(EN)Smart Automation for Accurate Flow Regulation in Cement & Powder Handling Systems

(ID ) Otomatisasi Cerdas untuk Pengaturan Aliran Akurat pada Sistem Penanganan Semen & Material Curah

Introduction

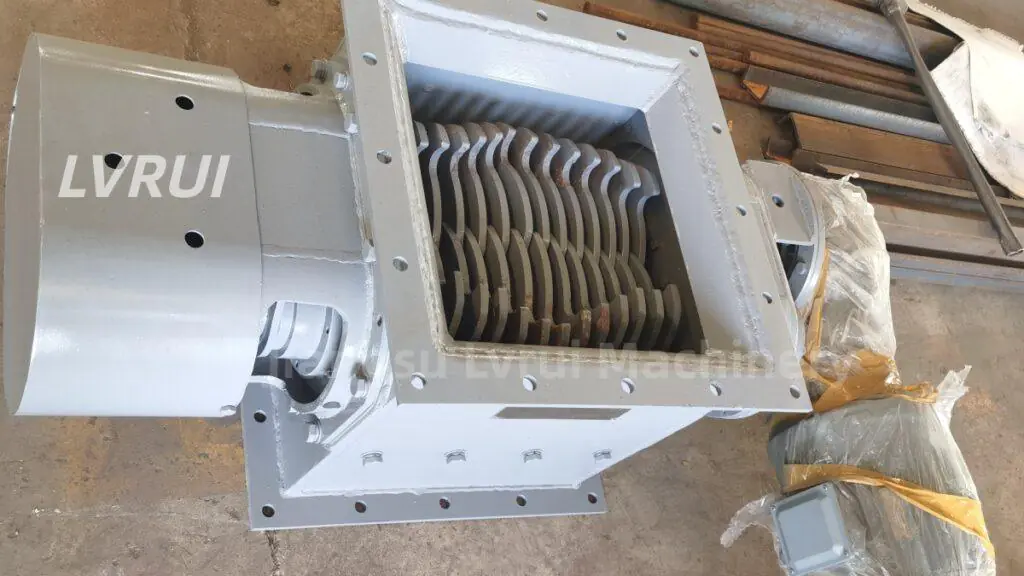

Motorized Flow Control Gate Valve is a key automated component designed to precisely regulate the flow of bulk materials such as cement, fly ash, limestone powder, clinker, and other fine aggregates in industrial conveying systems. By integrating an electric actuator with a heavy-duty slide gate mechanism, this valve ensures stable material discharge, reduced manual intervention, and improved operational efficiency.

This type of valve is widely applied in cement plants, silo discharge systems, pneumatic conveying lines, and bulk loading stations where consistent flow control and automation are critical for productivity and safety.

What is a Motorized Flow Control Gate Valve?

A Motorized Flow Control Gate Valve is an electrically driven slide gate device that controls the opening and closing of bulk material flow through hoppers, silos, conveyors, and pipeline systems. The motorized actuator replaces manual or pneumatic control, allowing remote operation and precise flow adjustment.

It supports automatic process control through PLC systems, enabling accurate flow regulation based on production demand.

Key Functions

√ Accurate flow regulation for fine powders and granular materials

√ Automated opening and closing via electric motor

√ Remote control integration with PLC system

√ Prevents material blockage and overfeeding

√ Enhances production efficiency and system stability

Structure & Working Principle

The Motorized Flow Control Gate Valve consists of:

• Heavy-duty steel housing

• Sliding gate plate

• Electric motor actuator

• Limit switch control system

• Sealing ring & dust-proof structure

• Mounting flange

Working Process: When activated, the electric motor drives the slide plate to move horizontally, adjusting the opening size to regulate material flow rate. The system can operate in automatic or manual mode depending on process requirements.

Applications in Industrial Systems

Motorized Flow Control Gate Valves are commonly used in:

• Cement silo discharge systems

• Fly ash storage and unloading systems

• Limestone powder processing lines

• Pneumatic conveying systems

• Belt conveyor discharge points

• Bulk material loading & unloading stations

Advantages of Motorized Flow Control Gate Valve

√ High control precision

√ Stable material discharge rate

√ Reduced labor dependency

√ Longer service life

√ Improved automation level

√ Lower maintenance cost

Motorized vs Pneumatic Flow Control Gate Valve

| Feature | Motorized Type | Pneumatic Type |

|---|---|---|

| Control Method | Electric Motor | Air Pressure |

| Precision | High | Medium |

| Automation | Excellent | Good |

| Energy Source | Electricity | Compressed Air |

| Maintenance | Low | Medium |

How to Choose the Right Motorized Flow Control Gate Valve

Consider the following factors:

• Type of material (cement, fly ash, limestone)

• Flow rate requirement

• Installation position

• Operating environment (dust level, humidity)

• Automation level required

• System integration compatibility

A properly selected valve ensures smooth operation and minimizes downtime.

Integration with Bulk Material Handling Systems

Motorized Flow Control Gate Valve works seamlessly with:

√ Cement Bulk Loader

√ Telescopic Loading Chute

√ Air Slide Conveyor

√ Bucket Elevator

√ Dust Collector System

√ Pneumatic Conveying System

Together, these components form a complete intelligent bulk material handling solution.

Why Choose LVRUI Motorized Flow Control Gate Valve?

• High-quality industrial-grade materials

• Precision-engineered design

• Customizable actuator options

• Reliable performance for heavy-duty environments

• Proven application in global cement plants

📞 Contact Our Engineering Team

Looking for a reliable Motorized Flow Control Gate Valve solution?

Email: info@lvrui-conveyor.com

WhatsApp: +86 18261998937

✓ Free technical consultation

✓ Custom design solutions

✓ Global export support

We are ready to support your next project.