Dust-Free Cement Bulk Loader for Silo & Truck Loading

(Sistem pemuatan semen curah tanpa debu untuk silo dan truk)

Sealed bulk cement loading system for trucks and tankers with accurate control and minimal dust emission

Overview

The cement bulk loader is designed for fast and dust-free loading of bulk cement, fly ash, and fine powder materials into trucks or tankers. By integrating sealed loading chutes, flow control gates, and dust collection systems, it ensures clean operation, accurate material transfer, and reduced material loss during bulk cement loading.

As a key component of modern cement silo bottom discharge systems, cement bulk loaders enable controlled and environmentally compliant bulk loading operations in cement plants, fly ash handling facilities, and bulk powder terminals. The system is widely used where dust control, loading accuracy, and operational safety are critical requirements.

For efficient powder conveying before bulk loading, the Air Slide Conveyor is commonly integrated to ensure stable and continuous material flow.

For dust control during cement loading operations, the Dust-Free Loading Spout is used to minimize dust emission and material loss.

Features

✅ Fully sealed cement bulk loading loading to control dust

✅ Automatic level switch for bulk cement truck loading

✅ Dust collector and air return system for cement silo loading

✅ High-accuracy weighing for bulk cement transfer

✅ Suitable for cement, fly ash, lime powder

✅ Customized loading length for different cement silo heights

✅ Designed for sealed silo bottom cement loading

✅ Supports accurate bulk cement truck and tanker loading

✅ Reduces dust emission and improves loading site cleanliness

LVRUI Cement Bulk Loader works together with our Flow Control Gate and Bag Filter systems to ensure smooth and dust-free loading. Learn more:

The cement bulk loader works together with Flow Control Gates for accurate material regulation and Bag Filter Dust Collectors to ensure dust-free bulk loading operations.

