English Summary

This complete guide explains how Cement Bulk Loaders work in cement plants, fly ash systems, and bulk powder handling operations. Learn how FCV Gate (Cement Silo) and FCV Gate (Fly Ash Silo) ensure smooth and stable discharge, improve loading efficiency, reduce dust pollution, and enhance overall material handling performance.

Ringkasan Bahasa Indonesia

Panduan lengkap ini menjelaskan cara kerja Cement Bulk Loader dalam pabrik semen, sistem fly ash, dan aplikasi penanganan material bubuk. Pelajari bagaimana FCV Gate (Cement Silo) dan FCV Gate (Fly Ash Silo) membantu menjaga aliran material tetap stabil, meningkatkan efisiensi pemuatan, mengurangi debu, serta meningkatkan kinerja sistem penanganan material secara keseluruhan.

1. What Is a Cement Bulk Loader?

A Cement Bulk Loader is a specialized loading system designed to transfer dry powdered materials—such as cement, fly ash, clinker powder, and lime—into bulk trucks or tankers.

Its main functions include:

- Dust-free material loading

- Accurate loading control

- Stable powder discharge

- Real-time weight monitoring

- Preventing material leakage during loading

Bulk loaders are widely used in cement plants, concrete batching plants, fly ash processing facilities, and material distribution centers.

2. Working Principle of Cement Bulk Loader

The cement bulk loading system typically includes:

- Storage silo

- FCV Gate (Cement Silo) / FCV Gate (Fly Ash Silo)

- Screw conveyor or air slide conveyor

- Loading spout (telescopic chute)

- Dust collection system

- Weighing system

- Pneumatic or electric actuators

▶ Step-by-step Working Process

1. Material Discharge from Silo

The material inside the silo starts flowing through a Flow Control Valve (FCV Gate).

- For cement → FCV Gate (Cement Silo)

- For fly ash → FCV Gate (Fly Ash Silo)

These valves ensure smooth and controlled material discharge.

2. Conveying Material to Loading Point

Material is transported to the bulk loader via:

- Screw conveyors

- Air slide systems

- Pneumatic conveying lines

3. Loading Spout Positioning

The telescopic loading spout lowers into the truck or tanker, forming a sealed loading connection.

4. Dust-Free Loading

Built-in dust collectors remove airborne particles, preventing environmental pollution.

5. Automatic Shutoff

When the material reaches the preset weight:

- The system automatically closes the FCV Gate

- The loading spout retracts

- The loading cycle ends

This ensures precise loading with no waste.

3. Key Components of a Cement Bulk Loader

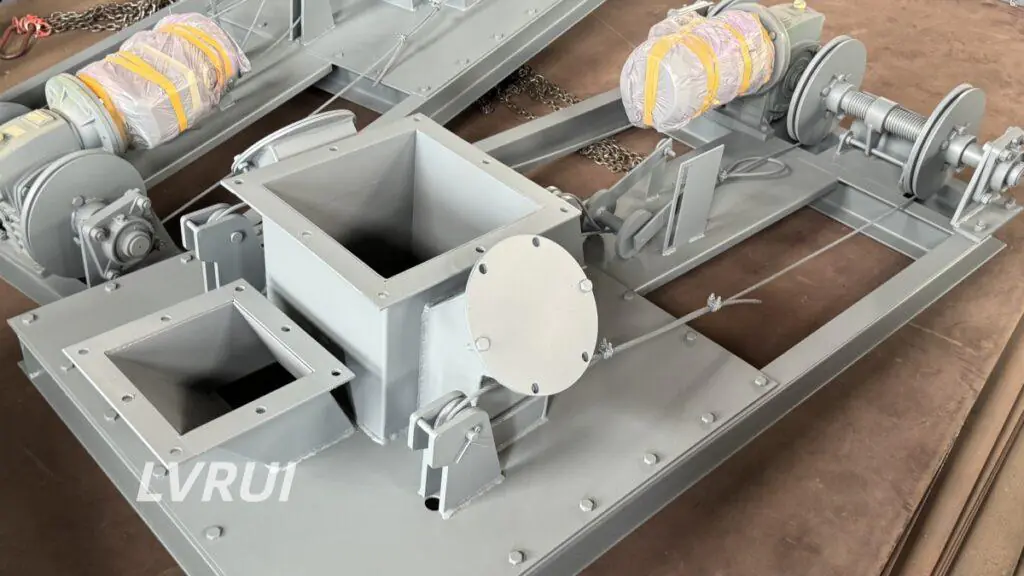

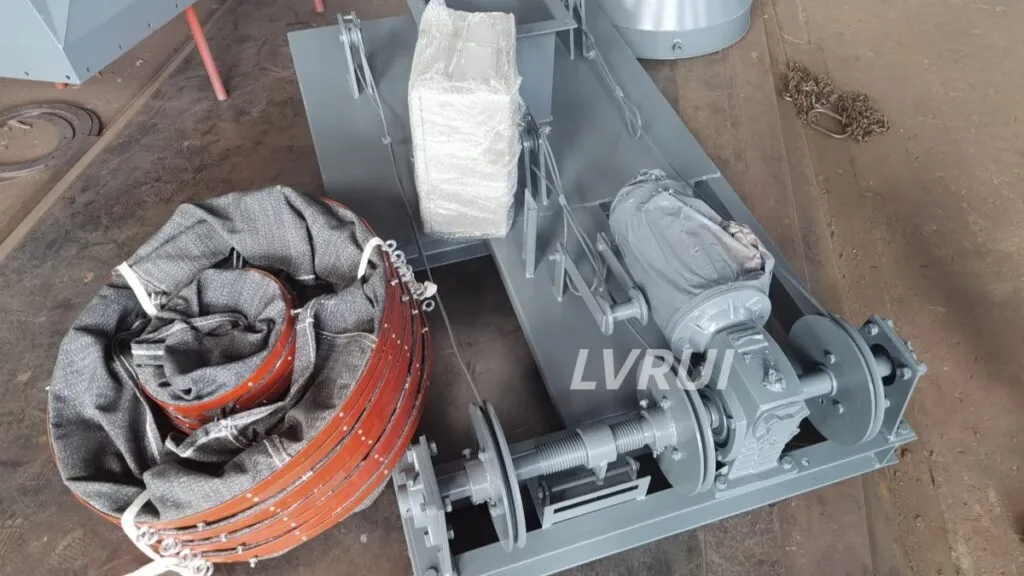

✓ FCV Gate (Cement Silo / Fly Ash Silo)

