Pipelines & Industrial Systems

(Sambungan Ekspansi Logam untuk Pipa & Sistem Industri)

Reliable stainless-steel metal expansion joints for absorbing thermal movement, vibration, and pipeline stress

Overview

Metal expansion joints (also called metal bellows, stainless steel expansion joints, or pipeline compensators) are designed to absorb thermal expansion, vibration, pressure pulsation, and equipment movement in industrial pipelines.

They protect pipelines from stress, prevent deformation, reduce noise, and ensure long-term safe operation in gas, air, dust, steam, and high-temperature applications.

Metal bellows expansion joint is widely used in power plants, chemical processing, HVAC systems, cement plants, steel mills, boilers, furnaces, dust extraction lines, and pneumatic conveying systems.

👉 Related system: Dust collection system for industrial plants

Common Types

To meet different working conditions, the following types are available:

✅ Single bellows expansion joint

✅ Double bellows expansion joint

✅ Universal expansion joint

✅ Gimbal and hinge type

✅ Flanged end expansion joint

✅ Welded end bellows joint

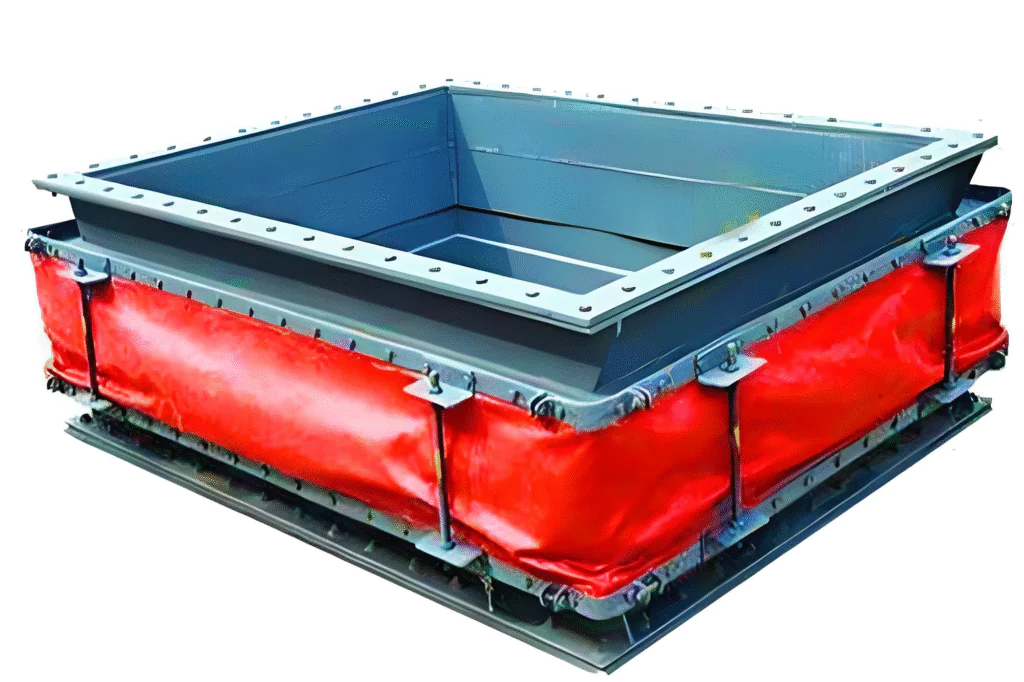

✅ Rectangular duct expansion joint

✅ High-temperature metal expansion joint

✅ Stainless steel 304 / 316L / Inconel bellows

✅ DN100 – DN3000 custom expansion joints

Technical Specifications

| Item | Specification |

|---|---|

| Diameter Range | DN100 – DN3000 |

| Temperature | ≤ 700°C (higher available) |

| Pressure Class | PN0.6 – PN2.5 |

| Bellows Material | SS304, SS316L, Inconel |

| Flange Standard | DIN / ANSI / JIS / Custom |

| Media | Air, dust, gas, steam |

*Technical specifications are for reference only and can be customized upon request.

Features

✅ Stainless steel bellows for high durability

✅ Temperature resistance up to 700°C

✅ Single-layer or multi-layer bellows construction

✅ Compensates thermal expansion and vibration

✅ High pressure and corrosion resistance

✅ Long service life in dusty and high-temperature environments

✅ Custom diameter, length, and flange standards

✅ Suitable for gas ducts, boilers, furnaces, blowers, compressors

✅ Ideal for industrial ventilation, pneumatic conveying, dust extraction

Working Principle

✅ Temperature rise causes expansion

✅ Metal bellows flex to absorb movement

✅ Prevents pipe deformation, cracking, and leakage

✅ Reduces vibration and mechanical stress

✅ Ensures continuous and safe system operation

Applications

✅ Air ducts & industrial ventilation

✅ Blower/inlet and outlet piping

✅ Boiler and furnace pipeline systems

✅ Cement, lime, and fly ash handling lines

✅ Chemical and refinery pipelines

✅ HVAC, exhaust gas ducts

✅ Pneumatic conveying systems

✅ Steel plants and power generation

✅ High-temperature and high-pressure pipelines

Advantages

✅ Excellent thermal expansion absorption

✅ Vibration and shock isolation

✅ Protects pipelines from stress and deformation

✅ Suitable for corrosive and abrasive environments

✅ Enhances pipeline safety and extends service life

✅ Custom-built for specific working conditions

✅ Multiple materials: SS304, SS316L, Inconel, high-alloy steel

FAQS About Metal Expansion Joint

What is a metal expansion joint used for?

A metal expansion joint is used to absorb thermal expansion, vibration, and mechanical displacement in pipelines, ducts, and industrial systems. It helps prevent pipe deformation, leakage, and equipment damage caused by temperature changes and pressure fluctuations.

What materials are used for metal expansion joints?

Metal expansion joints are typically made from stainless steel materials such as SS304, SS316L, Inconel, or high-alloy steel, depending on temperature, pressure, and corrosive conditions of the application.

Can metal expansion joints be customized?

Yes. LVRUI provides fully customized metal expansion joints, including diameter, length, flange standards, pressure class, and bellows structure to match specific industrial requirements.

What is the difference between metal expansion joints and fabric expansion joints?

Industrial expansion joint is suitable for high-pressure and high-temperature environments, while fabric expansion joints are mainly used for low-pressure dust or air duct systems. Selection depends on operating conditions.

Ready to Get a Reliable Metal Expansion Joint Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects