(EN)A Complete Guide to Choosing the Best Diverter Valve for Powder Material Handling

(ID)Panduan Lengkap Memilih Diverter Valve Terbaik untuk Penanganan Bahan Bubuk

Introduction

Diverter Valve for Powder Materials plays a critical role in any powder conveying system. Choosing the correct type ensures stable flow distribution, zero leakage, minimal wear, and long equipment lifespan. Whether you are handling cement, fly ash, clinker dust, minerals, or grain powder, selecting the proper diverter valve is essential for efficient bulk material handling.

Choosing the right Diverter Valve for Powder Materials ensures stable flow, reduced wear, and long-term system performance.

What Is a Diverter Valve?

A Diverter Valve is a flow-direction device used to route bulk powder materials from one inlet to two or more outlets.

It is widely used in pneumatic conveying lines, gravity conveying systems, and silo discharge networks.

Learn more about powder behavior: https://en.wikipedia.org/wiki/Powder_technology

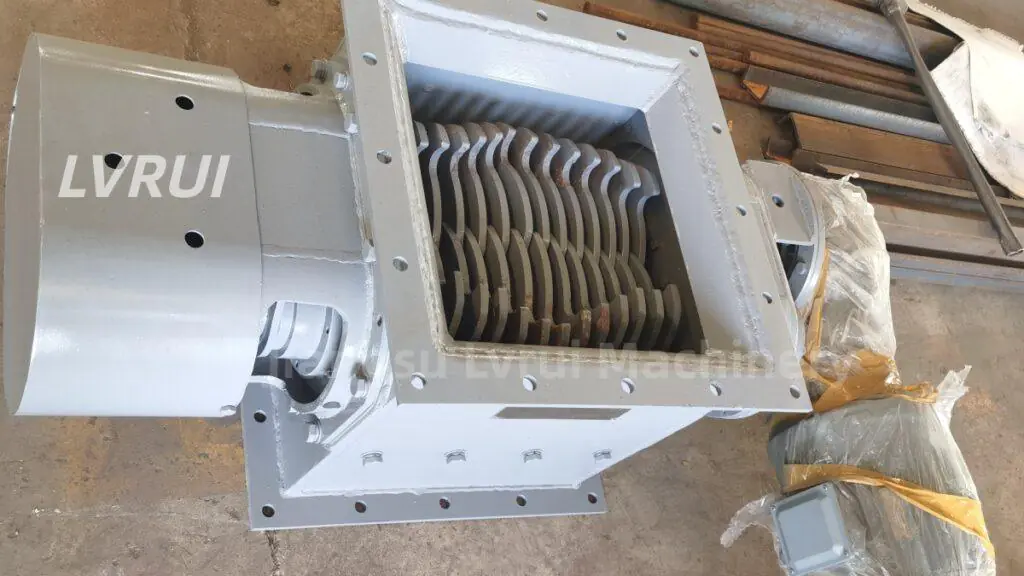

Types of Diverter Valves for Powder Handling

1. Two-Way Diverter Valve

Used to redirect materials into two different lines.

Ideal for cement plants, silo feeding, packing machines, and batching systems.

2. Three-Way Diverter Valve

Allows more routing flexibility and is used in multi-line conveying networks.

3. Gravity Diverter Valve

Best for free-flowing powders such as cement, lime, or flour.

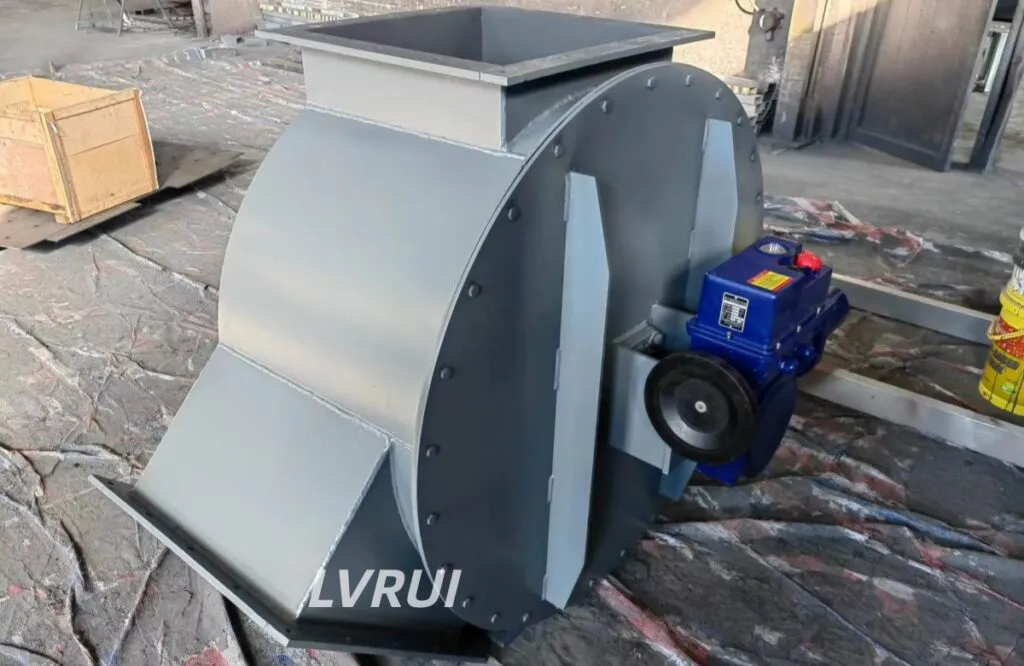

4. Pneumatic Diverter Valve

Actuated by air cylinder—recommended for fast switching and automated plants.

You can link to your relevant product category here → diverter-valve

How to Select the Right Diverter Valve for Powder Materials

1. Understand Powder Flow Characteristics

Different powders behave differently:

- ✔ Free-flowing (cement, lime, fly ash)

- ✔ Semi-abrasive (clinker dust, minerals)

- ✔ Cohesive/sticky materials (powdered chemicals)

Choosing the correct valve angle, sealing material, and outlet size depends on flow behavior.

2. Check the Operating Pressure

A diverter valve must match the system’s conveying pressure:

- Low-pressure systems → Gravity & air gravity systems

- Medium-pressure → Typical dilute-phase pneumatic systems

- High-pressure → Dense-phase conveying systems

If the pressure rating is too low, leakage or valve failure will occur.

3. Choose the Right Sealing Structure

For powder materials, sealing quality is crucial:

- ✔ Soft sealing → Best for fine powders

- ✔ Hard sealing → Best for abrasive materials

- ✔ Air-tight sealing → Prevents leakage in pressurized systems

External reference:

OSHA dust control guidelines → https://www.osha.gov/dust

4. Evaluate Wear Resistance

Abrasive materials require:

- Hardened steel

- Wear-resistant liner

- Replaceable valve gate or cone

This dramatically increases valve lifespan.

5. Consider Automation Requirements

Options include:

- ✔ Manual operated diverter valve

- ✔ Pneumatic cylinder

- ✔ Electric motorized diverter

- ✔ PLC/SCADA integration

If your plant requires fully automatic routing, choose pneumatic or motorized options.

6. Installation Space & System Layout

Check:

- Available installation height

- Piping angle & orientation

- Silo discharge position

- Accessibility for maintenance

Proper layout ensures stable operation and zero blockages.

When selecting a Diverter Valve for Powder Materials, always consider sealing performance, abrasion resistance, and conveyor layout.

Typical Applications

- Cement silo discharge

- Air slide conveying systems

- Pneumatic conveying pipelines

- Packing line powder distribution

- Fly ash handling

- Bulk material processing plants

Air Slide Conveyor 产品页面 → https://lvrui-conveyor.com/air-slide-conveyor/

For more technical explanations about bulk powder flow behavior, you can refer to:

https://en.wikipedia.org/wiki/Pneumatic_conveying

Conclusion

Choosing the right Diverter Valve for powder materials is critical for system efficiency, sealing performance, and long-term durability.

By analyzing powder type, pressure, sealing, wear resistance, and automation needs, you can ensure a reliable and stable conveying system.

Need Reliable Diverter Valve Solutions?

LVRUI provides high-performance Diverter Valve systems for cement, fly ash, clinker, grain powder, and all bulk material handling applications.

Contact us today for technical support and custom valve designs.

📩 Email: info@lvrui-conveyor.com

🌐 Website: https://lvrui-conveyor.com/

Ringkasan Bahasa Indonesia

Memilih Diverter Valve yang tepat sangat penting untuk sistem pengangkutan bahan bubuk seperti semen, fly ash, dan mineral. Faktor utama yang perlu diperhatikan meliputi karakteristik aliran bubuk, tekanan kerja, jenis seal, ketahanan aus, serta kebutuhan otomatisasi. Diverter Valve yang sesuai akan memastikan aliran material lebih stabil, tanpa kebocoran, dan meningkatkan efisiensi operasi di pabrik Anda.

Butuh Solusi Diverter Valve yang Andal?

LVRUI menyediakan sistem Diverter Valve berkinerja tinggi untuk semen, fly ash, klinker, bubuk bijian, dan berbagai aplikasi penanganan material curah lainnya.

Hubungi kami untuk dukungan teknis dan desain valve yang disesuaikan.