Controls material discharge from silo and prevents blockage.

✓ Telescopic Loading Spout

Adjustable chute for dust-free material loading into trucks.

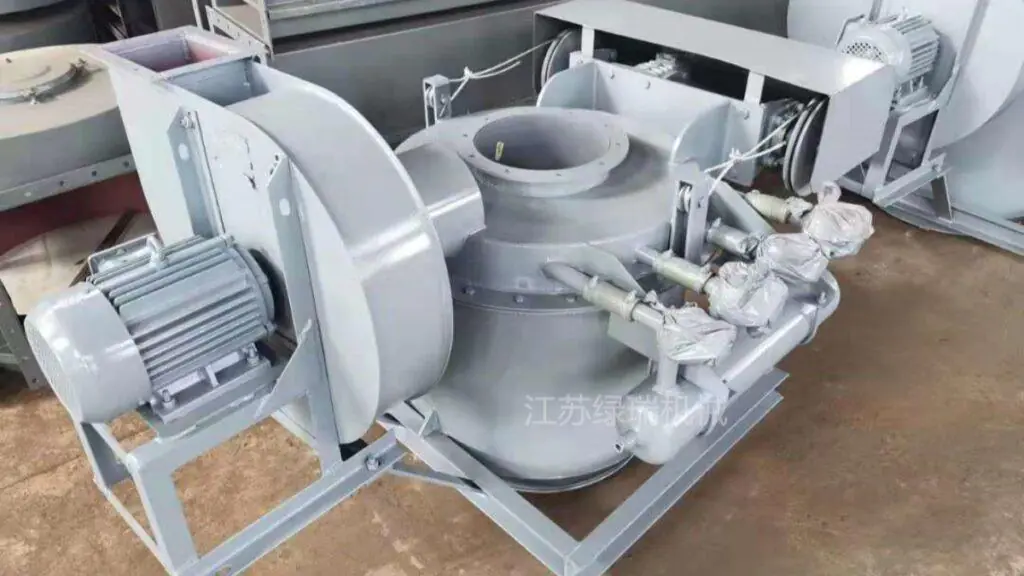

✓ Dust Collector

Ensures clean and environmental-friendly operation.

✓ Weighing System

Ensures loading accuracy and prevents overfilling.

✓ Flow Sensors & Automation System

Provides automatic start/stop and real-time monitoring.

4. Applications of Cement Bulk Loaders

Cement Bulk Loaders are used in:

- Cement plants

- Fly ash processing stations

- Clinker and powder transport centers

- Concrete batching plants

- Dry mix mortar factories

- Bulk distribution terminals

- Mining and mineral industries

They are suitable for loading materials such as:

- Cement powder

- Fly ash

- Clinker powder

- Limestone powder

- Slag powder

- Gypsum

5. Benefits of Using LVRUI Cement Bulk Loader

✓ Fast Loading Efficiency

High throughput significantly reduces truck waiting time.

✓ Dust-Free Operation

Air filters and sealing systems protect your environment.

✓ Stable Material Flow

Works perfectly together with FCV Gate (Cement Silo) and FCV Gate (Fly Ash Silo).

✓ Accurate Loading Control

Automatic weighing ensures precise truck loading.

✓ High Durability

Made with anti-abrasion steel and industrial-grade components.

✓ Easy Integration

Compatible with existing silos, conveyors, and control systems.

6. Why Choose LVRUI Bulk Loader Systems?

✔ Professional Manufacturing – CNC machining, durable steel structure

✔ Custom Design – Cement, fly ash, and powder loading solutions

✔ Export Experience – Indonesia, Vietnam, UAE, Saudi Arabia, Africa

✔ Technical Support – Drawings, installation guidance, after-sales service

7. Indonesian Summary — Ringkasan Bahasa Indonesia

Cement Bulk Loader digunakan untuk memuat semen, fly ash, dan material bubuk lainnya ke dalam truk atau tanker secara cepat dan tanpa debu. Sistem ini bekerja bersama FCV Gate (Cement Silo) dan FCV Gate (Fly Ash Silo) untuk memastikan aliran material stabil dan presisi.

Keuntungan:

- Operasi tanpa debu

- Pengisian cepat

- Kontrol aliran yang stabil

- Pemantauan berat otomatis

- Mengurangi kerugian material

Contact Our Engineering Team

📧 Email: lrst88@126.com

📱 WhatsApp: +86 18261998937

📦 What We Supply

✓ Lump Breaker

✓ Flow Control Valve (FCV)

✓ FCV Gate (Cement Silo)

✓ FCV Gate (Fly Ash Silo)

✓ Rotary Valve

✓ Air Slide Conveyor

✓ Bucket Elevator

✓ Dust Collector

✓ Complete Bulk Material Handling Systems

🌍 Exported to 30+ Countries

Indonesia · Vietnam · Saudi Arabia · UAE · Bangladesh · Africa · South America