(EN)High-Efficiency Lump Breaker for Powder, Granules, and Bulk Material Processing

(ID)Mesin Pemecah Gumpalan Berkapasitas Tinggi untuk Pengolahan Bubuk, Granul, dan Material Curah

Introduction

In bulk material handling industries, powder agglomeration, hardened lumps, and material bridging can severely affect production efficiency. A high-quality lump breaker is essential for reducing oversized materials and ensuring smooth downstream conveying, feeding, mixing, and packaging operations.

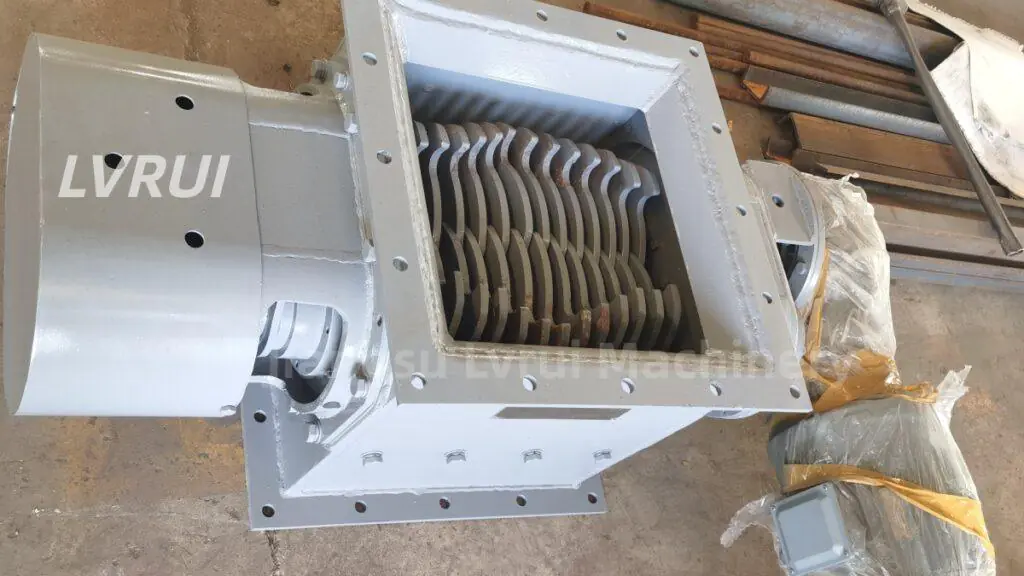

LVRUI offers a Heavy-Duty Industrial Lump Breaker designed for crushing hard lumps in powder, granules, chemical materials, cement, clinker, minerals, and food-grade applications.

This article covers the features, working principle, benefits, technical applications, and reasons why LVRUI’s lump breaker is the preferred solution for global powder processing systems.

What Is a Lump Breaker?

A lump breaker (also called clinker crusher, material crusher, powder grinder, bulk material crusher, agglomerate crusher, or de-lumping machine) is a mechanical crushing device used to break down compacted or hardened materials into smaller, more manageable particle sizes.

It is commonly used before:

- Screw conveyors

- Bucket elevators

- Bagging machines

- Mixers & blenders

- Silo discharge systems

- Pneumatic conveying systems

Key Features of LVRUI Industrial Lump Breaker

1. Heavy-Duty Construction

- Robust carbon-steel or stainless-steel body

- Industrial-grade bearings and shaft support

- Designed for 24/7 continuous operation

2. Precision Crushing Blades

- Intermeshing rotating blades

- Consistent particle size reduction

- Handles dry, semi-moist, and hardened lumps

3. Motor-Driven High Torque System

- Stable crushing force

- Energy-efficient operation

- Suitable for heavy-duty industrial applications

4. Easy Maintenance & Cleaning

- Quick-access housing

- Replaceable blades

- Reduced downtime

5. Customizable Options

- Single-shaft or dual-shaft lump breaker

- Explosion-proof motors (ATEX)

- Food-grade stainless steel

- Oversized inlet/outlet flanges

- Integration with silos, conveyors, feeders

Working Principle of the LVRUI Lump Breaker

The machine uses rotating blades to break up compacted materials. As material enters the inlet, the blades shear, crush, and reduce the size of clumps. The reduced particles then exit through the discharge flange, ready for feeding into downstream processes.

This ensures:

- Reliable material flow

- Prevention of clogging

- Improved efficiency of bucket elevators, screw conveyors, or bagging systems

- Stable dosing and feeding performance

Applications Across Industries

LVRUI lump breakers are widely used in:

- Cement & Building Materials → clinker, limestone, gypsum

- Chemical Industry → powder additives, plastic resin, polymers

- Food Processing → sugar, salt, starch, milk powder

- Mining & Minerals → kaolin, bentonite, quartz

- Agriculture & Fertilizers → urea, NPK, organic fertilizer

- Pharmaceuticals → granulated powders, compacted material

Advantages of Using an LVRUI Lump Breaker

- Eliminates material lumps for smooth flow

- Prevents blockages in conveyors & silos

- Enhances bagging accuracy

- Protects downstream equipment

- Reduces operational downtime

- Improves product consistency

- Compatible with automated bulk material systems

Why Choose LVRUI Lump Breaker?

LVRUI specializes in powder handling solutions including conveyors, packers, valves, loading spouts, big bag filling systems, and dust-free bulk material equipment.

Choosing LVRUI means:

- Strong R&D and engineering capability

- Durable heavy-duty machinery

- Custom-made solutions for your material type

- Global service and professional support

📞 Contact Our Engineering Team

Looking for a reliable Lump Breaker / Material Crushing Solution for your powder or bulk handling system?

Our engineers are ready to assist you with technical support, customized design, and complete system integration.

Email: lrst88@126.com

WhatsApp: +86 18261998937

✓ Free technical consultation

✓ Tailor-made equipment solutions

✓ Strong manufacturing capability

✓ Global export & technical support

We are ready to support your next project.