(EN) A Complete Guide to Telescopic Loading Chutes for Dust-Free Bulk Material Loading

(ID) Panduan Lengkap Tentang Telescopic Loading Chute untuk Pemuatan Material Curah Bebas Debu

Introduction

A Telescopic Loading Chute is a dust-free bulk loading system used for transferring materials such as cement, fly ash, grain, clinker, minerals, and powders into trucks, ships, railcars, or silos. It ensures clean, efficient loading while preventing material spillage and dust pollution(Wikipedia Dust ).

In this guide, you’ll learn how a telescopic loading chute works, the components involved, and how to choose the right type for your facility.

What Is a Telescopic Loading Chute?

A Telescopic Loading Chute is a vertically extendable loading system designed to discharge powdered or granular materials safely into a container. Its key purpose is to achieve dust-free loading—especially when used together with systems like the Air Slide Conveyor .

How a Telescopic Loading Chute Works (Working Principle)

1. Material Feeding

Material enters the chute from a silo or conveyor.

2. Chute Extension

The chute lowers automatically using lifting ropes or chains until it reaches the target loading point.

3. Dust Collection System

Built-in dust filters extract airborne dust and send it back to the chute, ensuring zero pollution.

4. Controlled Material Flow

Internal cones guide material smoothly—material flow can also be regulated using equipment such as Diverter Valve to stabilize distribution.

5. Retraction

After loading, the chute retracts automatically for the next batch.

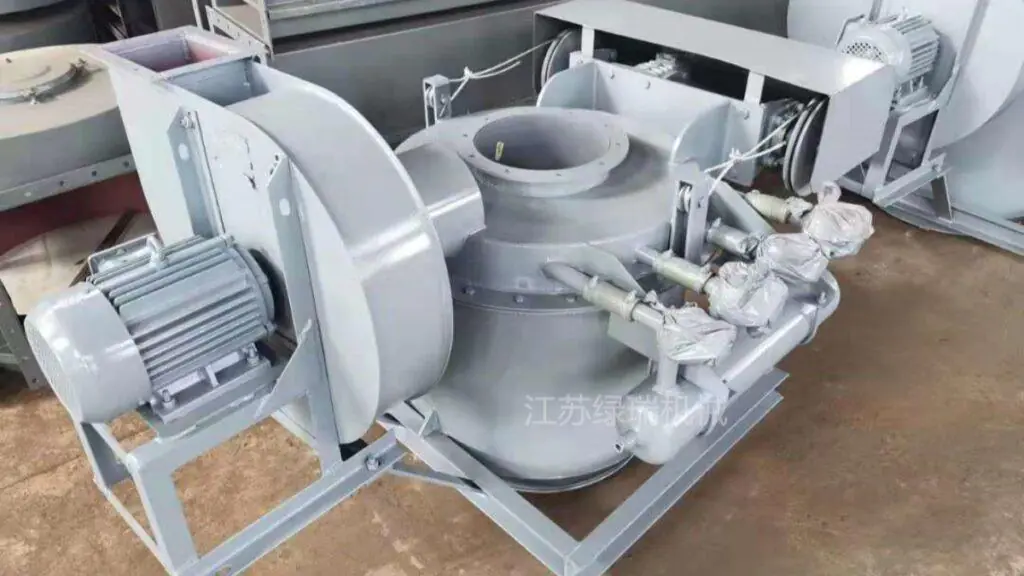

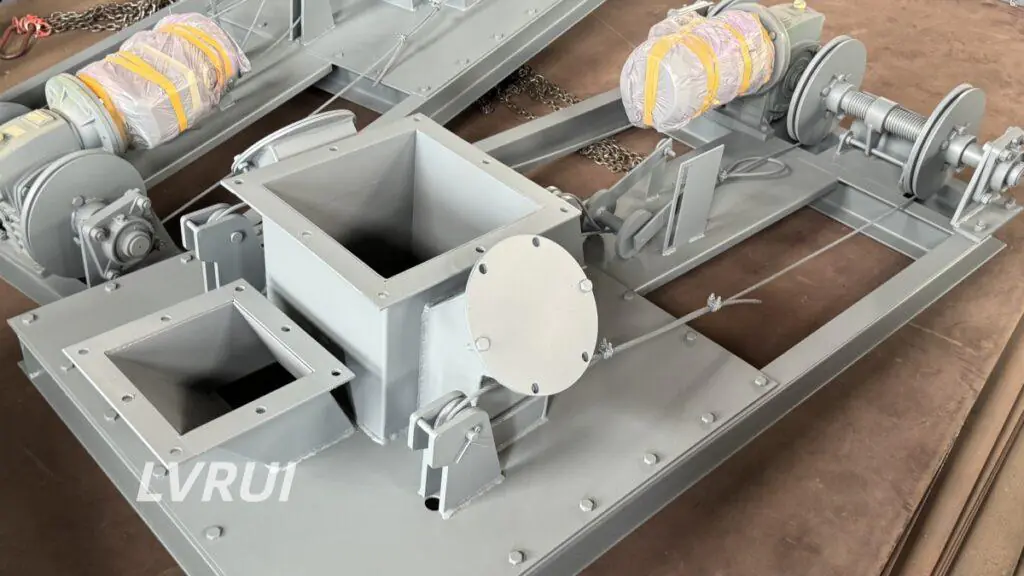

Key Components of a Telescopic Loading Chute

- Upper casing

- Internal feeding cone

- Telescopic tubes

- Dust extraction system

- Lifting winch / actuator

- Position sensors

- Loading spout

- Level detection sensors

Applications of Telescopic Loading Chutes

Telescopic loading chutes are widely used in:

- Cement plants

- Fly ash loading systems

- Grain handling facilities

- Mining and minerals

- Chemical powder handling

- Silo truck loading

- Ship loading stations

These systems are essential in modern bulk material handling operations.

How to Choose the Right Telescopic Loading Chute

When selecting a chute, consider these factors:

✔ Material type

Powder, granular, abrasive, sticky, ultrafine.

✔ Loading height

Truck, trailer, railcar, or ship.

✔ Dust control requirements

External dust collector or integrated dust filter.

✔ Flow capacity

Match chute size with silo discharge rate.

✔ Automation options

Manual, semi-automatic, or fully automatic with sensors.

For further safety guidelines, refer to OSHA’s dust-control recommendations.

Conclusion

The Telescopic Loading Chute is a crucial component for dust-free, efficient, and environmentally safe loading of bulk powders. With proper design, automation, and material compatibility, it can significantly improve productivity and system reliability.

Need a custom loading solution? Contact LVRUI Engineering Team Today for a technical consultation and quote.

Apa itu Telescopic Loading Chute?

Telescopic Loading Chute adalah peralatan pemuatan material curah yang dirancang untuk memuat semen, fly ash, biji-bijian, dan bubuk industri secara bersih tanpa debu. Sistem ini bekerja dengan memperpanjang cerobong, mengontrol aliran material, dan mengurangi polusi debu. Cocok untuk pabrik semen, silo penyimpanan, dan fasilitas bongkar muat curah lainnya.