(EN)A Practical Comparison Guide for Bulk Material Handling, Cement Plants, and Powder Conveying Systems

(ID)Panduan Perbandingan Praktis untuk Sistem Penanganan Material Curah, Pabrik Semen, dan Transportasi Bubuk

Introduction

Butterfly damper valve vs slide gate valve is a common comparison in cement plants and bulk material handling systems, as both valves serve different flow control purposes under demanding industrial conditions.

Although both are designed for flow control, they serve very different purposes depending on material characteristics, operating conditions, and system requirements. Choosing the wrong valve often leads to leakage, material buildup, excessive wear, or poor flow control accuracy.

This guide provides a clear, engineering-based comparison to help you decide when to use a butterfly damper valve and when a slide gate valve is the better choice.

1. What Is a Butterfly Damper Valve?

A Butterfly Damper Valve is a rotary-type flow control device that uses a circular disc mounted on a shaft. By rotating the disc, the valve regulates airflow or material flow inside ducts, pipelines, or gravity-fed systems.

👉 Butterfly Damper Valve

https://lvrui-conveyor.com/butterfly-damper-valve/

Typical Characteristics

- Rotary disc structure

- Fast opening and closing

- Compact and lightweight

- Low pressure drop

- Suitable for airflow and light material regulation

Common Applications

- Pneumatic conveying systems

- Dust collection pipelines

- Cement plant air ducts

- Kiln exhaust systems

- Low-pressure powder conveying lines

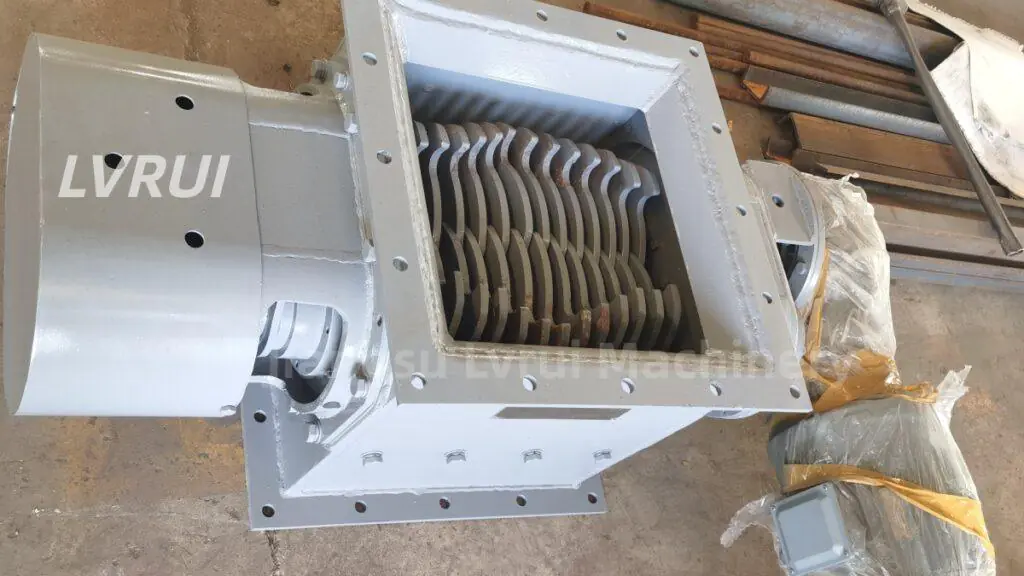

2. What Is a Slide Gate Valve?

A Slide Gate Valve (also known as a flow control gate or knife gate) uses a linear sliding plate to open or close the material passage. It is specifically designed for precise material flow regulation and complete shut-off.

Flow Control Gate / Slide Gate Valve

Typical Characteristics

- Linear sliding blade

- Excellent sealing performance

- Accurate flow control

- Designed for dry bulk solids

- Handles abrasive and heavy materials

Common Applications

- Cement and clinker discharge

- Fly ash handling systems

- Silo outlets and hoppers

- Screw conveyor inlets

- Bulk powder feeding systems

3. Butterfly Damper Valve vs Slide Gate Valve: Key Differences

| Feature | Butterfly Damper Valve | Slide Gate Valve |

|---|---|---|

| Movement type | Rotary (disc) | Linear (sliding plate) |

| Sealing ability | Moderate | Excellent |

| Flow control accuracy | Low–medium | High |

| Suitable materials | Air, light powder | Cement, fly ash, clinker |

| Shut-off function | Not fully tight | Full isolation |

| Resistance to abrasion | Limited | High |

| Installation position | Ducts, pipelines | Silos, hoppers, chutes |

4. When to Use a Butterfly Damper Valve

A butterfly damper valve is the right choice when:

- The system mainly handles air or air-material mixtures

- Precise material metering is not required

- Fast on/off operation is needed

- Installation space is limited

- Pressure drop must be minimized

Typical Use Cases

- Air balance control in cement plants

- Dust extraction systems

- Pneumatic conveying pipelines

- Ventilation and exhaust systems

Learn more about industrial dampers:

https://en.wikipedia.org/wiki/Damper_(flow)

5. When to Use a Slide Gate Valve

A slide gate valve is the better solution when:

- Handling dry bulk solids such as cement, fly ash, limestone powder

- Accurate flow regulation is required

- Complete material shut-off is necessary

- Material is abrasive or heavy

- Valve is installed under silos or hoppers

Typical Use Cases

- Silo discharge control

- Feeding bulk material into conveyors

- Batching and dosing systems

- Bulk material isolation during maintenance

➡️ External technical reference (recommended)

Insert link here:

Bulk material flow control fundamentals:

https://www.cemengal.com/en/bulk-material-handling/

6. Common Selection Mistakes (And How to Avoid Them)

❌ Using a butterfly damper valve for heavy powder discharge

✔ Use a slide gate valve instead

❌ Expecting airtight sealing from a butterfly damper

✔ Choose a slide gate valve with sealing design

❌ Installing a slide gate valve in high-speed airflow ducts

✔ Use a butterfly damper valve for airflow control

Understanding the material behavior and process requirements is key to long-term system reliability.

7. Conclusion: Which Valve Should You Choose?

There is no “better” valve—only the right valve for the right application.

- Choose a Butterfly Damper Valve for airflow control, pneumatic systems, and light material regulation

- Choose a Slide Gate Valve for accurate bulk material control, silo discharge, and abrasive materials

Making the correct choice improves system efficiency, reduces maintenance, and extends equipment lifespan.

Contact LVRUI

- Website: https://lvrui-conveyor.com

- Email: info@lvrui-conveyor.com

- Application: Cement, Fly Ash, Limestone Powder, Bulk Material Handling Systems

Butterfly Damper Valve vs Slide Gate Valve – Kapan Digunakan?

Butterfly damper valve cocok digunakan untuk pengaturan aliran udara dan sistem pneumatik, sedangkan slide gate valve lebih tepat untuk pengendalian material padat seperti semen, fly ash, dan bubuk kering.

- Butterfly Damper Valve: ringan, cepat, cocok untuk udara

- Slide Gate Valve: presisi tinggi, sealing baik, cocok untuk material berat

Pemilihan valve yang tepat akan meningkatkan efisiensi sistem dan mengurangi masalah operasional.