Mesin Pengisian Curah Semen vs Batu Kapur: Perbedaan & Panduan Pemilihan

Introduction (EN)

In bulk material handling systems, selecting the right loading equipment is crucial for efficiency, dust control, and long-term operational stability. Cement Bulk Loaders and Limestone Bulk Loaders may appear similar, but they are designed to handle materials with very different physical properties, flow behaviors, and environmental requirements. This guide provides a clear comparison of their structure, performance, and application scenarios, helping plant operators and engineers choose the most suitable solution for their specific production needs.

Pengantar (ID)

Dalam sistem penanganan material curah, pemilihan mesin pengisian yang tepat sangat berpengaruh terhadap efisiensi kerja, pengendalian debu, dan stabilitas operasional jangka panjang. Meskipun Cement Bulk Loader dan Limestone Bulk Loader terlihat serupa, keduanya dirancang untuk menangani karakteristik material yang berbeda, mulai dari sifat aliran hingga kebutuhan lingkungan kerja. Panduan ini akan membahas perbedaan utama keduanya serta membantu operator pabrik menentukan solusi terbaik sesuai kebutuhan produksi.

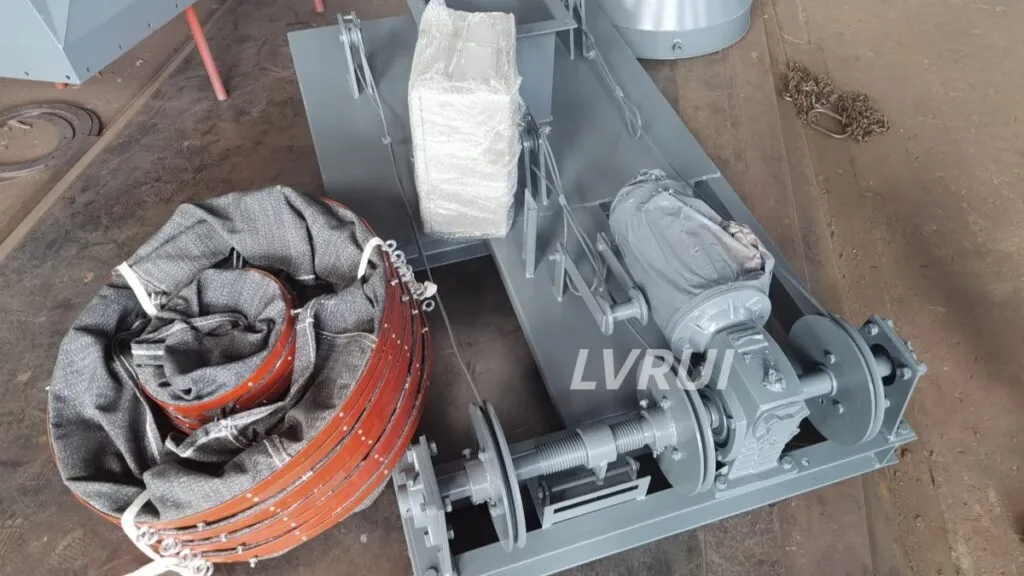

1. What is a Cement Bulk Loader?

A Cement Bulk Loader is designed to transfer powdered cement into bulk trucks in a controlled and dust-free manner. It features telescopic loading pipes, dust collectors, and airflow management systems to prevent environmental pollution.

Key Features:

✓ Telescopic loading spout

✓ Integrated dust extraction

✓ Wear-resistant inner lining

✓ High sealing performance

✓ Supports FCV Gate (Cement Silo) connection

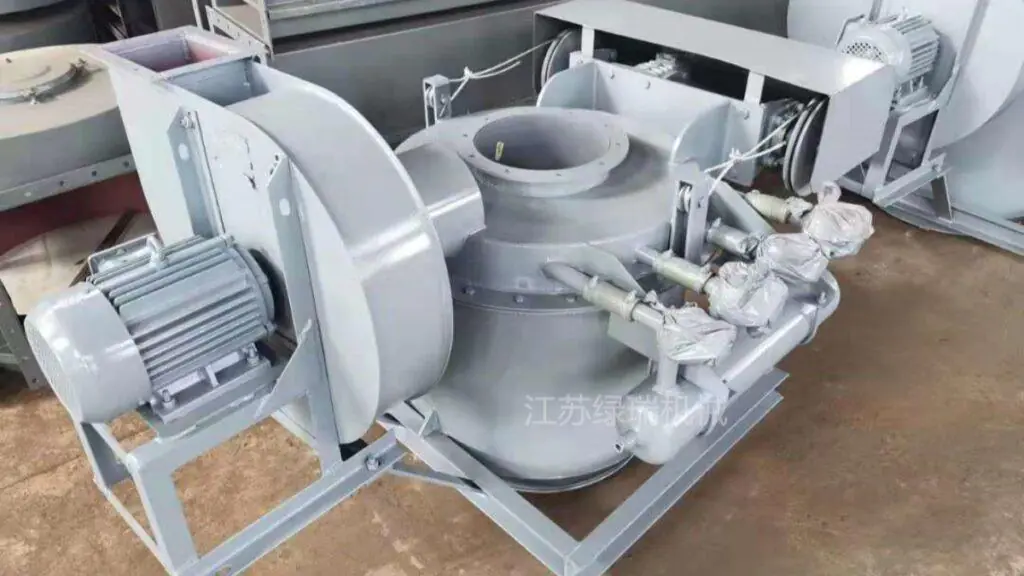

2. What is a Limestone Bulk Loader?

Limestone Bulk Loader handles coarse limestone particles or fine powder from storage silos to transport vehicles. Compared with cement, limestone has higher abrasion and density.

Key Features:

✓ Heavy-duty body structure

✓ Anti-abrasion lining

✓ Larger material flow channel

✓ Compatible with FCV Gate (Fly Ash Silo)

3. Cement Bulk Loader vs Limestone Bulk Loader – Key Differences

| Feature | Cement Bulk Loader | Limestone Bulk Loader |

|---|---|---|

| Material Type | Fine powder cement | Crushed limestone or granular |

| Dust Control | High requirement | Medium requirement |

| Wear Resistance | Moderate | High |

| Discharge Speed | Controlled flow | Higher flow rate |

| FCV Gate Matching | FCV Gate (Cement Silo) | FCV Gate (Fly Ash Silo) |

| Filter System | Precision filter | Standard filter |

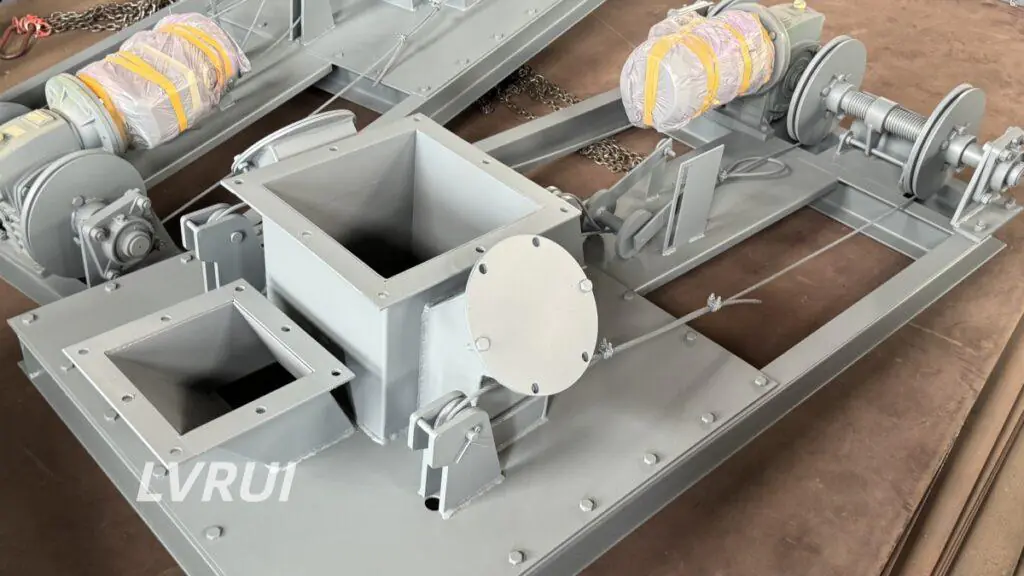

4. How FCV Gate Enhances System Performance

FCV Gate (Cement Silo)

Controls cement powder discharge to avoid bridging and uneven flow, ensuring smooth feeding into the bulk loader system.

FCV Gate (Fly Ash Silo)

Optimizes granular material flow from fly ash silos and limestone storage tanks, improving overall delivery consistency.

5. Selection Guide – How to Choose?

Choose Cement Bulk Loader if:

✓ Handling fine cement powder

✓ Strict dust control required

✓ High precision loading needed

Choose Limestone Bulk Loader if:

✓ Handling coarse or heavy materials

✓ High abrasive resistance required

✓ Faster discharge needed

Common Applications

• Cement plants

• Limestone mills

• Fly ash silos

• Bulk transport stations

• Ready-mix concrete plants

• Power plant discharge systems

Benefits of Professional Bulk Loading Systems

✓ Dust-free environment

✓ Reduced material loss

✓ Improved loading speed

✓ Longer equipment lifespan

✓ Seamless connection with FCV Gate systems

✓ Better compliance with environmental standards

Indonesian Summary – Versi Bahasa Indonesia

Perbandingan ini membantu pengguna memilih loader curah yang sesuai berdasarkan jenis material. Cement Bulk Loader lebih cocok untuk bubuk halus seperti semen, sementara Limestone Bulk Loader ideal untuk material kasar seperti batu kapur. Kombinasi dengan FCV Gate memastikan aliran stabil dan efisien.

Keunggulan:

✓ Pengisian bersih tanpa debu

✓ Kontrol aliran stabil

✓ Struktur tahan aus

✓ Efisiensi tinggi

📞 CONTACT SECTION

Contact Our Engineering Team

Email: info@lvrui-conveyor.com

WhatsApp: +86 18261998937