Telescopic Aggregate Loading Chute for Sand, Gravel & Stone Loading

(Chute Pemuat Agregat Teleskopik untuk Pasir, Kerikil & Batu)

Efficient Dust-Free Loading Solution for Bulk Sand, Gravel & Stone Handling

Overview

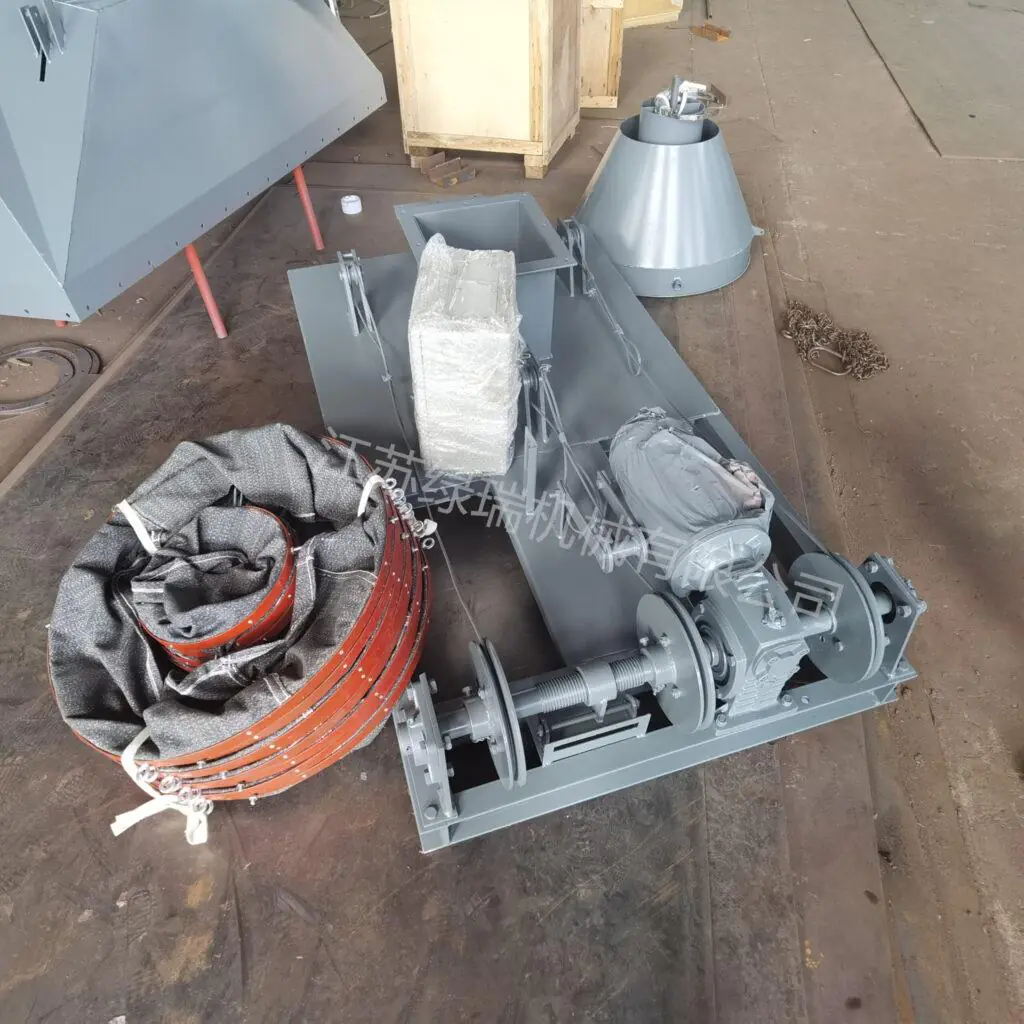

The aggregate loading chute is designed for clean, fast, and controlled loading of sand, gravel, crushed stone, limestone, and other bulk aggregates into trucks, railcars, or ships. Its telescopic cone structure reduces material drop height, minimizes dust generation, and improves loading efficiency in high-throughput aggregate handling operations.

This telescopic aggregate loading chute is widely used in quarries, aggregate plants, mining operations, cement plants, and construction material terminals, where dust-free loading and site cleanliness are critical requirements.

✅ Telescopic cone design for controlled aggregate discharge

✅ Reduced dust emission during truck and railcar loading

✅ Adjustable discharge height for different vehicle sizes

✅ Heavy-duty structure suitable for abrasive aggregates

Ideal for quarries, cement plants, aggregate plants, mining and construction terminals.

How Aggregate Loading Chutes Improve Bulk Material Handling

Aggregate loading chutes improve bulk material handling by controlling material flow and limiting free-fall height during loading operations. The telescopic structure allows the chute to extend into the truck or railcar, reducing impact velocity and airborne dust generation.

By combining adjustable discharge height, wear-resistant liners, and optional dust suppression systems, aggregate loading chutes:

✅ Improve site cleanliness at aggregate loading stations

✅ Reduce material spillage and product loss

✅ Protect equipment from excessive wear caused by abrasive aggregates

✅ Enhance operator safety and environmental compliance

This makes telescopic aggregate loading chutes a standard solution for modern aggregate terminals and quarry loading systems.

Features

✅ Heavy-duty steel body, wear-resistant liners

✅ Adjustable loading height for different truck sizes

✅ Telescopic discharge cone for focused material flow

✅ Optional dust hood and water spray dust suppression

✅ Smooth loading with reduced spillage

✅ Suitable for coarse and abrasive aggregates

✅ Designed for truck and railcar aggregate loading

✅ Suitable for high-impact, coarse, and abrasive materials

✅ Compatible with quarry conveyors and bulk storage silos

For controlled material discharge and dust-free conveying, aggregate loading chutes are often used together with air slide conveyor systems and flow control gate in cement and bulk material handling plants.

Technical Specifications

| Item | LRZSQ250 | LRZSQ300 | LRZSQ350 |

|---|---|---|---|

| Loading Capacity (t/h) | 100–300 | 200–600 | 300–1000 |

| Material Type | Sand / Gravel / Stone | Sand / Gravel / Stone | Sand / Gravel / Stone |

| Discharge Height (mm) | 2000–3500 | 2500–4000 | 3000–5000 |

| Telescopic Sections | 2 | 3 | 3–4 |

| Steel Thickness (mm) | 3–10 | 4–12 | 6–12 |

| Dust Control | Optional hood / water spray | Optional hood / water spray | Optional hood / water spray |

| Operation | Electric or manual | Electric or manual | Electric or manual |

*Technical specifications are for reference only and can be customized upon request.

Applicable Materials and Operating Conditions

Aggregate loading chutes are best suited for coarse and granular bulk materials such as sand, gravel, crushed stone, limestone, and similar aggregates. They are not intended for fine powders requiring fluidization, such as cement or fly ash, which typically use telescopic cement loading chutes instead.

Our telescopic aggregate loading chutes are available in multiple sizes for sand, gravel and stone with adjustable cone sections, electric or manual drive, and optional dust-control systems.

Bulk density and material flow characteristics reference: Engineering Toolbox – Conveyor Material Data.

FAQs About Aggregate Loading Chute System

What materials can an aggregate loading chute handle?

loading chute system is designed for handling bulk materials such as sand, gravel, crushed stone, limestone, clinker, and other coarse aggregates. It is widely used in quarries, cement plants, mining sites, and aggregate terminals.

How does an aggregate loading chute reduce dust during loading?

The aggregate loading chute uses a telescopic design combined with optional dust suppression systems such as dust hoods or water spray. This reduces free-fall height, minimizes airborne dust, and improves environmental safety during truck or railcar loading.

Is the aggregate loading chute customizable for different truck sizes?

Yes. LVRUI bulk loading chute is available with adjustable discharge heights, multiple telescopic sections, and custom inlet sizes to suit different truck, railcar, or vessel loading requirements.

What equipment is commonly used together with aggregate loading chutes?

Aggregate loading chutes are often integrated with bulk material handling equipment such as air slide conveyor systems, flow control gate valves, and bulk storage silos to ensure smooth, controlled, and dust-free material transfer.

What is the difference between an aggregate loading chute and a cement loading chute?

Aggregate loading chutes are designed for coarse, abrasive materials such as sand, gravel, and crushed stone, focusing on impact resistance and dust reduction. Cement loading chutes are designed for fine powders and emphasize air sealing and dust containment rather than impact protection.

Ready to Get a Reliable Aggregate Loading Chute Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects