Dust-Free High-Temperature Bulk Loading System for Hot Cement Clinker

(Pemuat Curah Klinker – Sistem Pemuatan Suhu Tinggi Tanpa Debu)

Designed for safe and efficient loading of hot cement clinker into trucks, hoppers, and bulk carriers

Overview

The clinker bulk loader is designed for fast, safe, and dust-free loading of hot clinker into trucks, hoppers, railcars, and bulk carriers.

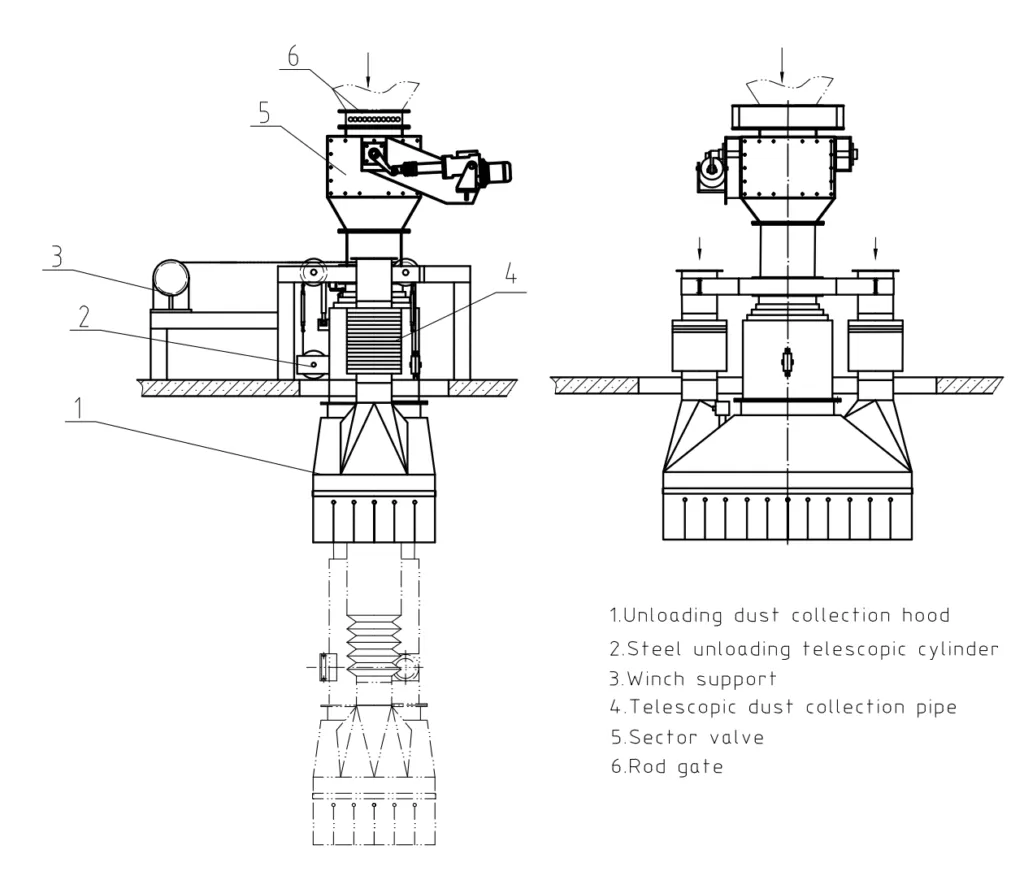

Featuring heat-resistant steel structures, telescopic discharge sections, and integrated dust extraction, it ensures stable material flow and reduced emissions in cement plants and terminals.

In clinker handling systems, the clinker bulk loader serves as a dedicated solution for transferring hot clinker materials from silo discharge points to bulk transport equipment. Compared with conventional cement bulk loaders, clinker loading systems require reinforced structures, heat-resistant components, and reliable dust control to ensure safe and stable operation.

Key Benefits

✅ High-temperature resistant wear plates and sealing components

✅ Telescopic loading chute suitable for varying truck heights

✅ Integrated dust extraction and air return design

✅ Stable discharge with minimal material spillage

✅ Designed for continuous operation in harsh cement plant environments

Ideal for hot clinker handling applications requiring safe loading, low dust emission, and long-term operational stability.

Advantages

✅ High-temperature resistant telescopic loading chute

✅ Dust collector with air return reduces emissions

✅ Automatic level control—stops loading when full

✅ Telescopic design for different truck heights

✅ Fast loading speed and continuous operation

✅ Strong sealing—minimal wear and maintenance

Designed specifically for hot clinker bulk loading with high-temperature resistant structure

For dust-free truck loading applications, the clinker bulk loader can be integrated with our Loading Bellows system to ensure effective dust sealing during hot clinker discharge.

