(EN)Top 7 Common Problems Caused by Lumps in Bulk Materials

(ID)7 Masalah Umum Akibat Gumpalan Material Curah (Dan Solusi Lump Breaker)

Why Lumps Form in Bulk Materials

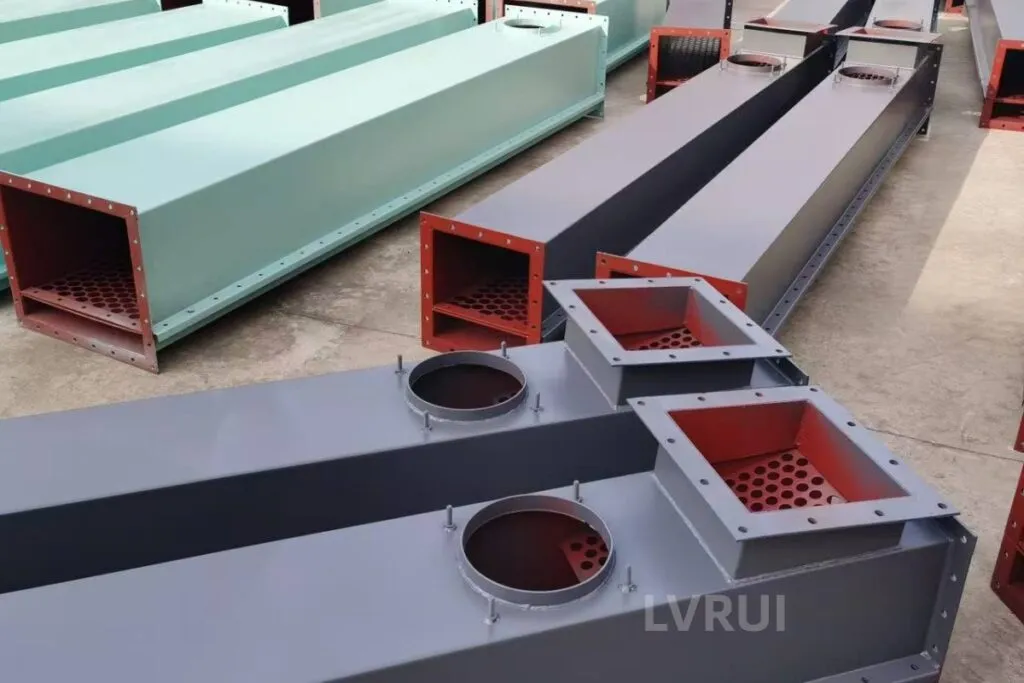

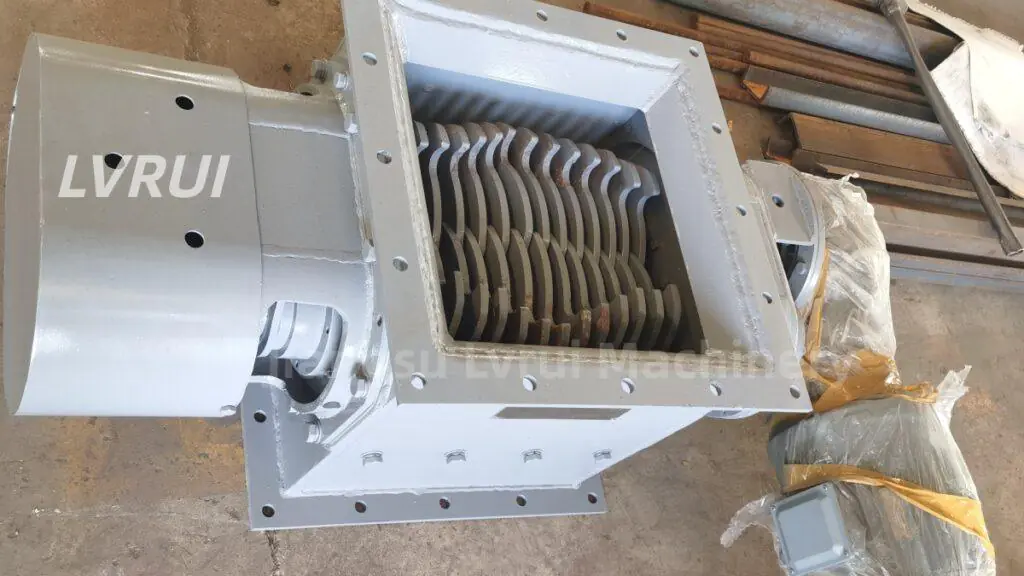

Lump breakers play a critical role in solving problems caused by lumps and agglomerates in bulk materials, which are often underestimated in industries such as cement, mining, and chemical processing.

In modern cement plants, a lump breaker for cement silos plays a critical role in preventing material blockage and ensuring stable discharge flow.

Bulk material lumping usually occurs due to:

- Moisture absorption

- Material aging or caking during storage

- High compaction pressure

- Temperature fluctuations

- Improper material handling

These issues are common in materials such as cement clinker, limestone, gypsum, coal, fly ash, fertilizer, sugar, and chemical powders.

