(EN)Robust Industrial Lump Breaker for Cement, Mining, Chemical & Bulk Solids

(ID)Pemecah Gumpalan Industri untuk Semen, Pertambangan, Kimia & Material Curah

Introduction

Bulk solids — whether cement, fly ash, limestone, fertilizer, chemical powders, salts, or mineral ores — often tend to form agglomerates or lumps during storage, transport, or humidity exposure. These lumps cause flow problems, blockages, and inefficiencies. That’s why a robust industrial lump breaker is essential: it ensures smooth discharge, consistent flowability, and protects downstream equipment in screw conveyors, pneumatic conveying lines, hoppers, silos, and feeders.

Explore more bulk-material handling equipment and full solution sets at:👉 https://lvrui-conveyor.com/

What Is a Lump Breaker & Why You Need One

An industrial lump breaker (also known as a lump crusher, delumper, or de-agglomerator) is a mechanical device designed to break down large clumps or agglomerates of bulk solids into smaller, free-flowing particles — without overgrinding or generating excessive fines. powderprocess.net+2permixmixers.com+2

When dry powders and granules are stored for a long time (in silos, big-bags, railcars, etc.), they may compact or cake due to moisture or pressure. Lumps can form and cause severe issues: blocked feeders, uneven feeding, inconsistent mixing, or even damage to downstream equipment. A lump breaker restores material flowability and prevents these operational problems. palamaticprocess.com+1

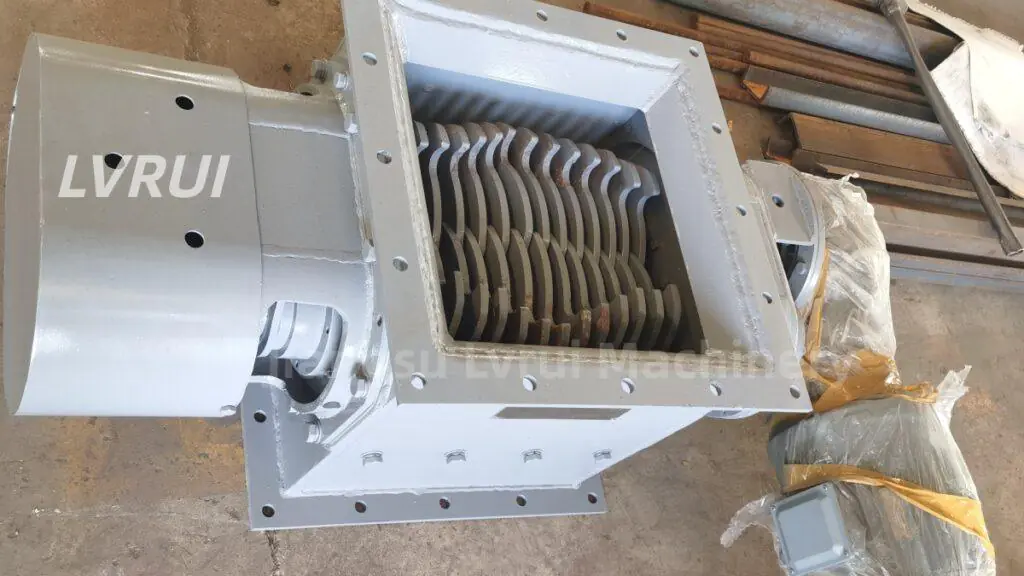

Key Features of LVRUI Lump Breaker

- ✅ Heavy-Duty Construction — built with robust carbon steel or abrasion-resistant materials for long service life in harsh environments. stedman-machine.com+1

- ✅ Low-Speed, High-Torque Crushing — gentle yet effective breaking action that avoids overgrinding, heat buildup, or excessive fines. powderprocess.net+1

- ✅ Multiple Configuration Options — single-shaft, dual-shaft, twin-rotor, or custom designs; rectangular, square, or inline housings; optional mesh/grating for sizing output. palamaticprocess.com+1

- ✅ Wide Material Compatibility — suitable for cement, clinker dust, fly ash, limestone, fertilizer, salts, chemicals, minerals, food powders, sugar, salts, coal, chemicals, gypsum, and more. Munson Machinery+2Powder Bulk Solids+2

- ✅ Improved Downstream Flow & Processing — ensures uniform particle flow, prevents bridging/blockage, protects feeders, conveyors, rotary valves, mills, and packing lines. franklinmiller.com+1

Applications Across Industries

Industrial lump breakers from LVRUI are widely used in:

- Cement & Building Materials — to break up clinker dust, cement lumps, gypsum, lime etc.

