(EN)Ensuring Smooth Material Flow with Aeration Pads, Fluidization Plates, and Air Slide Systems

(ID)Memastikan Aliran Material yang Lancar dengan Aeration Pad, Pelat Fluidisasi, dan Sistem Air Slide

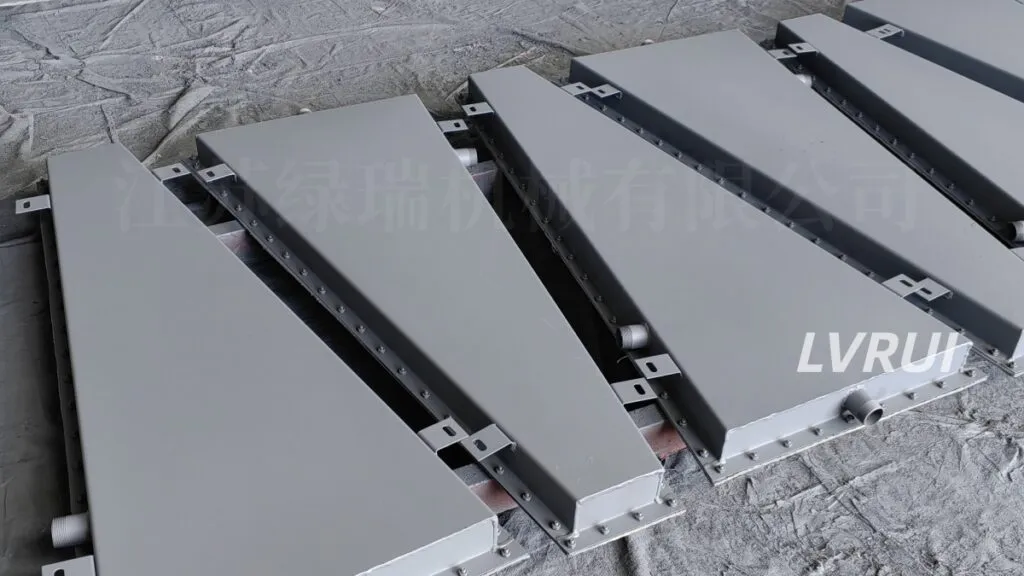

Air Slide Aeration Plate technology plays a vital role in maintaining smooth powder flow inside cement plants, fly ash systems, and bulk material handling facilities. These aeration components—also known as aeration pads, aeration panels, aeration boxes, and fluidization pads—ensure stable, reliable discharge and prevent powder bridging or blockage inside silos and hoppers.

Efficient powder flow is essential in industries handling cement, lime, gypsum, fly ash, alumina, and other fine materials. Without aeration, powders often compact, arch, or become stagnant. This is why air slide systems and aeration plates are widely used to stabilize and fluidize bulk materials.

These aeration components are essential in systems such as:

- Air slide conveyors

- Silo discharge fluidization

- Hopper aeration

- Powder flow-aid equipment

- Cement homogenizing systems

What Are Air Slide Aeration Plates?

Air slide aeration plates consist of a steel housing and an air-permeable fabric allowing compressed air to fluidize cement, fly ash, or lime.

This turns powder into a liquid-like state, ensuring smooth flow.

Global naming variations include:

- Air slide conveyor aeration plate

- Aeration pad / aeration panel

- Aeration box

- Fluidization pad / fluidizing plate

- Air permeable plate

- Powder flow aid aeration panel

How Aeration Pads Improve Flow

✔ 1. Prevent bridging and material buildup

Aeration breaks powder compaction and ensures smooth discharge.

✔ 2. Enables low-energy conveying

Air slide conveyors move cement long distances using minimal power.

Use aeration plates together with air slide conveyors for best performance:

✔ 3. Stabilizes silo discharge

Uniform airflow eliminates material arching and blockage.

✔ 4. Ideal for feeders, packers & bulk loaders

Consistent flow ensures efficiency in downstream equipment.

For bulk loading solutions, check our cement bulk loader systems:

✔ 5. Works with all powder materials

Cement, fly ash, gypsum, lime, alumina, and other fine powders.

Applications in Industrial Plants

- Cement air slide conveyor systems

- Cement silo discharge aeration

- Fly ash fluidization systems

- Powder discharge cone aeration

- Homogenizing / blending silos

- Powder flow aid systems

See also our Air Slide Fabric / Canvas used with these systems:

Why Choose LVRUI Aeration Plates?

- Heavy-duty welded steel structure

- High-permeability air slide canvas

- Consistent airflow & stable fluidization

- Low maintenance & long lifespan

- OEM sizes & installation customization

- Compatible with all global cement plant standards

Learn more about cement flow systems from the Portland Cement Association:

Conclusion

Whether handling cement, fly ash, lime, or industrial powders, air slide aeration plates are vital for ensuring stable, energy-efficient, and continuous material flow.

LVRUI’s aeration plates, aeration pads, and fluidization panels provide reliable support for modern cement and industrial plants worldwide.

📞 Contact LVRUI for a Custom Air Slide Aeration Plate Solution

LVRUI provides professional air slide aeration plates, aeration pads, fluidization panels, and powder flow-aid solutions for cement plants, fly ash systems, mining industries, and bulk material handling applications.

📩 Email: info@lvrui-conveyor.com

🌐 Website: https://lvrui-conveyor.com/

📞 Contact us for a free quotation and technical support anytime.