(EN)How Dust Control Technology Works in Telescopic Loading Chute Systems

(ID)Cara Kerja Teknologi Pengendalian Debu pada Sistem Telescopic Loading Chute

Introduction

Dust-free bulk material loading is a critical requirement in cement plants and bulk handling facilities.

how telescopic loading chutes achieve dust-free bulk material loading is explained in this article through enclosed structures, controlled material flow, and integrated dust collection systems.

Dust emissions during bulk material loading not only cause material loss but also create serious environmental and safety challenges in cement plants, power stations, and bulk terminals.

Telescopic loading chutes are specifically engineered to address this problem, offering a practical and proven solution for dust-free bulk material loading.

Unlike general product specification pages, this article focuses on how telescopic loading chutes achieve dust-free loading in real industrial applications, explaining the dust control principles, system design, and operational mechanisms behind their performance.

🔗 What Is a Telescopic Loading Chute? Working Principle & Applications

1. Enclosed Telescopic Structure for Dust Containment

One of the key reasons telescopic loading chutes can achieve dust-free loading is their fully enclosed telescopic structure.

How it works:

- The chute extends downward toward the truck, ship, or silo

- Material falls inside a sealed passage instead of open air

- Dust is contained within the chute body

This design prevents dust from escaping into the surrounding environment, especially during high-volume powder loading.

2. Controlled Material Flow Reduces Dust Generation

Dust is often generated when material free-falls at high speed.

Telescopic loading chutes reduce dust formation by controlling material flow velocity.

Key mechanisms:

- Material-guiding cones or spirals slow down the falling speed

- Even material distribution minimizes turbulence

- Reduced impact force lowers dust release at discharge points

🔗 The importance of controlled gravity flow is emphasized by the Conveyor Equipment Manufacturers Association (CEMA):

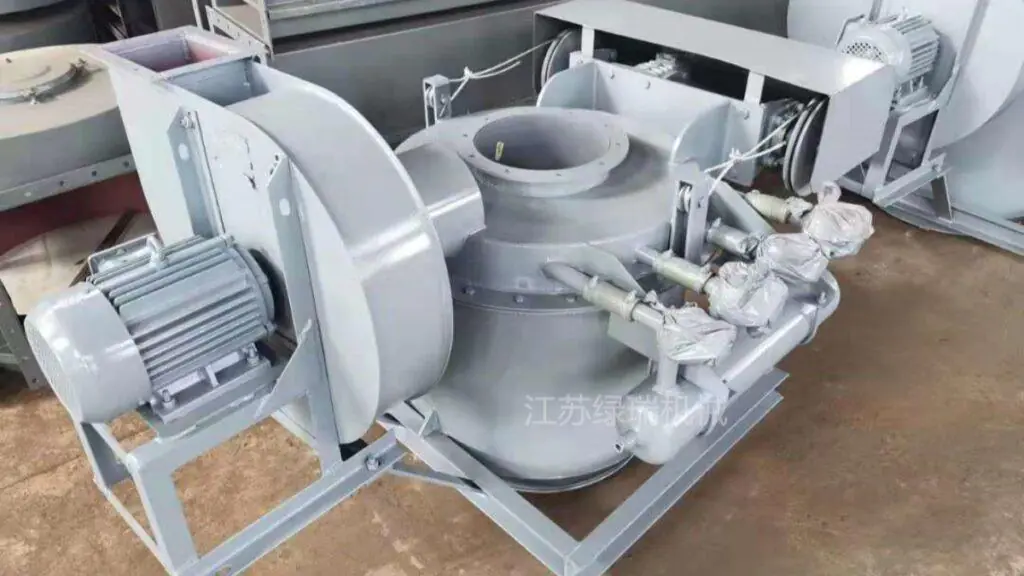

3. Integrated Dust Collection System

Most telescopic loading chutes are equipped with built-in dust extraction connections.

Dust collection process:

- Fine dust is extracted through suction ports

- Dust-laden air is directed to a dust collector or filter

- Clean air is released back into the system

This integrated design ensures that airborne particles are removed directly at the source.

🔗 OSHA highlights source-level dust control as a critical measure for bulk material handling safety.

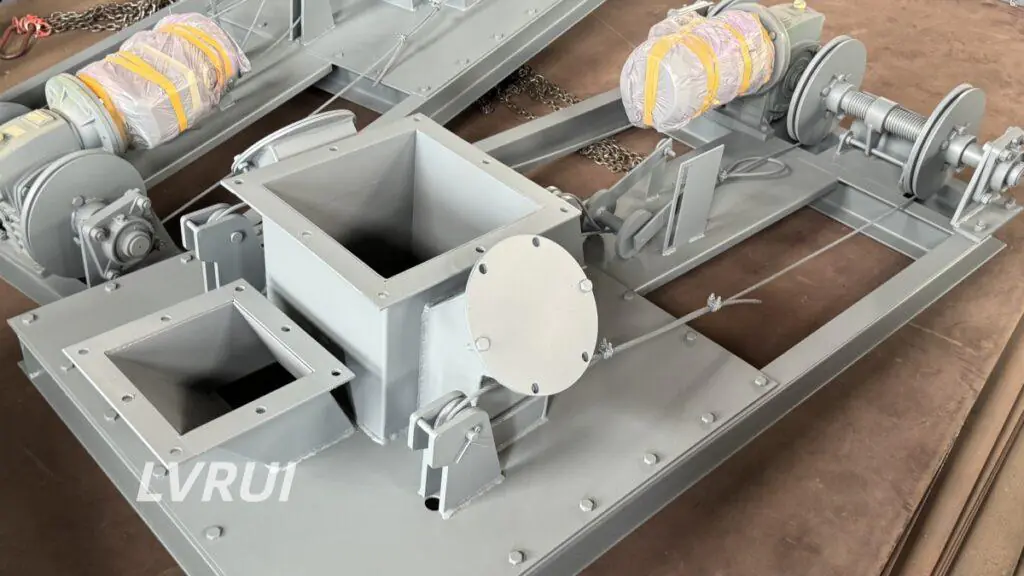

4. Automatic Height Adjustment Maintains a Sealed Loading Zone

Telescopic loading chutes automatically adjust their length during loading operations.

Benefits:

- The chute remains close to the material surface

- Minimizes the open gap where dust can escape

- Maintains a stable, enclosed loading zone

This feature is especially important when loading trucks or ships with varying fill levels.

5. Flexible Sealing Components Prevent Dust Leakage

Flexible components such as rubber skirts or sealing cones play a crucial role in dust control.

Their function:

- Create a soft seal between chute and material pile

- Adapt to uneven surfaces

- Prevent dust from escaping at the discharge point

🔗 Basic dust containment and air movement concepts are explained under fluidization theory

Typical Applications of Dust-Free Telescopic Loading Chutes

Telescopic loading chutes are commonly used in:

- Cement powder loading systems

- Fly ash and power plant bulk loading

- Grain and agricultural terminals

- Mining and mineral processing facilities

- Chemical powder handling operations

🔗 Bulk Loader Applications: Where Cement & Powder Bulk Loading Systems Are Used.

This article focuses on how telescopic loading chutes achieve dust-free bulk material loading through structural design and dust control technology.

Frequently Asked Questions (FAQ)

Q1: How does a telescopic loading chute reduce dust compared to an open chute?

By enclosing the material flow, controlling discharge speed, and integrating dust extraction, telescopic loading chutes prevent dust from escaping into the air.

Q2: Can telescopic loading chutes be used for cement and fly ash?

Yes. They are widely used for fine powders such as cement, fly ash, limestone powder, and other bulk solids.

Q3: Do telescopic loading chutes require additional dust collectors?

Most systems are designed to connect directly to centralized dust collection systems for maximum efficiency.

Conclusion

Understanding how telescopic loading chutes achieve dust-free bulk material loading helps engineers improve safety, efficiency, and environmental performance in bulk handling operations.

Telescopic loading chutes achieve dust-free bulk material loading through a combination of enclosed structure, controlled material flow, integrated dust collection, and flexible sealing systems.

When properly designed and installed, they significantly improve environmental performance, operational safety, and material handling efficiency in bulk loading operations.

Need a Reliable Telescopic Loading Chute for Dust-Free Bulk Loading?

LVRUI specializes in custom-designed telescopic loading chute systems for cement plants, ports, and bulk material handling facilities worldwide.

📧 Email: lrst88@126.com

🌐 Website: https://lvrui-conveyor.com

Contact LVRUI today to achieve cleaner, safer, and more efficient bulk material loading.

Indonesian Short Version

Telescopic loading chute digunakan untuk mengurangi debu selama proses pemuatan material curah seperti semen dan fly ash. Dengan desain tertutup, pengaturan aliran material, sistem penghisap debu terintegrasi, dan komponen penyegel fleksibel, sistem ini mampu menjaga lingkungan kerja tetap bersih dan aman. Telescopic loading chute merupakan solusi efektif untuk pemuatan material curah bebas debu di berbagai industri.