Bulk loaders are essential equipment for fast, dust-free loading of cement, fly ash, clinker, minerals, and other powder materials. Learn the main applications of bulk loading systems in cement plants, storage terminals, logistics centers, and industrial material handling.

Bulk Loader Applications: Key Industries and Material Handling Scenarios

A bulk loader—also known as a cement bulk loading machine or loading spout—is essential equipment for the efficient and dust-free loading of powder and granular materials. It is widely used in cement plants, bulk material terminals, silo discharge systems, and industrial production lines that require fast and controlled loading of trucks, tankers, ships, or rail wagons.

This article provides a complete overview of the main application scenarios, materials, and industries where bulk loaders play a critical role.

1. Cement Plants and Grinding Stations

Bulk loaders are most commonly used in the cement industry, including:

- Cement production plants

- Clinker grinding stations

- Cement packing and loading terminals

- Fly ash and cement silo systems

Typical materials:

- Cement powder

- Clinker dust

- Fly ash

- Slag powder

- Limestone powder

Bulk loaders allow fast, safe, and dust-free loading into tanker trucks, ensuring accurate material flow and minimizing emission.

2. Fly Ash Handling & Power Plants

Fly ash is a fine powder that easily escapes into the air. Bulk loaders with dust collection systems provide:

- Cleaner loading operations

- Controlled discharge

- Reduced environmental pollution

- Improved loading efficiency

Industries include:

- Coal-fired power plants

- Fly ash collection stations

- Fly ash transfer and storage terminals

3. Dry Mortar and Construction Materials Industry

Bulk loading systems are widely used in:

- Dry mortar production

- Plaster powder

- Gypsum powder

- Ceramic raw materials

- Construction chemicals

These materials require fast and stable flow control, making bulk loaders essential for material distribution.

4. Mining and Mineral Processing

Bulk loaders are used for loading:

- Limestone powder

- Dolomite powder

- Bentonite

- Talc powder

- Silica powder

- Other fine mineral materials

The equipment helps maintain consistent discharge rate, suitable for bulk storage yards and mineral terminals.

5. Chemical and Pharmaceutical Powders

In factories with strict hygiene or anti-contamination requirements, bulk loaders ensure:

- Controlled powder transfer

- Reduced material waste

- Closed and dust-free loading

Typical applications:

- Chemical raw material silos

- Polymer powder storage

- Additives and pigments

- Fertilizer powder transportation

6. Food and Agriculture Industry

Bulk loaders are used to load:

- Flour

- Starch

- Grain powder

- Feed materials

- Cornmeal

- Additive powders

Food-grade bulk loaders can be designed with stainless steel, smooth surfaces, and sanitary standards.

7. Logistics, Ports, and Bulk Material Terminals

Large-scale terminals require efficient and automated loading systems for transporting powder materials via:

- Ship loaders

- Rail car bulk loading systems

- Container loading stations

- Truck tanker loading platforms

Bulk loaders ensure continuous and high-capacity loading operations.

