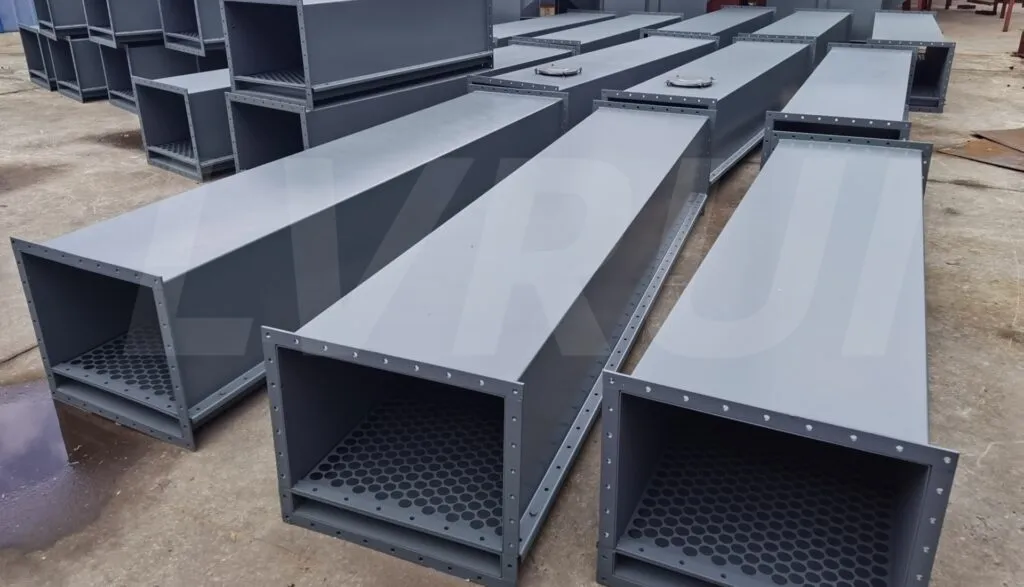

(EN)Integrated Aeration Pad and Air Slide Conveyor Solution for Stable Powder Discharge and Conveying

(ID)Solusi Terintegrasi Aeration Pad dan Air Slide Conveyor untuk Aliran Bubuk yang Stabil dan Efisien

Why Combine Aeration Pads with Air Slide Conveyors?

Aeration pad air slide conveyor systems are widely used to ensure stable powder discharge and continuous conveying in cement and bulk material handling plants.

In many bulk material handling systems, flow problems rarely come from the conveyor itself, but from poor material discharge at silos and hoppers.

This is where aeration pads play a critical role.

- Aeration pads fluidize powder at the silo cone or hopper outlet

- Air slide conveyors rely on a stable, fluidized material layer

- Together, they create continuous, gravity-assisted powder flow

👉 This integrated design is widely used in cement plants, fly ash terminals, and powder storage systems.

How Aeration Pads Improve Air Slide Conveyor Performance

Step-by-step working principle:

- Aeration pads are installed at the silo cone or hopper bottom

- Low-pressure air passes through the aeration fabric

- Powder material becomes fluidized and behaves like liquid

- Material flows evenly into the Air Slide Conveyor inlet

- The air slide conveyor transports material smoothly to the next process

This combination significantly reduces:

- Material bridging

- Rat-holing

- Uneven discharge

- Conveyor overload

Typical Application Layout (Engineering Practice)

A common layout in cement plants:

- Cement silo bottom → Aeration pads

- Discharge chute → Air slide conveyor

- Transfer point → Flow control gate or diverter

- Downstream → Packing machine or bulk loader

This system ensures stable feeding, especially for fine powders like cement, fly ash, and limestone.

👉 Learn more about Air Slide Conveyor working principles on our product page.

Industries Using Aeration Pad + Air Slide Conveyor Systems

This integrated solution is widely applied in:

- Cement production plants

- Fly ash handling systems

- Lime powder storage

- Bulk powder loading systems

- Pneumatic conveying feed zones

Compared with mechanical feeders, this solution offers:

- Lower energy consumption

- Fewer moving parts

- Reduced maintenance

- Better dust control

Aeration Pad vs Mechanical Discharge Devices

Why engineers prefer aeration pads before air slide conveyors:

- No rotating components

- Uniform air distribution

- Gentle material handling

- Longer service life

For fine powders, aeration pad + air slide conveyor systems are often more reliable than screw feeders or rotary valves.

Design Tips for Optimal System Performance

When designing this combined system, engineers should consider:

- Aeration fabric permeability

- Air pressure and airflow control

- Silo cone angle

- Air slide conveyor slope

- Material characteristics (particle size, moisture)

📌 Proper engineering design ensures stable flow without over-aeration.

🔗 For powder fluidization theory

FAQs – Aeration Pad + Air Slide Conveyor Systems

Q1: Can aeration pads be used without air slide conveyors?

A: Yes, aeration pads can improve material flow on their own, but combining them with air slide conveyors provides a more stable and continuous conveying solution for fine powders.

Q2: Are aeration pads suitable for all bulk materials?

A: Aeration pads work best with fine, dry powders such as cement, fly ash, and limestone. Coarse or wet materials may require different discharge solutions.

Q3: How many aeration pads are needed for one silo?

A: The number depends on silo diameter, cone angle, and material flow behavior. Engineering calculation is recommended for optimal layout.

Ready to Get a Reliable Aeration Pad & Air Slide Conveyor Solution?

Partner with LVRUI for professional bulk material handling solutions and responsive technical support.

✅ Get expert quotation and customized solution within 12 hours

✅ Factory direct supply with strict quality control

✅ Professional engineering support from experienced team

✅ Stable delivery for overseas industrial projects

Contact LVRUI today to get your customized aeration pad and air slide conveyor system.

📧 Email: info@lvrui-conveyor.com

📱 WhatsApp: +86 18261998937

🌐 Website: https://lvrui-conveyor.com

Indonesian Short Version

Sistem Aeration Pad + Air Slide Conveyor banyak digunakan dalam industri semen dan penanganan bubuk untuk memastikan aliran material yang stabil dan bebas penyumbatan.

Aeration pad membantu mencairkan bubuk di bagian bawah silo, sementara air slide conveyor memindahkan material secara halus dengan konsumsi energi rendah.

Solusi ini sangat cocok untuk semen, abu terbang, dan bubuk halus lainnya.