(EN)Engineering Guide to Choosing the Correct Damper Valve for Cement Plant Airflow Control

(ID)Panduan Teknik Memilih Damper Valve yang Tepat untuk Pengendalian Aliran Udara di Pabrik Semen

Introduction

In modern cement plants, airflow control systems play a critical role in ensuring stable kiln operation, efficient dust collection, and optimized heat exchange. At the heart of these systems lies the damper valve, a key component used in industrial airflow control systems.

Selecting the right damper valve for a cement plant is not simply a matter of size or price. It requires a deep understanding of process conditions, material characteristics, temperature, dust load, and sealing requirements. This guide provides a practical, engineering-focused approach to help you choose the most suitable damper valve for cement plant airflow control.

1. Why Damper Valve Selection Matters in Cement Plants

Cement production involves high temperatures, abrasive dust, fluctuating pressure, and continuous operation. An improperly selected damper valve can result in air leakage, increased fan energy consumption, and frequent maintenance. In accordance with requirements for industrial ventilation systems, proper airflow regulation and isolation are essential for safe and efficient plant operation.

- Air leakage and unstable airflow

- Increased fan energy consumption

- Excessive wear and frequent maintenance

- Reduced system efficiency and process control accuracy

Choosing the correct industrial damper valve improves operational stability, energy efficiency, and equipment lifespan across the entire cement production line.

2. Key Airflow Control Applications in Cement Plants

Damper valves are widely used in multiple sections of a cement plant, including:

- Kiln inlet and outlet ducts

- Preheater and pre-calciner systems

- Clinker cooler exhaust air control

- Baghouse and ESP dust collection systems

- Raw mill and cement mill ventilation

Each application presents different airflow velocities, temperatures, and dust concentrations, directly affecting damper valve selection.

In a typical cement production line, selecting the right damper valve for cement plant airflow control helps maintain stable draft conditions and improves overall system efficiency.

3. Main Types of Damper Valves Used in Cement Plants

3.1 Butterfly Damper Valve

Butterfly damper valves are commonly used for large-diameter ducts and applications requiring fast airflow regulation.

For an engineering-level comparison between airflow control and material isolation devices, you may also refer to our article Butterfly Damper Valve vs Slide Gate Valve.

Typical features:

- Simple structure and compact design

- Suitable for low to medium sealing requirements

- Cost-effective for general airflow control

Common applications:

Dust collection systems, exhaust air ducts, ventilation lines

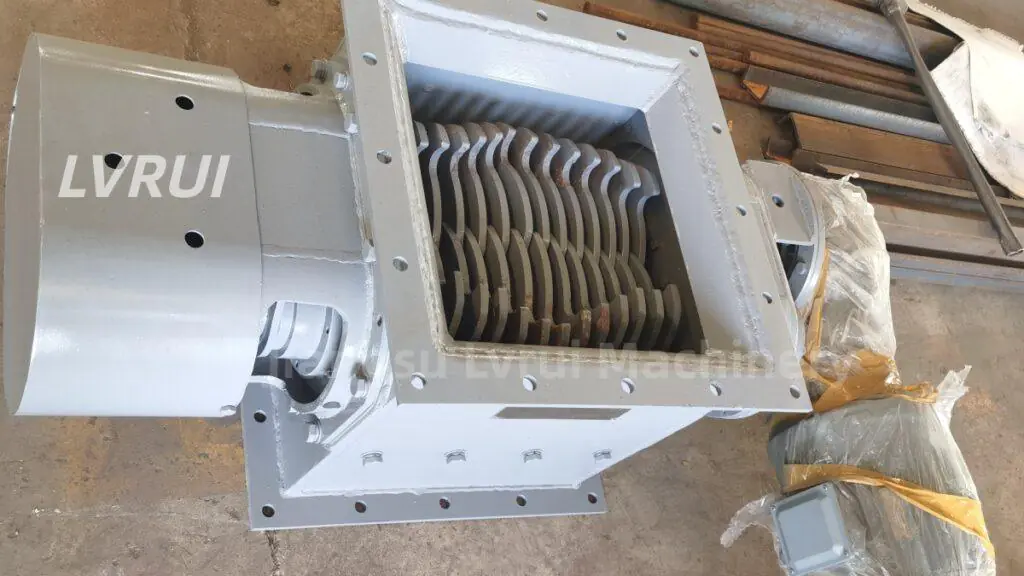

3.2 Louver Damper Valve

Louver damper valves consist of multiple blades that provide more precise airflow regulation.

Advantages:

- Better airflow distribution

- Lower pressure loss compared to single-blade dampers

- Suitable for high-temperature and kiln systems

Common applications:

Kiln systems, preheaters, large airflow balancing points

3.3 Slide Gate & Specialized Dampers (Application-Specific)

For isolation or high sealing requirements, slide-type or specially designed dampers may be integrated into cement airflow systems.

4. Critical Factors to Consider When Selecting a Damper Valve

Critical Factors When Selecting a Damper Valve for Cement Plant Applications

4.1 Operating Temperature

Cement plant airflow temperatures may exceed 300–1000°C in kiln and preheater zones.

Damper valves must be designed with:

- Heat-resistant materials

- Thermal expansion compensation

- Proper shaft and bearing protection

4.2 Dust Load and Abrasiveness

Cement dust is highly abrasive and can cause blade erosion, sealing failure, and material buildup inside duct systems. According to the physical characteristics of cement dust, long-term exposure to fine particulate matter significantly accelerates wear on airflow control components. In dusty environments, damper valves must be designed with reinforced blades, wear-resistant liners, and appropriate clearances to ensure reliable operation.

4.3 Sealing Performance

Different applications require different sealing levels:

- Standard airflow regulation → moderate sealing

- System isolation or process stability → tight shut-off

Choosing the correct sealing structure directly impacts energy efficiency and process safety.

4.4 Pressure Drop and Flow Control Accuracy

Well-designed damper valves minimize pressure loss while maintaining stable airflow regulation—especially important for fan efficiency and kiln balance.

4.5 Actuation Method: Manual vs Motorized

- Manual damper valves: Simple, cost-effective, suitable for fixed or rarely adjusted systems

- Motorized damper valves: Ideal for automated airflow control, DCS integration, and real-time process adjustment

5. Common Damper Valve Selection Mistakes in Cement Plants

- Choosing valves based on diameter only

- Ignoring dust accumulation and wear

- Underestimating operating temperature

- Using low-sealing dampers in isolation applications

Avoiding these mistakes significantly reduces downtime and maintenance costs.

6. How Proper Damper Valve Selection Improves Cement Plant Performance

Correctly selected damper valves help achieve:

- Stable kiln operation

- Reduced fan power consumption

- Improved dust control efficiency

- Longer service life of duct systems

- Lower overall maintenance costs

In large-scale production lines, selecting the appropriate damper valve for cement plant airflow control is essential to maintain stable draft conditions, reduce energy loss, and ensure long-term system reliability.

FAQs – Damper Valve Selection for Cement Plants

Q1: What is the most common damper valve used in cement plants?

Butterfly and louver damper valves are the most commonly used types for cement plant airflow control.

Q2: Can butterfly damper valves handle cement dust?

Yes, when properly designed with wear-resistant blades and suitable clearances.

Q3: Are motorized damper valves necessary in cement plants?

Motorized dampers are recommended for systems requiring automated airflow regulation and precise process control.

Q4: How do I choose between a butterfly damper and a louver damper?

The choice depends on airflow volume, control accuracy, pressure loss requirements, and operating temperature.

Q5: What materials are best for high-temperature damper valves?

Carbon steel, heat-resistant alloy steel, and customized refractory-lined designs are commonly used.

Why Choose LVRUI Damper Valves for Cement Plant Airflow Control

LVRUI specializes in industrial damper valve solutions for cement, mining, and bulk material handling systems, offering:

✔ Engineered designs for high-temperature and dusty environments

✔ Reliable airflow control with optimized sealing performance

✔ Manual and motorized damper valve options

✔ Custom sizes and materials for cement plant applications

📩 Need a Reliable Damper Valve for Your Cement Plant?

LVRUI provides high-performanceLVRUI provides high-performance damper valve for cement plant airflow control systems, designed for high-temperature and dusty industrial environments. Damper Valves designed specifically for cement plant airflow control systems.

Contact our engineering team today to get the right damper valve solution for your application.

Email: info@lvrui-conveyor.com

Website: https://lvrui-conveyor.com

Ringkasan Singkat Bahasa Indonesia

Damper valve merupakan komponen penting dalam sistem pengendalian aliran udara di pabrik semen yang mempengaruhi stabilitas proses, efisiensi energi, dan pengendalian debu. Artikel ini membahas panduan teknis pemilihan damper valve yang tepat untuk aplikasi pabrik semen, termasuk faktor suhu operasi, kondisi debu, kebutuhan sealing, dan metode penggerak. Dengan pemilihan damper valve yang sesuai, sistem aliran udara dapat bekerja lebih stabil dan efisien dalam jangka panjang

📩 Butuh Damper Valve yang andal untuk pabrik semen Anda?

LVRUI menyediakan solusi Damper Valve industri untuk sistem kiln, preheater, dan dust collection.

Email: info@lvrui-conveyor.com

Website: https://lvrui-conveyor.com