In many cement and powder handling systems, installing a lump breaking equipment before downstream conveying equipment is an effective way to prevent material blockages and flow interruptions.

👉 Learn more about industrial lump breaker solutions for cement and powder handling.

Top 7 Problems Caused by Lumps in Bulk Materials

1️⃣ Blockage in Chutes and Hoppers

Large lumps can easily block feed chutes, discharge hoppers, and transfer points, interrupting material flow.

How Lump Breakers Help:

A lump breaking system crushes oversized material before it reaches downstream equipment, ensuring smooth discharge.

2️⃣ Conveyor Belt Damage

When large lumps fall onto belt conveyors, they can cause:

- Belt tears

- Impact damage

- Misalignment

Solution:

Installing a lump disintegrator upstream of belt conveyors reduces impact load and extends belt life.

3️⃣ Uneven Feeding to Process Equipment

Lumps cause inconsistent feeding to:

- Crushers

- Mills

- Air slide conveyors

- Screw conveyors

This leads to unstable production output.

How Lump Disintegrator Help:

They reduce material to a controlled, uniform particle size, ensuring consistent flow.

4️⃣ Reduced Efficiency of Air Slide Conveyors

Air slide conveyors rely heavily on fine, free-flowing powder. When large lumps enter the system, airflow distribution becomes uneven, significantly reducing conveying efficiency.

This is why proper lump size control is critical for air gravity conveying systems, especially in cement plants.

👉 Related reading: how air slide conveyors work based on the air gravity principle

5️⃣ Increased Wear on Downstream Equipment

Oversized lumps accelerate wear on:

- Valves

- Rotary feeders

- Diverter valves

- Screw flights

How Lump Crusher Help:

By crushing lumps early, wear is minimized across the entire conveying system.

6️⃣ Dust and Safety Hazards

Manual lump breaking increases:

- Dust exposure

- Injury risks

- Safety incidents

👉 According to OSHA guidelines on industrial material handling safety, uncontrolled manual lump breaking can increase dust exposure and workplace injury risks.

7️⃣ Unexpected Production Downtime

Blockages caused by lumps often lead to unplanned shutdowns, maintenance delays, and production losses.

Solution:

A properly selected industrial lump breaker ensures continuous and stable operation.

🔧 How Lump Breakers Solve These Problems

Lump breakers are designed to:

- Break agglomerates without grinding material too fine

- Handle moist and sticky materials

- Operate continuously with low maintenance

Key Benefits

✅ Prevent blockages

✅ Improve material flow consistency

✅ Protect downstream equipment

✅ Reduce manual labor

✅ Enhance system safety

Typical Applications of Lump Breakers

Lump breakers are widely used in:

- Cement plants

- Power plants

- Mining and mineral processing

- Chemical and fertilizer industries

- Food and sugar processing

How to Select the Right Lump Breaker

When selecting a powder lump breaking, consider:

- Material type and hardness

- Moisture content

- Required throughput

- Installation position

- Desired output particle size

For a broader understanding of material flow behavior, conveying methods, and system design principles, you can also refer to the general overview of bulk material handling fundamentals.

FAQS About Lump Breaker

Q1: Is a Lump Crusher the same as a crusher?

No. Lump breakers are designed to gently reduce agglomerates, not crush material aggressively.

Q2: Can industrial lump breaking solution handle sticky materials?

Yes, industrial lump crusher is suitable for moist and sticky bulk materials.

Q3: Where should a Lump Reducer be installed?

Typically under silos, hoppers, or before conveyors and feeders.

📞 Need a Reliable Lump Breaker for Your Bulk Material System?

Looking for a durable lump breaker for cement, powder, or granular material handling?

LVRUI provides industrial-grade lump breakers designed to prevent blockages, protect equipment, and improve system efficiency.

📧 Email: info@lvrui-conveyor.com

🌐 Website: https://lvrui-conveyor.com/

Versi Singkat Bahasa Indonesia

Gumpalan pada material curah sering menyebabkan penyumbatan, aliran material tidak stabil, serta kerusakan pada conveyor dan peralatan proses. Masalah ini umum terjadi pada industri semen, pertambangan, pembangkit listrik, dan industri kimia.

Penggunaan lump breaker industri membantu menghancurkan gumpalan material sebelum masuk ke peralatan berikutnya, sehingga aliran material menjadi lebih lancar, aman, dan efisien. Lump breaker sangat efektif untuk material seperti semen, batu kapur, gypsum, batubara, dan bubuk kimia.

📞 Butuh Lump Breaker yang Andal untuk Sistem Material Curah Anda?

LVRUI menyediakan lump breaker industri berkualitas tinggi untuk aplikasi semen, bubuk, dan material granular, dirancang untuk mencegah penyumbatan dan meningkatkan keandalan sistem.

📧 Email: info@lvrui-conveyor.com

🌐 Website: https://lvrui-conveyor.com/