- Mining & Minerals — ore lumps, coal, mineral fines, filter cakes.

- Chemical & Fertilizer — powders, salts, fertilizers, chemical granules, hygroscopic materials.

- Food & Agriculture — sugar, salt, grains, feed, flour, spices, salts.

- General Bulk Handling & Conveying Systems — silos, hoppers, big-bags, pneumatic conveying lines, rotary valves, feeders, packing plants. wamgroup.com+2Jersey Crusher+2

Benefits of Using a Lump Breaker Before Conveying or Processing

- ✔ Prevents blockages and bridging in silos/hoppers — ensures continuous flow. palamaticprocess.com+1

- ✔ Protects downstream equipment (screw conveyors, rotary valves, mills) from damage due to large lumps — reduces maintenance and downtime. franklinmiller.com+1

- ✔ Improves throughput and processing efficiency — materials flow smoothly and consistently, lowering risk of clogs and production interruptions. Sterling Systems & Controls+1

- ✔ Ensures uniform particle distribution — critical for mixing, blending, packing, and chemical reactions. powderprocess.net+1

- ✔ Versatile across a wide range of materials — from dry powders to sticky or hygroscopic materials. Munson Machinery+1

How Lump Breakers Work (Working Principle)

Most lump breakers consist of a rotor and a stator comb (or fixed grid). As the rotor turns, its pins or blades pass through the fixed comb, crushing lumps between rotor and stator. The final particle size depends on the clearance between pins/blades and comb, or on mesh size when an outlet grid is used. powderprocess.net+1

Designs may vary:

- Single-shaft with comb — simple, compact, cost-effective

- Dual-shaft / twin-rotor — higher throughput, better for heavy-duty applications

- Inline or hopper-mounted — flexible for retrofit into existing lines

- Optional mesh outlet — ensures controlled particle size distribution

Conclusion

For reliable bulk material handling and free-flowing discharge from silos, hoppers, or conveyors — trust LVRUI’s industrial lump breaker. With customizable designs, heavy-duty construction, and proven performance, we help cement plants, mining operations, chemical facilities, and bulk powder systems worldwide maintain efficiency and avoid production downtime.

Proper installation of a lump breaker for cement silos significantly improves system reliability and reduces operational downtime.

Need a robust lump breaker tailored to your material and flow requirements?

Contact LVRUI for engineering support, custom configuration, and fast delivery.

📩 Email: info@lvrui-conveyor.com

🌐 Website: https://lvrui-conveyor.com/

Ringkasan Produk: Lump Breaker Industri

Lump breaker industri adalah mesin mekanis yang dirancang untuk memecah gumpalan atau aglomerat pada material curah seperti semen, fly ash, kapur, bahan kimia, pupuk, serbuk mineral, gula, garam, dan lain-lain. Mesin ini mengembalikan material ke ukuran partikel bebas-gumpal, sehingga aliran material menjadi mulus — mencegah sumbatan pada silo, hopper, conveyor, atau saluran pneumatik.

Keunggulan Utama

- Struktur baja tugas berat, tahan aus dan korosi

- Pemecahan lembut dengan torsi tinggi, tanpa menghasilkan terlalu banyak fines

- Konfigurasi fleksibel: single-shaft, dual-shaft, inline atau hopper

- Cocok untuk semen, mineral, bahan kimia, pupuk, gula, garam, plastik, dll.

- Meningkatkan aliran material, mencegah bridging, melindungi peralatan downstream

Aplikasi

- Discharge silo & hopper

- Sistem pneumatik conveying / pneumatic conveying

- Pabrik semen / klinker / gypsum / pupuk / bahan kimia

- Industri pertambangan, agrikultur, farmasi, makanan ringan