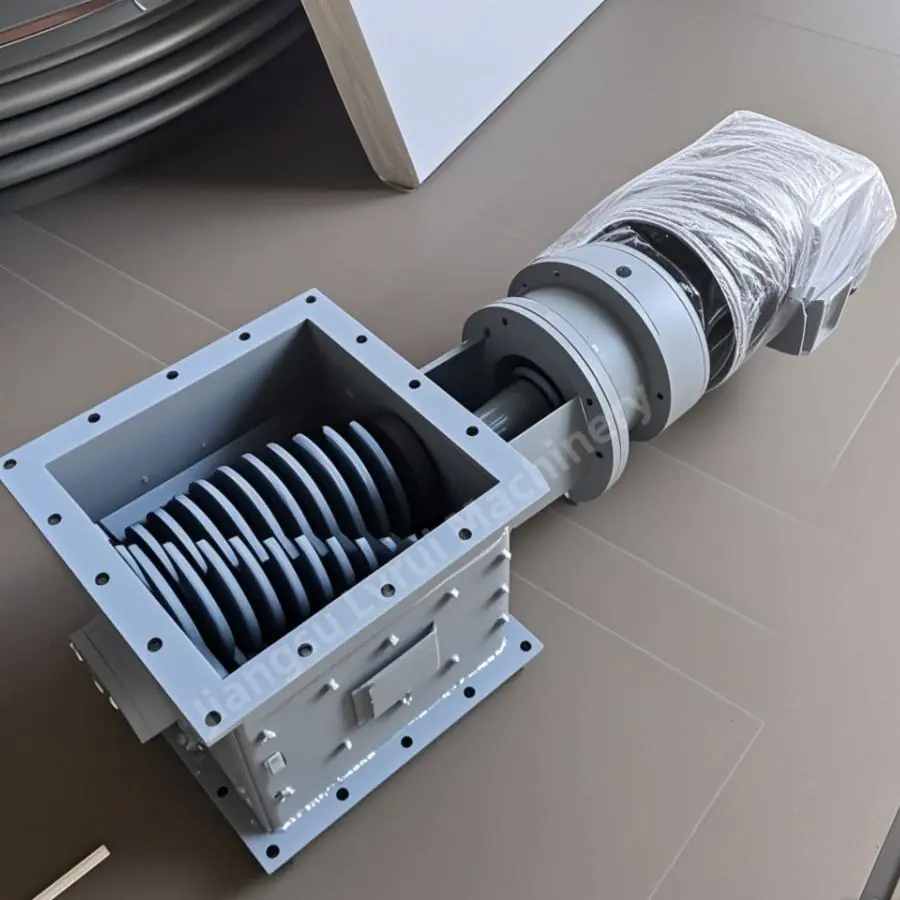

Industrial Lump Breaker for Cement & Bulk Material Handling

(Pemecah Gumpalan untuk Bubuk & Material Curah)

High-Torque bulk material lump breaking system for Agglomerate Crushing & Smooth Material Flow

Overview

Lump breakers are industrial de-agglomeration devices designed to gently reduce oversized lumps in bulk materials and restore free-flowing conditions.

By breaking compacted agglomerates without generating excessive fines, lump breakers help stabilize material flow, protect downstream equipment, and improve overall process reliability in cement and bulk powder handling systems.

Lump Breaker for Cement Plants & Silo Discharge Systems

In cement plants, lump formation often occurs due to moisture, long storage time, and material compaction inside silos. These agglomerates can cause bridging, unstable discharge, and inconsistent feeding during conveying operations.

A properly selected cement lump breaker addresses these challenges by restoring uniform particle flow, reducing unplanned downtime, and ensuring stable cement discharge under continuous operating conditions.

Features

✅ Crushes hard lumps into small particles

✅ Prevents silo bridging and chute blockage

✅ High-strength rotor blades

✅ Low noise, low dust generation

✅ Easy cleaning and simple maintenance

✅ Customizable shaft speed and capacity

✅ Suitable for abrasive and bulk solid materials

Reference: Learn more about bulk material size reduction principles from the Bulk Online technical resource.

Working Principle

Material enters the breaker chamber where rotating blades crush the lumps and shear agglomerated powder. The crushed material discharges as free-flowing, uniform particles, allowing downstream equipment such as conveyors, mixers, and feeders to operate smoothly.

Technical Specifications

| Model | Capacity (t/h) | Feed Size (mm) | Output Size (mm) | Power (kW) |

|---|---|---|---|---|

| LRB400 | 100 | ≤300 | ≤30 | 4-5.5 |

| LRB500 | 200 | ≤400 | ≤30 | 5.5–7.5 |

| LRB600 | 250 | ≤500 | ≤30 | 7.5–18.5 |

*Can be customized according to material hardness, humidity and installation space.

Advantages

✅ Improves material flow & feeding stability

✅ Reduces downtime caused by blockages

✅ Compact structure & low energy consumption

✅ Low dust & low noise operation

✅ Long service life & heavy-duty components

✅ Ideal as pre-crusher before conveying, mixing, or pneumatic systems

For upstream conveying solutions, see our Air Slide Conveyor Systems.

Applications

✅ Cement & concrete powder handling

✅ Fly ash, gypsum, and lime processing

✅ Chemical and fertilizer granules

✅ Mining and mineral bulk solids

✅ Under-silo and hopper discharge points

✅ Upstream of pneumatic and mechanical conveying lines

FAQs About Lump Breaker

What is a lump breaking unit used for?

A lump breaking unit is used to break agglomerated or compacted bulk materials into smaller, free-flowing particles. It helps prevent blockages and ensures smooth downstream conveying and processing.

Where is this equipment installed in cement plants?

In cement plants, this equipment is typically installed at material transfer points such as under silos, hoppers, or before conveying equipment, where agglomerated material needs to be conditioned before further processing.

What materials can a lump breaker handle?

This deagglomeration equipment is suitable for cement, fly ash, gypsum, lime, chemical powders, fertilizer granules, and other bulk solids prone to agglomeration.

What is the difference between a lump breaker and a crusher?

A bulk material lump breaker gently breaks agglomerates without generating excessive fines, while crushers are designed for aggressive size reduction of hard materials.

Can lump breakers be customized?

Yes. LVRUI lump breaking systems can be customized based on material properties, capacity requirements, and installation space.

Why is a lump breaker important for cement silo discharge?

During silo discharge, cement is prone to agglomeration caused by moisture and compaction. A lump breaker ensures consistent discharge behavior by eliminating compacted lumps, reducing blockages, and improving the reliability of downstream conveying systems.

Ready to Get a Reliable Lump Breaker Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours.

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects