(EN)Durable Rod Gate for Precise Material Regulation in Industrial Applications

(ID)Gerbang Batang yang Tahan Lama untuk Pengaturan Material yang Akurat dalam Aplikasi Industri

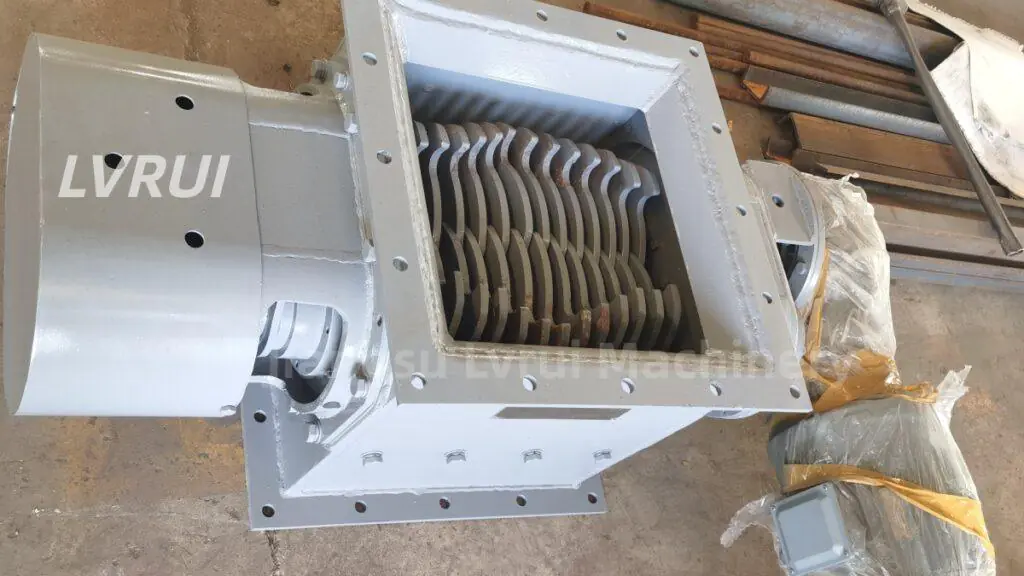

In bulk material handling industries such as cement, mining, lime, fly ash, and chemical powder processing, controlling the material flow at the silo or hopper outlet is critical. A Rod Gate, also known as a Silo Rod Gate, Hopper Rod Gate, or Manual Rod Slide Gate, is one of the most reliable flow-control devices designed for silo and hopper discharge points.

This article gives you a complete guide to what a Rod Gate is, how it works, applications, benefits, technical options, and how to choose the right Rod Gate for your silo or hopper system.

What Is a Rod Gate?

A Rod Gate is a manual or motor-operated flow-control device installed at the silo or hopper outlet to regulate, start, or stop the discharge of bulk solid materials.

Common names:

- Rod gate for silo discharge

- Rod gate for hopper discharge

- Manual rod slide gate

- Silo discharge gate

- Hopper outlet gate valve

- Bulk material slide gate

- Powder discharge rod gate

- Cement silo rod gate

- Industrial rod gate valve

Rod gates are commonly used for powder, granules, and fine particles, such as cement, fly ash, lime powder, gypsum, grains, sand, coal dust, and minerals.

How Does a Rod Gate Work?

A Rod Gate operates through a horizontal movement of a sliding blade driven by steel rods or a mechanical lever.

When the handle is pulled or rotated, the rod transmits motion to the sliding plate, allowing precise opening and closing.

Key Features:

- Simple and durable design

- Smooth opening and closing

- Suitable for abrasive materials

- Low maintenance

- Cost-effective for silo and hopper discharge systems

Applications of Rod Gate for Silo and Hopper Discharge

Rod Gates are widely used in:

- Cement plants & packing systems

- Fly ash handling systems

- Lime powder and mineral processing

- Grain silos and agricultural storage

- Building material plants

- Chemical and powder manufacturing

- Mining & quarry operations

- Bulk truck or railcar loading

- Rod gate for cement silo

- Rod gate for powder material discharge

- Rod gate for fly ash silo outlet

- Slide gate for bulk material flow control

- Hopper discharge control gate

Benefits of Using a Rod Gate

1. Precise Flow Control

Allows variable opening positions for controlling material flow rate.

2. Strong & Durable for Harsh Materials

Handles abrasive and dry bulk materials without deformation.

3. Low Maintenance

Few moving parts → long lifespan with minimal lubrication.

4. Cost-Effective

Compared with pneumatic or motorized slide gates, rod gates are significantly more economical.

5. Easy Installation

Standard flanged design fits silo outlets, hoppers, bins, chutes, and conveyors.

Rod Gate Design Options

To meet different industrial applications, rod gates are available in different material and structural options:

Material Options

- Carbon steel (Q235 / Q345)

- Stainless steel 304 / 316

- Anti-corrosion coating options

Available Sizes

- 300 × 300 mm

- 400 × 400 mm

- 500 × 500 mm

- 600 × 600 mm

- Custom sizes available

Operation Types

- Manual rod operation

- Motorized rod gate

- Chain wheel operated

- Lever-operated rod gate

- Stainless steel rod gate

- Custom size rod gate for silo

- Manual rod slide gate valve

- Heavy-duty rod gate for powder handling

How to Choose the Right Rod Gate for Your Silo or Hopper?

When selecting a Rod Gate, consider:

1. Material Type

Fine powder → stainless steel

Abrasive minerals → carbon steel + wear-resistant liner

2. Silo / hopper outlet size

Match outlet dimensions to ensure sealing and flow stability.

3. Operating frequency

Frequent operations → reinforced structure

Low-frequency use → standard design is enough

4. Installation position

Horizontal / inclined / connected to screw conveyor

5. Environmental conditions

High humidity, corrosive materials, or outdoor installations may require stainless steel or anti-corrosion coating.

Why Choose Lvrui Machinery Rod Gate?

Lvrui Machinery provides industrial-grade Rod Gates designed for long service life and stable flow control for multiple industries.

Our Rod Gates Features:

- Heavy-duty steel construction

- High sealing performance

- Smooth operation with minimal manual force

- Customization for materials, sizes, and flange types

- Suitable for cement, lime, fly ash, minerals, chemicals, grains, etc.

Lvrui’s rod gates are widely used in silo discharge systems, hopper outlets, belt conveyors, screw feeders, and dust-free loading systems.

📞 Contact Us for Silo & Hopper Rod Gate Solutions

Whether you need a standard rod gate or a fully customized discharge gate, Lvrui Machinery can provide complete solutions for powder and granular materials.

👉 Email: info@lvrui-conveyor.com

👉 Website: lvrui-conveyor.com

👉 Request a quote anytime!