A Flow Control Valve is an essential component in bulk material handling systems, especially in cement plants, mining industries, chemical processing lines, and powder conveying applications. It is mainly used to adjust, regulate, and stop the flow of dry bulk materials such as cement, clinker, fly ash, limestone powder, gypsum, and other granular or powder products.

This article provides a complete guide to help you understand the structure, working principle, advantages, and selection factors for industrial flow control valves.

1. What Is a Flow Control Valve?

A flow control valve is an industrial device designed to regulate, adjust, and stop the flow of dry bulk materials such as cement, fly ash, clinker, and limestone powder. It is typically installed beneath silos, hoppers, or conveying systems to ensure stable, controllable, and uniform material discharge.

Unlike shut-off valves, flow control valves allow precise flow adjustment, making them essential for automated bulk material handling systems in cement plants and powder processing industries.

It is commonly used in:

- Cement manufacturing

- Bulk powder conveying systems

- Chemical and mineral production

- Metallurgy and mining

- Dry mortar and construction materials

- Pneumatic conveying pipelines

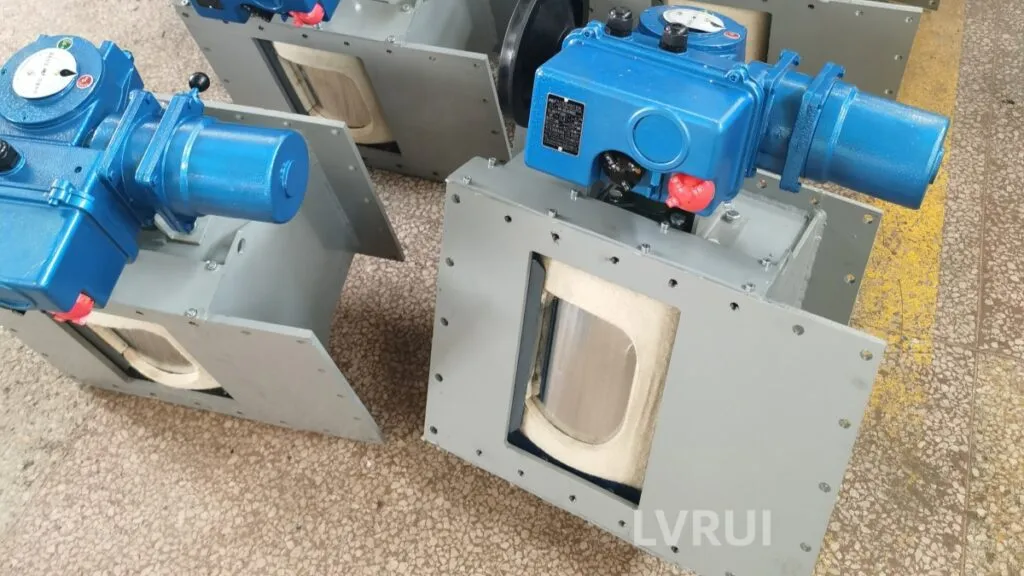

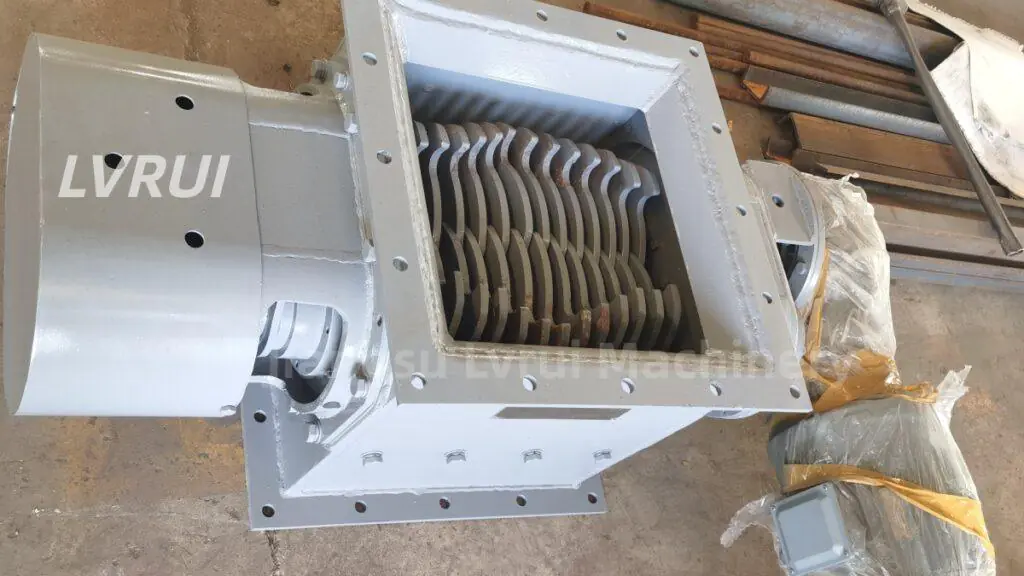

2. Structure of a Flow Control Valve

A standard industrial flow control valve typically includes:

✔ Valve Body – heavy-duty welded structure for long-term stability

✔ Adjustable Gate Plate / Butterfly Plate – controls the material opening

✔ Actuator (Manual, Electric, or Pneumatic) – power source to open/close

✔ Sealing Components – prevent material leakage

✔ Flow Indicator or Position Sensor (optional)

Common types include:

- Manual Flow Control Valve

- Electric Flow Control Valve

- Pneumatic Flow Control Valve

- Motorized Rotary Flow Control Valve

3. Working Principle

The valve controls material flow by adjusting the opening angle or opening height of the internal plate.

When the actuator moves:

- Opening increases → Material flow increases

- Opening decreases → Material flow slows down

- Fully closed → Material completely stops

For powder materials like cement or fly ash, the valve ensures a uniform and stable discharge, preventing clogging and surging.

Pneumatic and electric actuators allow:

- Remote control

- Precise flow regulation

- Integration with PLC or automation systems

In modern cement plants, flow control valves function as critical control nodes within bulk material handling systems. They stabilize material flow between storage silos, conveyors, and downstream processing equipment.

By maintaining consistent discharge rates, these valves prevent material arching, reduce dust leakage, and ensure smooth integration with automated control systems such as PLC-based process lines.

Learn more about bulk material handling principles .

4. Key Benefits of Flow Control Valves

1. Precise Flow Regulation

Ensures accurate feeding and stable conveying for production lines.

2. Heavy-Duty Construction

Suitable for abrasive materials such as clinker powder or limestone.

3. Leak-proof Operation

High-quality seals prevent dust leakage and improve environmental performance.

4. Wide Compatibility

Easily installed below silos, hoppers, air slides, screw conveyors, and pneumatic pipelines.

5. Supports Automation

Electric or pneumatic actuators can integrate with modern control systems.

6. Long Service Life

Wear-resistant materials ensure long-term durability even in harsh industrial environments.

5. Applications in Cement and Powder Industries

Flow control valves are widely used in:

- Cement production lines

- Clinker grinding plants

- Bulk loading systems

- Air slide conveying systems

- Screw conveyor discharge

- Batching and weighing systems

- Chemical powder feeding

- Mineral processing

Wherever accurate material control is required, flow control valves play a vital role.

When Should a Flow Control Valve Be Used?

Flow control valves are most suitable when:

- Accurate material feeding is required

- Continuous discharge stability is critical

- Dust control is a priority

- Automated process control systems are used

They are less suitable when:

- Only simple on/off isolation is needed

- Extremely large lump materials are handled

- No precise flow regulation is required

6. How to Choose the Right Flow Control Valve?

When selecting a flow control valve, consider the following factors:

1. Material Characteristics

Granularity, moisture content, abrasiveness, corrosiveness.

2. Required Flow Capacity

Match the discharge rate and the size of the hopper or silo.

3. Control Method

- Manual

- Pneumatic

- Electric

- Hydraulic (rare, but for heavy-duty applications)

4. Valve Size & Opening Angle

Ensure compatibility with upstream/downstream equipment.

5. Sealing Type

Dust-tight design improves environmental performance.

6. Installation Environment

Temperature, humidity, and dust concentration.

7. Automation Level

Whether you need PLC integration or remote operations.

7. FAQ – Flow Control Valves in Cement Plants

What is the main purpose of a flow control valve?

The primary purpose is to regulate and stabilize the discharge flow of bulk materials, ensuring consistent feeding and preventing material blockages.

Where are flow control valves typically installed?

They are usually installed beneath silos, hoppers, air slide conveyors, and bulk material transfer points.

Why are flow control valves important in cement plants?

They prevent material arching, reduce dust leakage, improve automation control accuracy, and ensure stable production operations.

How is a flow control valve different from a shut-off valve?

A shut-off valve only stops flow, while a flow control valve allows continuous adjustment of material discharge rates.

Key Takeaway for Engineers

In bulk material handling systems, flow control valves are essential for achieving stable, adjustable, and dust-free material discharge. Their ability to regulate flow precisely makes them a critical component in cement plant automation and powder conveying processes.

Proper valve selection and maintenance directly impact operational efficiency, equipment reliability, and long-term production stability.

8. Conclusion

A Flow Control Valve is an essential device for regulating powder and bulk material flow in industrial systems. With precise adjustment, stable performance, and compatibility with automation, it plays a key role in improving production efficiency in cement plants, mineral processing, and powder handling systems.

Choosing the right flow control valve ensures reliable and dust-free material discharge, helping companies achieve smoother production, better environmental control, and lower maintenance costs.

For customized flow control valves or complete conveying solutions, feel free to contact us for professional support.