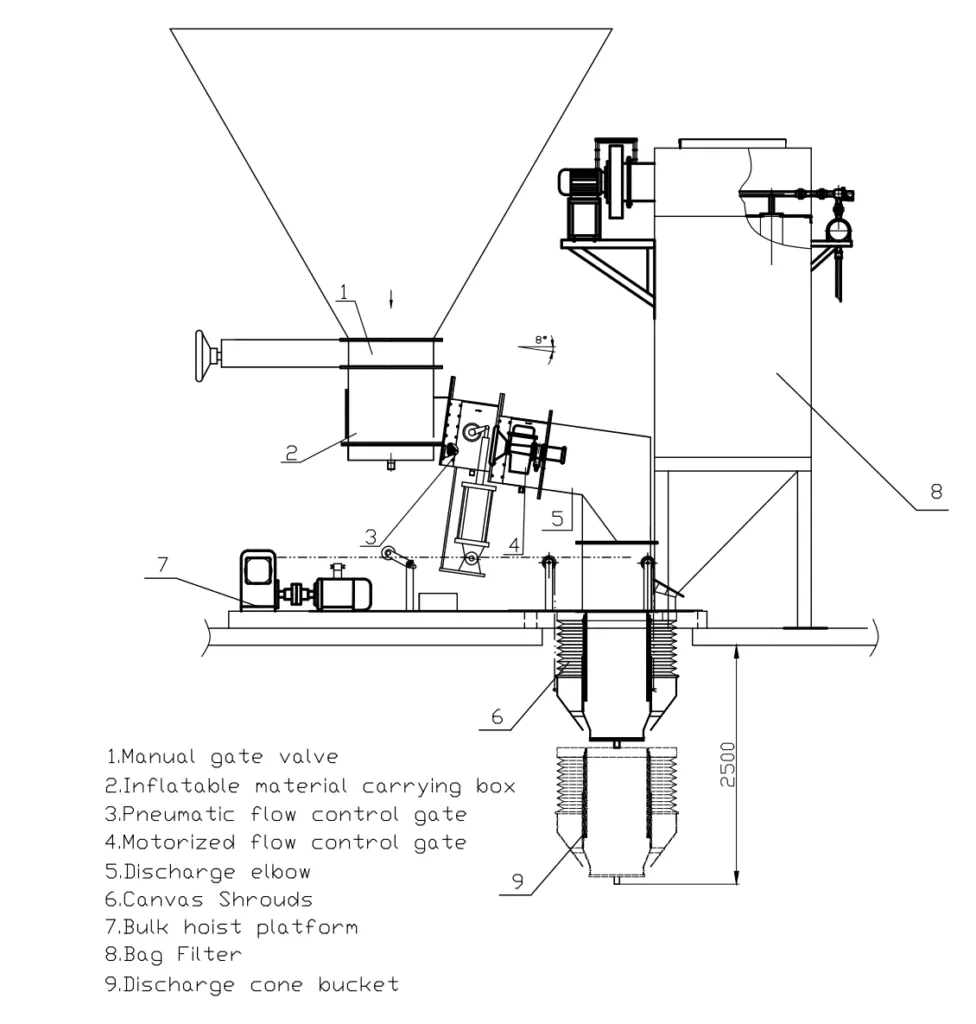

Working Principle

The cement bulk loader operates by connecting directly to the silo bottom discharge outlet. During loading, cement flows through the flow control gate and discharge chute into the bulk truck. A flexible canvas shroud and bag filter system work together to collect dust generated during loading, ensuring a clean and controlled bulk cement loading process.

By combining controlled material discharge and enclosed dust collection, the cement bulk loader maintains stable bulk cement flow while minimizing airborne dust during truck and tanker loading operations.

Technical Specification

| Item | ZSQ150-I (Under Silo) | ZSQ150-II (Side of Silo) |

|---|---|---|

| Loading Capacity (t/h) | 60–300 | 60–300 |

| Drop Height (m) | 1.5–5 | 1.5–5 |

| Loading Head Lifting Speed (m/s) | 0.19 | 0.19 |

| Chute Working Air Pressure (Pa) | — | 3.5–5.5×10³ |

| Chute Working Air Volume (m³/min) | 2.5–4.5×10³ | 2.5–4.5×10³ |

| Level Sensor Air Volume (m³/min) | 0.025–0.05 | 0.025–0.05 |

Loading capacity, chute length, and air consumption should be selected based on cement type, silo height, loading rate, and site layout. Proper configuration of cement bulk loader parameters ensures efficient loading performance, reduced dust emission, and long-term operational reliability.

This cement bulk loader specification is suitable for various cement silo bottom bulk loading applications. All parameters can be customized according to cement type, silo height, loading capacity, and site conditions.

Application

✅ Cement grinding stations

✅ Bulk cement truck loading stations

✅ Fly ash loading terminals

✅ Silo bottom discharge systems

✅ Cement storage and distribution plants

Cement bulk loaders are widely installed at silo bottoms in cement plants, grinding stations, and bulk powder terminals for dust-free bulk cement loading into trucks or tankers. As a key component of cement silo bottom discharge systems, they are used where accurate material transfer, effective dust control, and stable bulk cement loading operations are required.

The cement bulk loader integrates seamlessly with LVRUI Powder Handling Equipment, enabling flexible system configuration for bulk cement storage, conveying, and loading applications.

Our cement bulk loading systems comply with international dust emission standards, including U.S. EPA guidelines for industrial dust control.

Why Choose LVRUI Cement Bulk Loader?

