In the cement industry, grain processing, chemical plants, and other bulk powder handling systems, Flap Valves play an indispensable role in controlling material flow, preventing air leakage, and maintaining system efficiency. While they may look simple, flap valves are highly reliable devices designed to handle abrasive, dusty, and granular materials under continuous operations.

In this article, we explain what a flap valve is, how it works, where it is used, and what makes it essential for modern industrial conveying systems.

✅ What Is a Flap Valve?

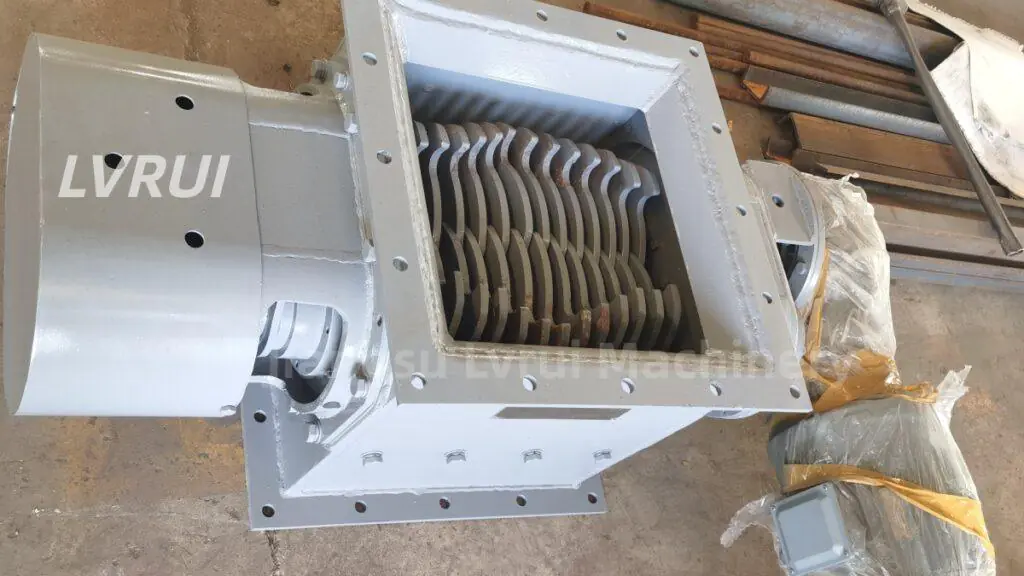

A Flap Valve (also known as a gravity flap valve or swing-type valve) is a mechanical device used to allow material to pass through a system in one direction while preventing air, dust, or gas from flowing backward. It typically consists of:

- A valve housing

- One or two hinged metal flaps

- Counterweights or pneumatic actuators

- Sealing plates or rubber seats

When material enters the valve, gravity pushes the flap open. After discharge, the flap closes tightly, sealing the pipeline and preventing air leakage.

✅ How Does a Flap Valve Work?

The operation is simple and reliable:

- Bulk powder or granules enter the flap chamber

- The weight of the material pushes the flap downward

- Product exits the valve into the next stage of conveying

- When material stops flowing, the flap naturally returns to a closed position

✅ No electricity required

✅ Low maintenance

✅ Ideal for dusty and abrasive materials

Because of these advantages, flap valves are common in pneumatic conveying and dust collection systems.

✅ Applications of Flap Valves

Flap valves are widely used in:

✅ Cement plants

✅ Fly ash and gypsum conveying

✅ Silo discharging

✅ Dust collection systems (Baghouse & cyclone)

✅ Bulk powder loading stations

✅ Chemical and food powder handling

✅ Biomass and pellet transport

In baghouse dust collectors, flap valves prevent dust from being blown back into the filter area while discharging into hoppers or screw conveyors.

✅ Advantages of Flap Valves

| Advantage | Benefit |

|---|---|

| Simple structure | Easy installation and low maintenance |

| Gravity-powered | No electrical motor needed |

| Airtight sealing | Prevents air or gas leakage |

| Wear-resistant materials | Suitable for abrasive powders |

| Handles high-temperature dust | Ideal for cement, steel, power plants |

These features make flap valves one of the most cost-effective options for gravity discharge systems.

✅ Flap Valve vs. Rotary Airlock Valve

Flap valves are often compared with rotary airlock valves. The main differences are:

| Item | Flap Valve | Rotary Airlock Valve |

|---|---|---|

| Power | No power required | Requires a motor / gearbox |

| Maintenance | Very low | Higher (bearings / rotor wear) |

| Sealing | Good | Excellent |

| Cost | Low | Higher |

| Best for | Low pressure & dust discharge | High pressure pneumatic conveying |

In many systems, flap valves are used as economic alternatives when airtight sealing is not extremely critical.

✅ How to Choose the Right Flap Valve?

When selecting a flap valve, consider:

- Material type: cement, fly ash, lime, chemicals, grains, etc.

- Temperature and abrasion level

- Valve size and opening angle

- Single-flap or double-flap design

- Seal material (carbon steel, stainless steel, rubber seat)

- Dust and air leakage requirements

A double-flap valve (double dump valve) offers better sealing performance for pneumatic systems.

✅ Why Flap Valves Improve System Efficiency

✔ Prevent air leakage

✔ Ensure continuous and stable discharge

✔ Reduce dust pollution

✔ Decrease maintenance downtime

✔ Extend filter and system life

In cement plants and bulk powder handling, even a small leakage can reduce conveying efficiency and increase energy consumption. A properly sealed flap valve keeps the system airtight and reliable.

✅ Conclusion

Flap valves are small components, but they have a big impact on the performance of bulk material handling systems. With simple design, low cost, and reliable sealing, they are widely adopted in:

- Cement & mining industries

- Dust collection systems

- Silo and hopper discharge

- Pneumatic conveying lines

Choosing the right flap valve improves overall efficiency, reduces maintenance, and helps keep your plant dust-free and reliable.