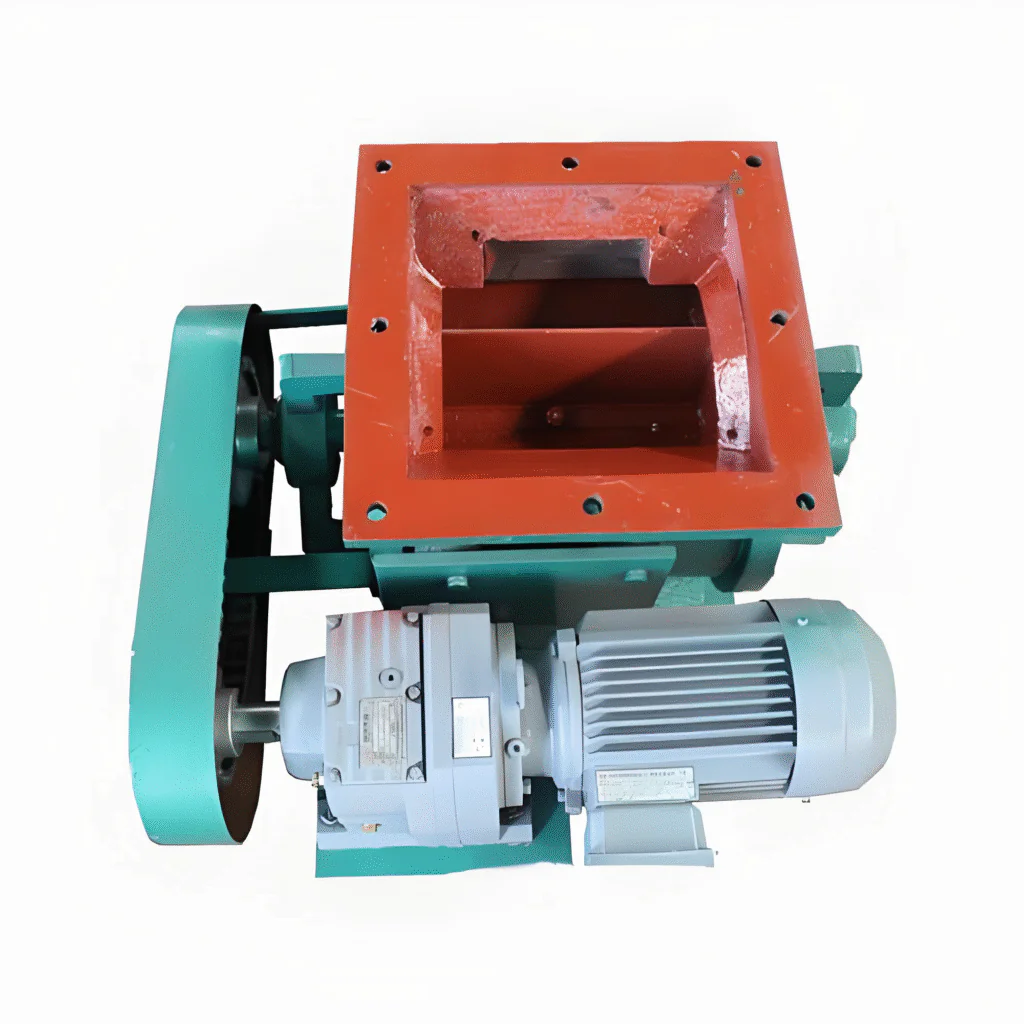

Star Discharge Valve for Dust-Free Powder Feeding

(Katup Pembuangan Bintang untuk Pengumpanan Bubuk Bebas Debu)

Stable airlock control for continuous material discharge

Overview

The star discharge valve, also known as a rotary airlock valve or rotary feeder, is an industrial feeding device installed under silos, hoppers, dust collectors, and bag filters to ensure dust-free powder discharge and stable material feeding.

By maintaining an airtight airlock structure, the star discharge valve prevents air leakage and material backflow while allowing continuous and controlled discharge. It is widely used in cement plants, fly ash handling systems, pneumatic conveying lines, and industrial powder processing applications where pressure balance and clean operation are critical.

For related bulk material feeding equipment, see our Motorized Flow Control Gate and Air Slide Conveyor.

Features

✅ Cast iron / carbon steel / stainless steel housing options

✅ Wear-resistant rotor blades for long service life

✅ Airtight airlock design prevents air leakage

✅ Smooth rotation with low noise

✅ Suitable for powders and small granules

✅ Supports pneumatic conveying and bag filters

Working Principle

Powder drops into the rotating pockets of the valve. The rotor, driven by a motor, continuously feeds material to the outlet in a controlled, dust-free manner. The airlock structure maintains pressure stability, improves discharge accuracy, and prevents leakage.

As a rotary airlock valve, the star discharge valve functions as a pressure-sealing feeder. While powder drops into the rotor pockets by gravity, the rotating blades isolate material flow from system air pressure. This design makes the valve especially suitable for dust collector discharge, pneumatic conveying systems, and applications requiring stable airlock performance.

Learn more about the working principle of a rotary airlock valve from this Wikipedia reference.

Technical Specifications

| Item | LRB150 | LRB200 | LRB250 |

|---|---|---|---|

| Inlet Size (mm) | 150×150 | 200×200 | 250×250 |

| Capacity (m³/h) | 10–30 | 20–60 | 40–100 |

| Rotor Speed (rpm) | 10–30 | 10–30 | 10–30 |

| Material | Cast Iron / Carbon Steel / SS304 | Cast Iron / Carbon Steel / SS304 | Cast Iron / Carbon Steel / SS304 |

| Drive Motor | 0.75–1.1 kW | 1.1–1.5 kW | 1.5–2.2 kW |

| Application | Powder / Granule | Powder / Granule | Powder / Granule |

*Technical specifications are for reference only and can be customized upon request.

The above star discharge valve specifications are typical configurations. Rotor size, material, blade clearance, and motor power can be customized for different powders, flow rates, and pressure conditions.

Applications

✅ Cement plants and cement powder feeding systems

✅ Fly ash and industrial powder systems

✅ Dust collectors & bag filter discharge in dust control systems

✅ Pneumatic conveying systems for fly ash and fine powders

✅ Silo bottom and hopper feeding

Advantages

✅ Dust-free discharge with airtight airlock design

✅ Prevents air leakage and material backflow

✅ Stable feeding without clogging or bridging

✅ Long lifespan with low maintenance requirements

✅ Compact structure, easy installation

FAQS About Star Discharge Valves

What is a star discharge valve used for?

A star discharge valve is used to discharge powder or granular material from silos, hoppers, dust collectors, and bag filters while maintaining an airtight seal. It ensures dust-free feeding and stable material flow in pneumatic conveying and dust control systems.

Is a star discharge valve the same as a rotary airlock valve?

Yes. A star discharge valve is commonly referred to as a rotary airlock valve or rotary feeder valve. These terms describe the same working principle based on a rotating rotor that maintains pressure balance during material discharge.

Can a star discharge valve be used under a dust collector?

Yes. Star discharge valves are widely installed under dust collectors and bag filters to prevent air leakage and dust emission while continuously discharging collected powder.

What materials can a star discharge valve handle?

Star discharge valves are suitable for cement, fly ash, limestone powder, chemical powders, and fine granular materials. Rotor design and clearance can be customized for abrasive or fine powders.

How do I choose the right star discharge valve size?

Valve size selection depends on material bulk density, required capacity, particle size, and system pressure. LVRUI engineers can recommend the optimal rotary airlock valve size based on your operating conditions.

Need a reliable star discharge valve for your powder handling system?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects