(EN)A Practical Guide for Efficient Discharge Control in Cement Silos and Bulk Material Systems

(ID)Panduan Praktis untuk Kontrol Pengeluaran yang Efisien pada Silo Semen dan Sistem Material Cura

Introduction

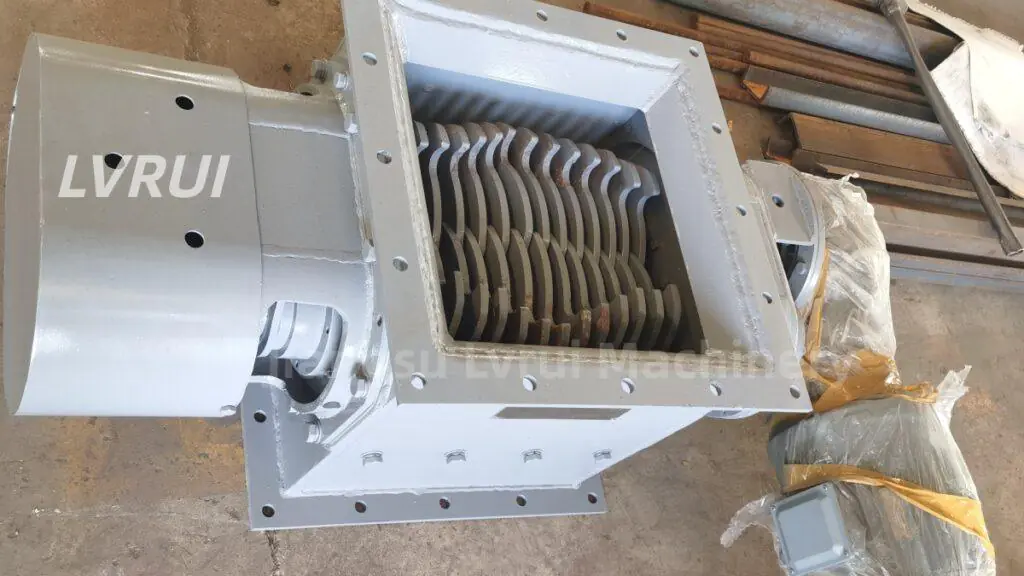

Pneumatic flow control gate Efficient control of bulk material discharge is a key factor in maintaining stable production in cement plants and industrial conveying systems. One of the most reliable solutions for this purpose is the Pneumatic Flow Control Gate, widely used under silos and hoppers for precise regulation of powder and granular materials.

This article explains how pneumatic flow control gates work, where they are commonly applied, and how to select the right model for your project.

1. Working Principle of Pneumatic Flow Control Gate

A pneumatic flow control gate operates by using compressed air to drive a cylinder that moves the gate plate horizontally. When the pneumatic cylinder extends, the slide plate opens to allow material to pass. When it retracts, the gate closes and seals the material flow.

Key characteristics of its operation include:

- Smooth and stable opening/closing movement

- Quick response time

- Accurate flow control

- Reduced dust leakage due to tight sealing structure

This mechanism ensures controlled and continuous discharge of materials, preventing sudden surges or blockages during operation.

2. Main Applications

Pneumatic flow control gates are widely used in industries handling bulk powder and granular materials, such as:

- Cement silos

- Fly ash storage systems

- Limestone powder handling

- Clinker discharge lines

- Ready-mix concrete plants

- Industrial material storage hoppers

- Pneumatic conveying systems

They are especially suitable for environments requiring frequent operation and dust-free material control.

3. Advantages in Cement Plants

In cement production, material flow stability directly affects overall efficiency. Pneumatic flow control gates offer several practical benefits:

- Reliable discharge under high load conditions

- Reduced material waste

- Improved environmental cleanliness

- Lower maintenance requirements

- Enhanced operational safety

- Stable performance in harsh industrial settings

These advantages make them a preferred solution for modern cement silo discharge systems.

4. How to Choose the Right Pneumatic Flow Control Gate

When selecting a pneumatic flow control gate, consider the following factors:

- Type of material (cement, fly ash, limestone, etc.)

- Particle size and flow characteristics

- Required discharge capacity

- Installation position (silo bottom, hopper outlet)

- Operating pressure and temperature

- Automation requirements

- Sealing performance needs

Choosing the proper size and configuration helps improve efficiency and reduces long-term maintenance costs.

5. Pneumatic vs Traditional Manual Gates

Compared with manual flow control gates, pneumatic models provide:

- More consistent flow control

- Faster response

- Less labor involvement

- Higher operational safety

- Better integration with automated systems

This makes them ideal for large-scale industrial applications where reliability and efficiency are crucial.

Conclusion

The Pneumatic Flow Control Gate plays a vital role in maintaining stable material flow within cement and bulk handling systems. With its precise control, excellent sealing performance, and low maintenance design, it significantly improves operational efficiency and environmental safety.

Selecting the right gate based on material characteristics and application requirements ensures smooth operation and long service life for your conveying system.

📞 Contact Our Engineering Team

Email: info@lvrui-conveyor.com

WhatsApp: +86 18261998937

✅ Free technical consultation

✅ Customized design available

✅ Global delivery support