(EN)Common Operational Issues, Root Causes, and Practical Solutions for Air Slide Conveyor Systems

(ID)Masalah Operasional Umum, Penyebab Utama, dan Solusi Praktis pada Sistem Air Slide Conveyor

Introduction

Common problems of air slide conveyors often occur due to improper design, incorrect air pressure, unsuitable materials, or lack of maintenance. Although air slide conveyors are widely used in cement plants and bulk material handling systems, operational issues such as poor flow, dust leakage, and clogging can significantly affect conveying efficiency and system reliability.

👉 This guide focuses on real-world problems engineers face and how to fix them effectively.

🔗 What Is an Air Slide Conveyor? Complete Beginner’s Guide

1. Poor or No Material Flow

Problem

Material does not flow smoothly or stops completely inside the air slide.

Common Causes

- Insufficient air pressure

- Incorrect slope angle

- Blocked or damaged aeration fabric

Solutions

- Maintain stable air pressure within the design range

- Ensure correct installation angle (typically 6–12° depending on material)

- Inspect and replace worn aeration fabric regularly

🔗 According to CEMA, proper air distribution and slope design are critical for gravity-based powder conveying systems.

2. Excessive Dust Leakage

Problem

Dust escapes from joints, covers, or discharge points.

Common Causes

- Worn seals or poor flange connections

- Over-aeration causing fluidized powder escape

- Inadequate dust collection system

Solutions

- Improve sealing design at joints and inspection doors

- Optimize air volume rather than increasing pressure blindly

- Integrate dust collectors at discharge points

🔗 Dust control guidelines from OSHA emphasize proper enclosure and pressure control to reduce airborne dust hazards.

3. Material Build-Up or Clogging

Problem

Powder accumulates inside the air slide, leading to partial or complete blockage.

Common Causes

- Moist or hygroscopic materials

- Low-quality aeration fabric

- Contaminated compressed air

Solutions

- Ensure material moisture content is within acceptable limits

- Use high-quality, breathable aeration fabric

- Install air dryers and filters for clean air supply

🔗 Air Slide Aeration Plate for Efficient Powder Flow

4. Uneven Air Distribution

Problem

Material flows unevenly across the air slide width.

Common Causes

- Poor air chamber design

- Uneven fabric tension

- Blocked air inlets

Solutions

- Redesign air plenum for uniform pressure distribution

- Ensure correct fabric installation

- Regularly clean air supply pipelines

🔗 Basic air fluidization principles are explained on Wikipedia (search: Fluidization).

5. Reduced Conveying Capacity

Problem

Actual conveying rate is much lower than design capacity.

Common Causes

- Incorrect material properties (particle size, bulk density)

- Improper slope or air pressure settings

- System wear over time

Solutions

- Recheck material flowability and design assumptions

- Adjust air pressure and conveying angle

- Schedule routine inspection and maintenance

Frequently Asked Questions

Understanding the common problems of air slide conveyors helps engineers quickly diagnose system failures and apply the correct solutions.

Q1: Can an air slide conveyor handle wet materials?

No. Air slide conveyors are designed for dry, fine powders only. Moist materials may cause clogging and fabric damage.

Q2: What is the ideal air pressure for an air slide conveyor?

Typical operating pressure ranges from 3–10 kPa, depending on material characteristics and conveyor length.

Q3: How often should aeration fabric be replaced?

Replacement intervals vary, but regular inspection every 6–12 months is recommended in cement and fly ash applications.

Conclusion

These common problems of air slide conveyors can be effectively avoided through proper design, correct air pressure control, and regular maintenance.

Most air slide conveyor problems are caused by design mismatches, improper operation, or lack of maintenance, not by the conveying principle itself.

With correct slope design, stable air supply, and suitable aeration components, air slide conveyors can operate reliably for years with minimal energy consumption.

Need a Reliable Air Slide Conveyor for Cement & Powder Handling?

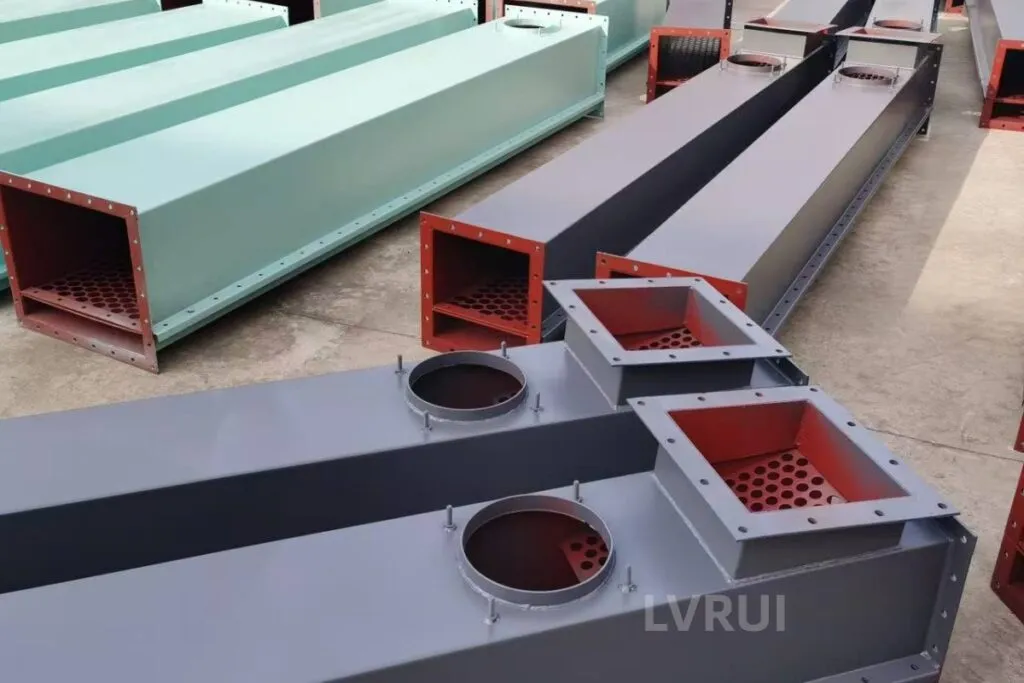

LVRUI provides custom-designed air slide conveyor systems, aeration plates, and complete dust-free powder conveying solutions for cement plants and bulk material handling industries worldwide.

Contact LVRUI today to optimize your air slide conveyor system for stable, efficient, and maintenance-free operation.

Indonesian Short Version

Air Slide Conveyor banyak digunakan di industri semen dan material curah karena hemat energi dan bebas debu. Namun, masalah seperti aliran material tidak lancar, debu berlebih, dan penyumbatan sering terjadi akibat desain atau pengoperasian yang kurang tepat. Dengan pengaturan tekanan udara yang benar, sudut pemasangan yang sesuai, serta penggunaan aeration fabric berkualitas, sistem air slide dapat bekerja stabil dan efisien dalam jangka panjang.