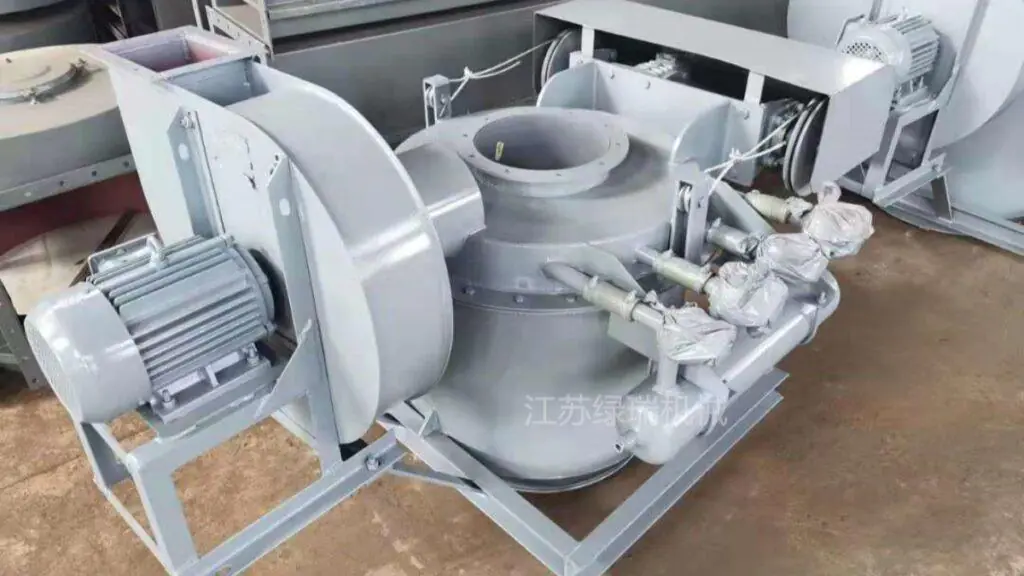

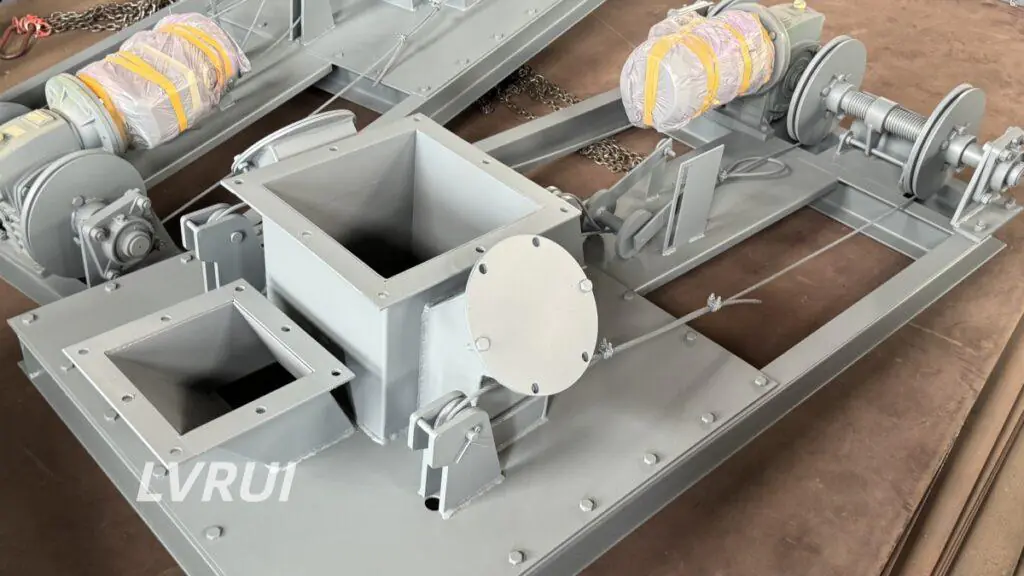

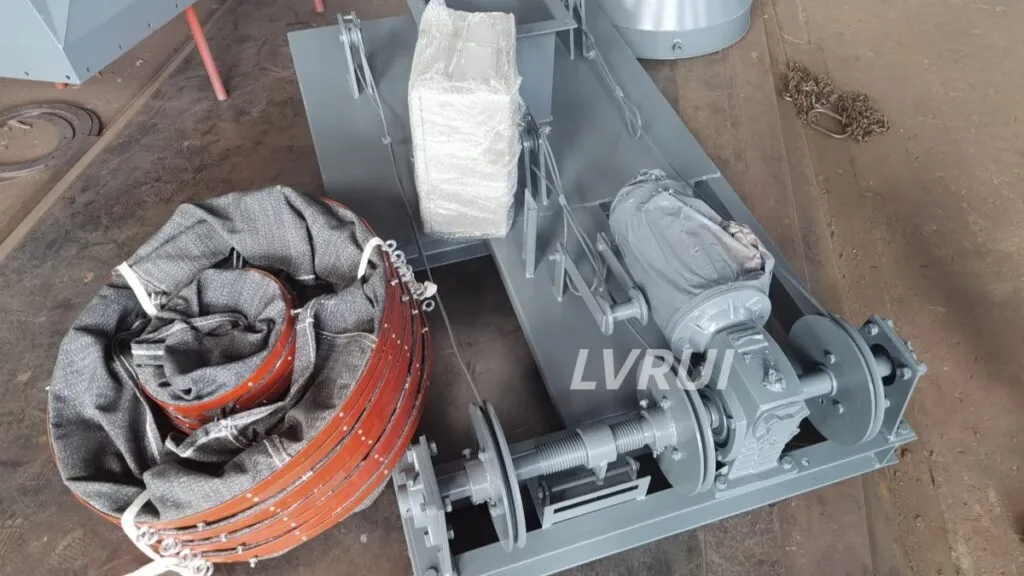

8. Silo Discharge and Pneumatic Conveying Systems

Bulk loaders often work together with:

- Air slide conveyors

- Screw conveyors

- Rotary valves

- Flow control gates

- Bag filters

This combination provides a complete solution for material storage, discharge, and loading.

Benefits of Using Bulk Loaders

✔ Dust-Free Loading

Built-in dust collection protects workers and the environment.

✔ High Loading Efficiency

Fast discharge rate shortens truck loading time.

✔ Automatic Level Detection

Prevents overfilling and improves safety.

✔ Wide Material Compatibility

Handles all powder and fine granular materials.

✔ Long Service Life

Heavy-duty design, wear-resistant components.

Conclusion

Bulk loaders play an essential role in modern bulk material handling systems. From cement plants to chemical factories, mining, agriculture, and logistics terminals, bulk loaders provide clean, safe, and efficient loading operations for a wide range of powder materials.

Choosing a reliable bulk loading system can significantly improve production efficiency, reduce dust emissions, and ensure safe transportation.

If you need customized bulk loading solutions for cement, fly ash, minerals, or industrial powder materials, feel free to contact us for professional support.