Typical High-Temperature Clinker Handling Scenarios

LVRUI clinker bulk loaders are widely used in high-temperature clinker handling scenarios across cement plants, grinding stations, and port terminals. Below are typical application conditions and system configurations.

Under Clinker Silo Discharge

Clinker bulk loaders are commonly installed under clinker silos or storage bins for direct truck or hopper loading.

The system is designed to withstand high clinker temperatures while ensuring stable flow control and effective dust sealing during discharge.

Typical features include reinforced telescopic chute structure, high-temperature resistant sealing materials, and interlock control with silo discharge gates to ensure safe and dust-free operation.

Clinker Storage Hall Truck Loading

In clinker storage halls, the clinker bulk loader enables controlled loading of hot clinker into trucks after intermediate storage.

The telescopic loading chute adapts to different truck heights, while the integrated dust extraction system minimizes dust emissions during loading.

This configuration is suitable for cement plants requiring flexible truck loading positions and efficient dust control inside enclosed storage buildings.

Port / Terminal Hot Clinker Export

For port terminals and export facilities, clinker bulk loaders are used for loading hot clinker into trucks or bulk carriers for downstream transportation.

The system supports continuous operation and high loading capacity, making it ideal for large-scale clinker export projects.

Special designs can be provided to meet port environmental standards, including enhanced dust collection, corrosion-resistant structures, and integration with terminal conveying systems.

Grinding Station Clinker Feeding

Clinker bulk loaders are also applied at cement grinding stations to feed hot clinker from transport trucks or intermediate storage into receiving hoppers.

The controlled loading process reduces material spillage and ensures smooth downstream conveying to crushers or grinding systems.

This application is suitable for grinding plants handling externally supplied clinker with temperature and dust control requirements.

Depending on site layout, clinker temperature, loading capacity, and environmental requirements, LVRUI provides customized clinker bulk loading solutions tailored to each application scenario.

Working Principle

✅ The truck positions under the loading chute

✅ The loading chute lowers to seal with the truck inlet

✅ Clinker flows smoothly into the truck or hopper

✅ Dust is extracted and filtered during loading

✅ Level sensors detect full load and automatically stop feeding

✅ The chute retracts after loading is complete

This sequence ensures clean, controlled, and efficient transfer of hot clinker materials during bulk loading operations.

This working principle ensures safe, dust-free, and continuous bulk loading of hot clinker materials under demanding cement plant operating conditions.

For a detailed explanation of clinker production principles in cement manufacturing, refer to this Britannica overview on cement clinker.

Technical Specifications

| Item | Clinker Bulk Loader |

|---|---|

| Loading Capacity (t/h) | 100–800 |

| Material Temperature | ≤ 250°C (Higher temperature optional) |

| Telescopic Chute Length (mm) | 1200–4500 |

| Dust Collector Air Volume (m³/h) | 5500–9500 |

| Level Control | Capacitive level switch |

| Installation Position | Under silo / steel platform |

| Power Supply | 380V / 440V (customizable) |

*Technical specifications are for reference only and can be customized upon request.

Applications

✅ Cement production plants

✅ Clinker storage and handling terminals

✅ Grinding stations and material transfer points

✅ Port bulk loading systems

✅ High-temperature bulk material handling processes

Related Products You May Need:

Air Slide Conveyor System – Ideal for transporting clinker to loading points.

Loading Bellows for Dust-Free Truck Loading – Works with clinker for sealed loading.

Why Choose LVRUI Clinker Bulk Loader?

LVRUI provides engineered solutions for high-temperature bulk material handling, addressing the specific challenges of clinker discharge, dust control, and continuous operation.

✅ Designed for high-temperature clinker bulk loading

✅ Reliable dust-free clinker loading system

✅ Suitable for under-silo and platform installations

✅ Customized for different cement plant layouts

FAQs About Clinker Bulk Loader

What materials can be handled by a clinker bulk loader?

A clinker bulk loader is designed specifically for hot cement clinker. It can also handle other high-temperature bulk materials with similar physical properties, depending on system configuration.

What is the maximum material temperature for clinker bulk loading?

Standard clinker bulk loaders are designed for material temperatures up to 250°C. Higher temperature-resistant designs can be provided based on project requirements.

What is the difference between a clinker bulk loader and a cement bulk loader?

A clinker bulk loader is engineered for high-temperature materials and features reinforced structures, heat-resistant components, and enhanced sealing. Cement bulk loaders are typically used for ambient-temperature powdered materials.

Can the clinker bulk loader be used for silo bottom discharge?

Yes. The clinker bulk loader is commonly installed under clinker silos or storage bins for direct bulk loading into trucks, hoppers, or bulk carriers.

How is dust controlled during hot clinker bulk loading?

The system combines a sealed loading chute, telescopic dust collection pipe, and integrated dust extraction system to control dust emissions during high-temperature clinker loading operations.

Ready to Get a Reliable Clinker Bulk Loader Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects