(EN)A Complete Guide for Selecting Industrial Flow Control Gates in Powder & Bulk Conveying Systems

(ID)Panduan Lengkap Memilih Flow Control Gate untuk Sistem Penanganan Material Curah

Introduction — Why Flow Control Gates Matter

Flow Control Gates play a critical role in bulk material handling, ensuring accurate feeding, flow regulation, and safe discharge of powders such as cement, clinker, lime, fly ash, gypsum, grain, and minerals.

Selecting the wrong gate can lead to:

- Material leakage

- Unstable flow

- System blockage

- Higher maintenance

- Reduced operational efficiency

This guide will help you choose the correct Flow Control Gate for your plant and application.

Types of Flow Control Gates (Which One Do You Need?)

Motorized Flow Control Gate

Best for high-precision regulation, especially in cement plants and automated bulk material lines.

✔ Fine control

✔ Adjustable opening

✔ Good for continuous production

🔗 Motorized Flow Control Gate – LVRUI

Pneumatic Flow Control Gate

Ideal for fast switching, high-frequency operations, and systems requiring immediate response.

✔ Quick action

✔ Lower cost

✔ Simple automation

✔ Good for fly ash, grain, powders

🔗 Pneumatic Flow Control Gate – LVRUI

Manual Flow Control Gate

Best for low-frequency regulation or systems without automation.

✔ Low cost

✔ Simple maintenance

✔ Suitable for non-critical flow control

Key Factors When Selecting a Flow Control Gate

Material Type & Characteristics

Different materials have different flow behaviors.

Consider:

- Powder fineness

- Moisture content

- Abrasiveness

- Temperature

Highly abrasive materials (clinker, minerals) require wear-resistant liners.

📘 External reference:https://en.wikipedia.org/wiki/Bulk_material_handling

Required Flow Accuracy

Choose motorized gates for precise feeding control.

Choose pneumatic gates for bulk open/close operations.

Actuation Method

| Actuator Type | Advantages | Applications |

|---|---|---|

| Motorized | Precise flow control | Cement plants, batching systems |

| Pneumatic | Fast response | Fly ash, powder conveying |

| Hydraulic | High force | Heavy-duty or sticky material |

| Manual | Basic control | Low-use systems |

Sealing System(Zero Leakage Is Critical)

Key criteria:

- Dust-tight sealing

- Anti-wear design

- Proper gasket material

- Smooth contact surfaces

🔗 Butterfly Damper Valve – Dust Control

Installation Space & Mounting Position

Check:

- Silo outlet size

- Conveyor connection flanges

- Vertical vs horizontal installation

- Actuator clearance

Safety & Dust Control Requirements

Flow Control Gates must comply with industrial safety guidelines.

📘 External references:

• OSHA Dust Control Guidelines

https://www.osha.gov/dust

• CEMA Standards for Bulk Handling

https://www.cemanet.org/

Flow Control Gate Applications

✔ Cement silo discharge

✔ Clinker & limestone feeding

✔ Fly ash conveying systems

✔ Mining & minerals processing

✔ Chemical powders

✔ Grain & fertilizer loading

✔ Truck/bulk unloading systems

Common Mistakes to Avoid

❌ Choosing the wrong actuator

❌ Ignoring material abrasiveness

❌ Overlooking sealing and dust control

❌ Not checking installation dimensions

❌ Using non-industrial-grade gates

❌ Ignoring maintenance access space

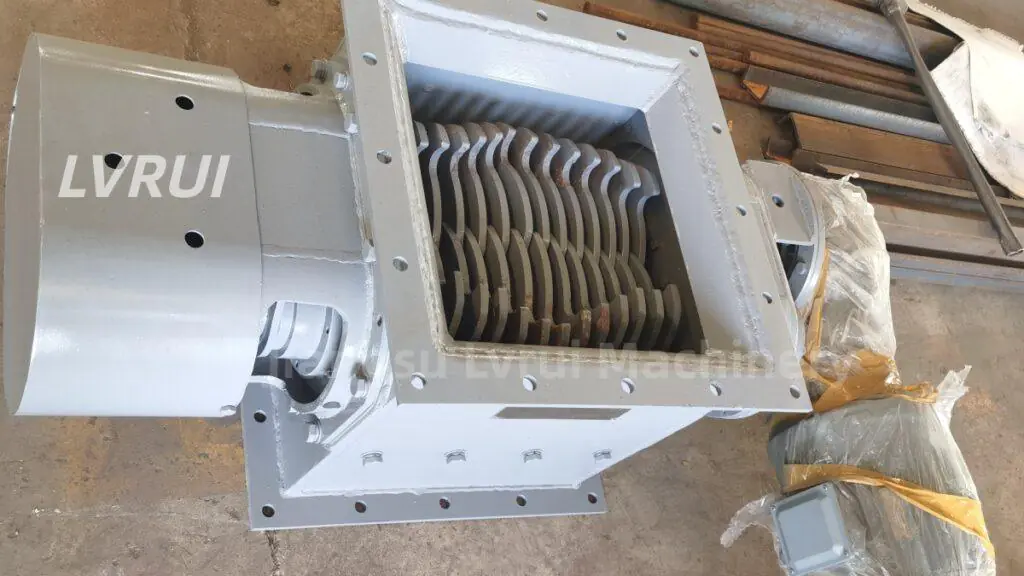

LVRUI Flow Control Gates — Why Customers Choose Us

LVRUI designs Flow Control Gates specifically for cement plants, fly ash systems, mining, and powder conveying lines.

Our gates feature:

✔ Heavy-duty steel structure

✔ Wear-resistant liners

✔ Motorized/pneumatic customization

✔ Zero-leakage sealing

✔ Long-duty-cycle actuators

✔ 100% factory testing before shipment

Conclusion

Selecting the right Flow Control Gate ensures reliable feeding, stable material flow, reduced downtime, and improved plant efficiency.

If you’re unsure which type fits your project, LVRUI provides free engineering consultation based on your material and application.

Looking for a reliable Flow Control Gate for your bulk material handling system?

Contact LVRUI for customized motorized/pneumatic Flow Control Gates.

📧 Email:lrst88@126.com

🌐 Website:https://lvrui-conveyor.com

🇮🇩 Indonesian Short Version

Panduan Memilih Flow Control Gate yang Tepat untuk Material Curah

Flow Control Gate digunakan untuk mengatur aliran material seperti semen, fly ash, clinker, dan bubuk industri lainnya.

Untuk memilih gate yang tepat, perhatikan jenis material, tingkat akurasi aliran, metode aktuator (motorized/pneumatic), sistem sealing, serta kebutuhan ruang instalasi.

LVRUI menyediakan Flow Control Gate industri dengan desain heavy-duty, zero leakage, dan opsi aktuator sesuai kebutuhan.

Mencari Flow Control Gate yang andal untuk sistem material curah Anda?

Hubungi LVRUI untuk solusi gate motorized/pneumatic yang disesuaikan.

📧 Email:info@lvrui-conveyor.com

🌐 Situs:https://lvrui-conveyor.com