(EN)High-Efficiency Multi-Louver Damper Valve for Stable Airflow & Tight Shutoff

(ID) Katup Damper Louver Multi Efisiensi Tinggi untuk Aliran Udara Stabil & Penutupan Rapat

Introduction

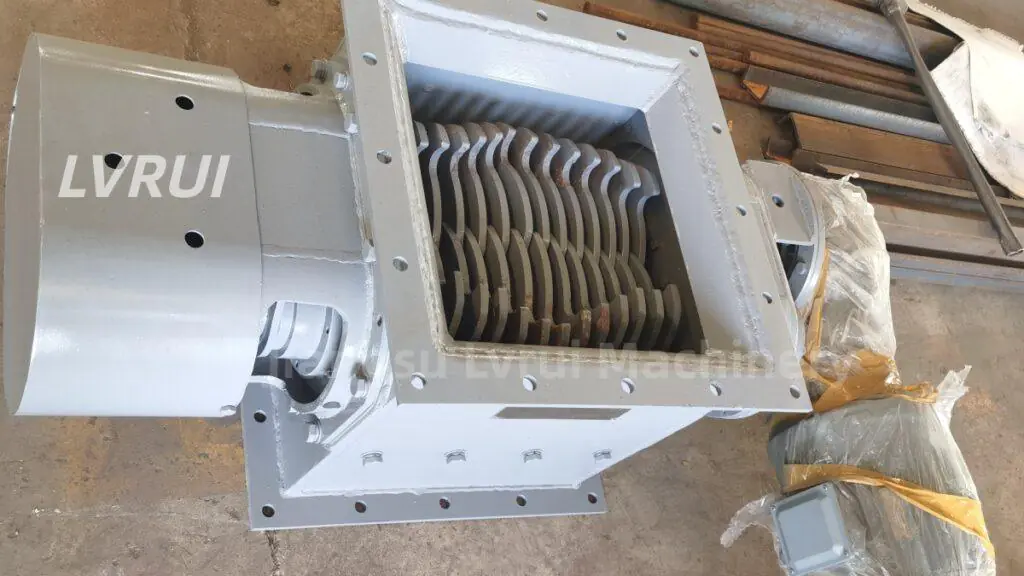

A Louver Damper Valve—also known globally as Multi-Louver Damper, Industrial Louver Damper, Louver Isolation Damper, Airflow Control Louver, Duct Louver Damper, Parallel-Blade Damper, Opposed-Blade Damper—is a key component in large industrial ducting systems.

It provides precise airflow modulation, tight shutoff, and low-leakage control for industries such as cement, power generation, steel, metallurgy, petrochemical, and mining.

Designed for high temperature and high dust environments, Louver Dampers are widely used in:

- ID Fan / FD Fan ducts

- Rotary kiln and clinker cooler ducts

- SCR / FGD / ESP systems

- Hot gas ducts and bypass lines

- Industrial ventilation systems

For more airflow and bulk material solutions, you can also explore LVRUI’s full product range here → https://lvrui-conveyor.com/

What Is a Louver Damper Valve?

A Louver Damper Valve consists of multiple parallel or opposed blades, operating simultaneously to control gas volume.

Compared with butterfly dampers, louver systems offer:

- Better airflow distribution

- Lower pressure loss

- Higher sealing efficiency

- Lower operating torque on large ducts

- More stable modulation control

This makes it the preferred damper for medium to ultra-large duct sizes.

To better understand how damper systems work in industrial airflow control, you may refer to the engineering principles described here:

Wikipedia – Damper (flow)

https://en.wikipedia.org/wiki/Damper_(flow)

Key Features of LVRUI Louver Damper Valve

✔ Low-Leakage Sealing Design

Soft + hard sealing structures allow leakage levels of ≤2–3%, and with seal-air system, leakage can be reduced to ≤0.5%.

✔ High-Temperature Resistant

Material options include carbon steel, stainless steel (304/316), heat-resistant steel, suitable for 700–900°C.

✔ Airfoil Blade Shape

Reduces turbulence, improves airflow stability, and optimizes energy efficiency.

✔ Flexible Actuation Options

Electric, pneumatic, or hydraulic actuators with manual override.

✔ Compatible with DCS / PLC Systems

4–20 mA feedback, switches, Modbus, and other control options.

✔ Customizable Shapes & Sizes

Round, square, rectangular, or non-standard geometry available per project design.

Applications of Louver Damper Valve

Louver dampers are used in many industrial gas systems:

- Modulating control of fan airflow

- Isolation when combined with Guillotine Damper

- Bypass switching in SCR / FGD systems

- Kiln bypass and hot air furnace lines

- Clinker cooler exhaust regulation

Whether for airflow balancing or tight shutoff, Louver Dampers ensure reliability and high performance.

Industry engineers commonly follow standardized airflow and material-handling guidelines such as those published by:

CEMA – Bulk Material Handling Standards

https://www.cemanet.org/

📞 Contact LVRUI for a Custom Louver Damper Valve Solution

LVRUI provides professional louver damper valves, multi-louver dampers, isolation dampers, airflow control dampers, and high-temperature duct valves for cement plants, power plants, steel mills, mining industries, and industrial gas-handling systems.

Our engineering team offers custom design, actuator selection, seal-air options, and complete airflow solutions tailored to your project requirements.

📩 Email: lrslt88@126.com

🌐 Website: https://lvrui-conveyor.com/

💬 Contact us for a free quotation and professional technical support anytime.

Versi Singkat dalam Bahasa Indonesia (Untuk Pasar Indonesia)

Ringkasan Produk: Louver Damper Valve

Louver Damper Valve adalah katup pengatur aliran udara industri yang menggunakan beberapa bilah (multi-louver) untuk mengontrol volume gas secara presisi. Katup ini banyak digunakan pada pabrik semen, pembangkit listrik, pabrik baja, sistem kiln, dan ducting suhu tinggi.

Keunggulan Utama

- Kebocoran Rendah (Low Leakage) dengan opsi seal-air untuk kinerja isolasi yang lebih baik

- Tahan Suhu Tinggi hingga 700–900°C (tergantung material)

- Bilah airfoil yang mengurangi turbulensi udara

- Tersedia aktuator electric, pneumatic, atau hydraulic

- Cocok untuk duct bulat, persegi, atau rectangular

- Desain dapat dikustomisasi sesuai kebutuhan proyek

Aplikasi Umum

- Pengaturan aliran pada ID/FD fan duct

- Sistem Rotary Kiln & Clinker Cooler

- SCR/FGD/ESP bypass pada pembangkit listrik

- Sistem ventilasi & ducting industri

Mengapa Memilih LVRUI?

LVRUI memiliki pengalaman dalam memproduksi multi-louver damper valve, isolation damper, high-temperature duct valves, serta menyediakan solusi rekayasa lengkap untuk kebutuhan pabrik semen dan industri berat.

Kami mendukung proyek-proyek di Indonesia dengan kualitas terjamin, harga kompetitif, dan pengiriman cepat.

📞 Hubungi LVRUI untuk Solusi Louver Damper Valve

Jika Anda membutuhkan louver damper valve untuk ducting industri atau sistem kiln bersuhu tinggi,

silakan hubungi LVRUI untuk konsultasi teknik dan penawaran resmi.

📩 Email: info@lvrui-conveyor.com

🌐 Website: https://lvrui-conveyor.com/

💬 LVRUI siap membantu kebutuhan teknis Anda kapan saja.