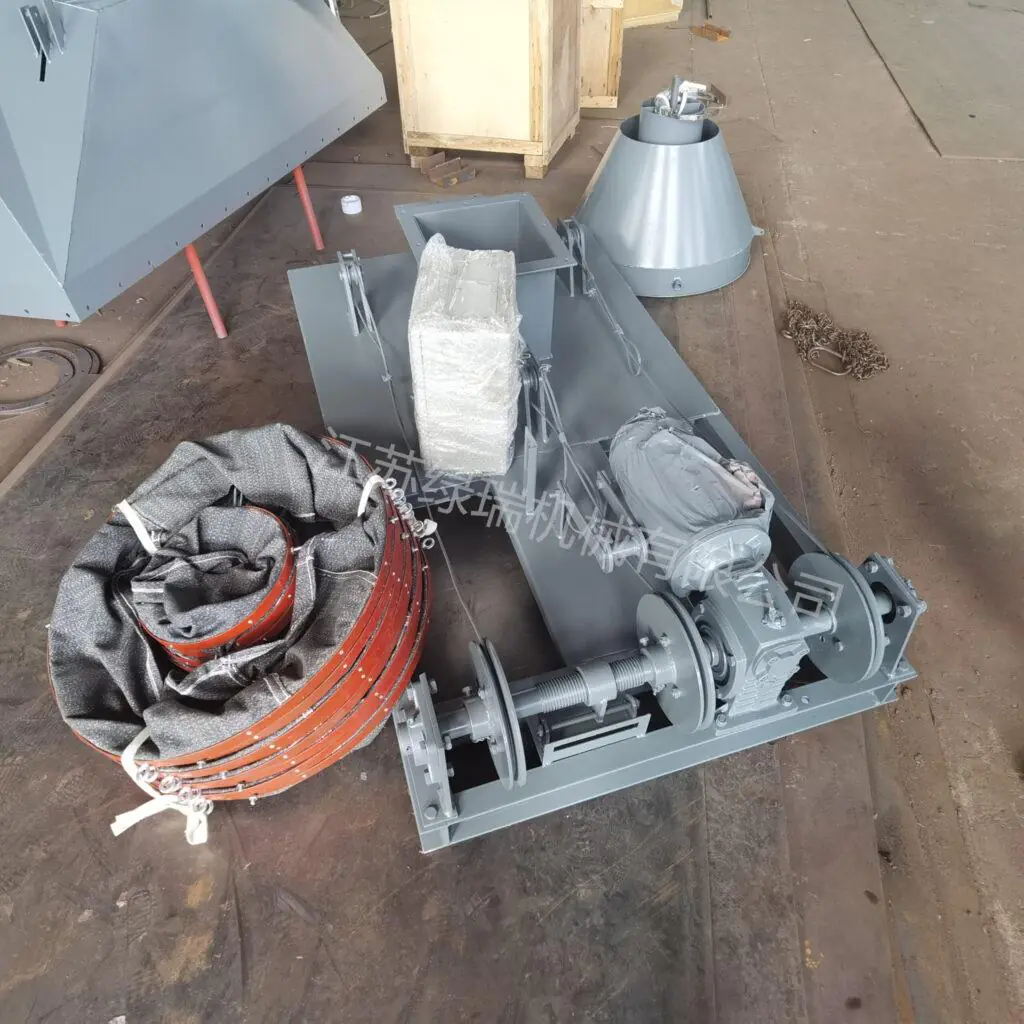

LVRUI bulk cement loading system is designed based on years of experience in bulk material handling equipment. Each system integrates flow control gates, dust collection, and flexible loading components to ensure stable performance, minimal dust emission, and long service life.The system is suitable for both under-silo and side-silo bulk cement loading layouts, and can be integrated with bag filters, flow control gates, and automated loading systems.

✅ Designed for cement silo bottom loading

✅ Reliable bulk cement truck loading system

✅ Compatible with bag filter and dust control system

✅ Customized for different cement plants and layouts

FAQs About Cement Bulk Loader

Below are common questions about cement bulk loader systems, silo bottom bulk loading, and dust-free cement loading operations.

What materials can be handled by a cement bulk loader?

Cement, fly ash, lime powder, and other fine bulk powders.

Can the cement bulk loader be used for silo bottom discharge?

Yes, it is specifically designed for cement silo bottom bulk loading.

How does the dust-free cement bulk loading system work?

The system combines sealed loading spouts, canvas shrouds, and bag filters to control dust.

Is the cement bulk loader suitable for automated bulk loading systems?

Yes, it can be integrated with automatic control systems, level sensors, and dust collectors for fully automated bulk cement loading operations.

What is the difference between a cement bulk loader and a telescopic loading chute?

A cement bulk loader is designed for sealed, dust-free bulk cement loading from silo bottoms with integrated weighing and dust collection, while a telescopic loading chute is mainly used for open bulk material loading into trucks or containers. Cement bulk loaders are preferred for accurate, enclosed, and automated cement loading systems.

When should a cement bulk loader be used instead of a telescopic loading chute?

A cement bulk loader is preferred for sealed, dust-free loading from silo bottoms with integrated dust collection and flow control, while telescopic loading chutes are typically used for open bulk material loading applications where full enclosure is not required.

Ready to Get a Reliable Cement Bulk Loader Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects