Air slide fabric—also called air slide canvas, fluidization fabric, or air permeable cloth—is a core component of air slide conveying systems used in cement, fly ash, alumina, and other powder material handling. It enables smooth, wear-free, and continuous conveying through aerodynamic fluidization.

In this article, we will explain what air slide fabric is, how it works, the available material types, key technical advantages, and where it is commonly used in bulk material handling industries.

1. What Is Air Slide Fabric?

Air slide fabric is a high-strength, air-permeable textile installed between the upper material chamber and the lower air chamber of an air slide conveyor. When compressed air passes through the fabric, powder materials become fluidized and flow easily along the sloped chute with very low friction.

Common industry names include:

- Air slide canvas

- Air slide cloth

- Fluidization fabric

- Air permeable belt

- Pneumatic conveying fabric

It is widely used for conveying cement, fly ash, alumina, lime powder, and similar dry bulk materials.

2. How Air Slide Fabric Works (Working Principle)

The working principle is simple but highly effective:

- Compressed air enters the lower chamber.

- Air passes uniformly through the air slide fabric.

- Powder material above becomes fluidized.

- Because the chute is slightly inclined (typically 6–12°), the material flows continuously by gravity.

This creates a low-energy, dust-free, and maintenance-free conveying system compared to mechanical conveyors.

3. Material Options for Air Slide Fabric

Different applications require different fabric materials. The common types include:

① Polyester Air Slide Fabric (PES)

- Most widely used

- High strength and durability

- Good heat resistance

- Excellent cost-performance ratio

- Suitable for cement and fly ash applications

② Aramid Air Slide Fabric (Nomex)

- High temperature resistance up to 250°C

- Suitable for high-temperature clinker or hot material conveying

- Superior mechanical wear resistance

③ Cotton or Blended Fabrics

- Traditional material

- Lower cost

- Used in certain low-temperature applications

4. Key Advantages of Air Slide Fabric

Air slide fabric delivers several benefits for industrial conveying:

- ✔ Uniform air permeability

- ✔ High tensile strength

- ✔ Excellent abrasion resistance

- ✔ Stable performance under continuous operation

- ✔ Long service life

- ✔ Easy replacement and installation

- ✔ Dust-free, low-maintenance operation

These advantages make it ideal for cement plants, power plants, and bulk powder terminals.

5. Common Applications

Air slide canvas is widely used across the bulk material handling system:

- Cement air slide conveyor

- Silo bottom fluidization system

- Cement packing plant feeding

- Bulk loading systems (truck and ship loaders)

- Clinker, fly ash, alumina conveying

- Blending and homogenizing systems

Any powder material requiring continuous, smooth flow can benefit from air slide fabric.

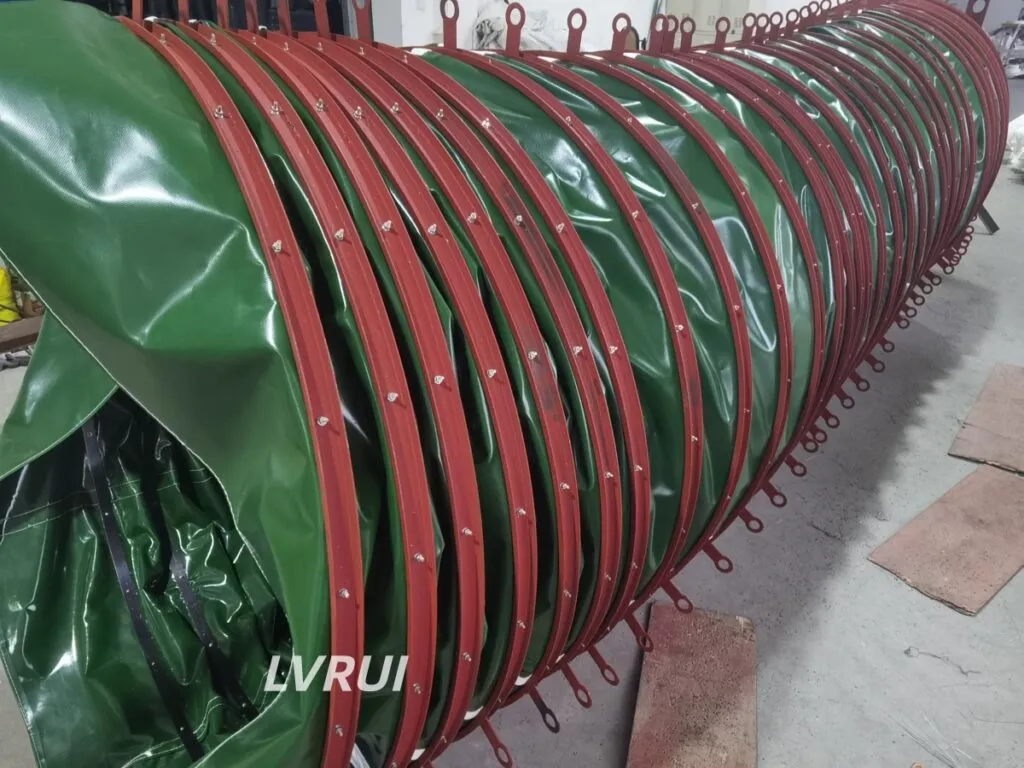

6. Why Choose LVRUI Air Slide Fabric?

LVRUI supplies high-quality air slide canvas with:

- Uniform and stable air permeability

- Strong woven structure

- High heat and abrasion resistance

- Customized width and thickness

- 100% factory price

- Fast delivery and global supply

Suitable for cement, lime, fly ash, and alumina conveying systems.

Conclusion

Air slide fabric plays a critical role in pneumatic conveying systems by enabling efficient, dust-free material flow. Choosing the right material and design ensures long service life and stable operation in demanding industrial environments.

For customized sizes, materials, or technical support, contact LVRUI Machinery for professional air slide solutions tailored to your cement or bulk material project.