Selecting a Motorized Flow Control Gate Valve is a critical step in ensuring smooth, efficient, and safe material flow in bulk handling systems. The right valve helps prevent material blockage, supports accurate dosing, and enhances the automation level of your production line.

In this guide, we’ll look at key selection factors, common application scenarios, and additional considerations to help you choose the best Motorized Flow Control Valve for your facility.

1. Understand Your Material Characteristics

Before choosing the valve, analyze the type of material being handled:

✔ Powder or fine material

✔ Granular material

✔ Cement, clinker, fly ash

✔ Limestone, gypsum, coal, sand

Material behavior directly affects which valve structure and actuator you need.

For general material flow science, you can refer to:

🔗 External Link: https://en.wikipedia.org/wiki/Bulk_material

2. Determine Your Required Flow Control Accuracy

Flow accuracy depends on the actuator and blade design.

Consider whether your process requires:

- Fully open / fully closed operation

- Variable flow control

- Frequency of adjustments

Motorized actuators offer stable and repeatable positioning, especially important for high-precision dosing lines.

For reference on industrial safety and mechanical operation standards:

🔗 OSHA Standard(External Link): https://www.osha.gov/machine-guarding

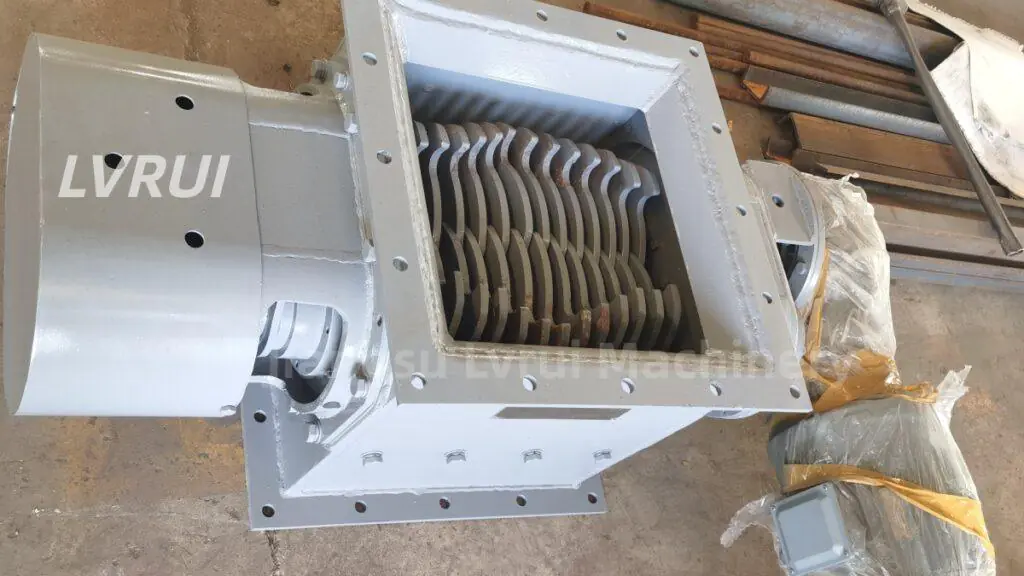

3. Select Valve Construction According to Working Conditions

Evaluate your system environment:

- High temperature?

- Heavy dust?

- Large load cycles?

- Abrasive material?

Heavy-duty welded steel structures perform best in cement plants and mining.

For conveying system guidelines, refer to CEMA:

🔗 CEMA(External Link): https://www.cemanet.org/

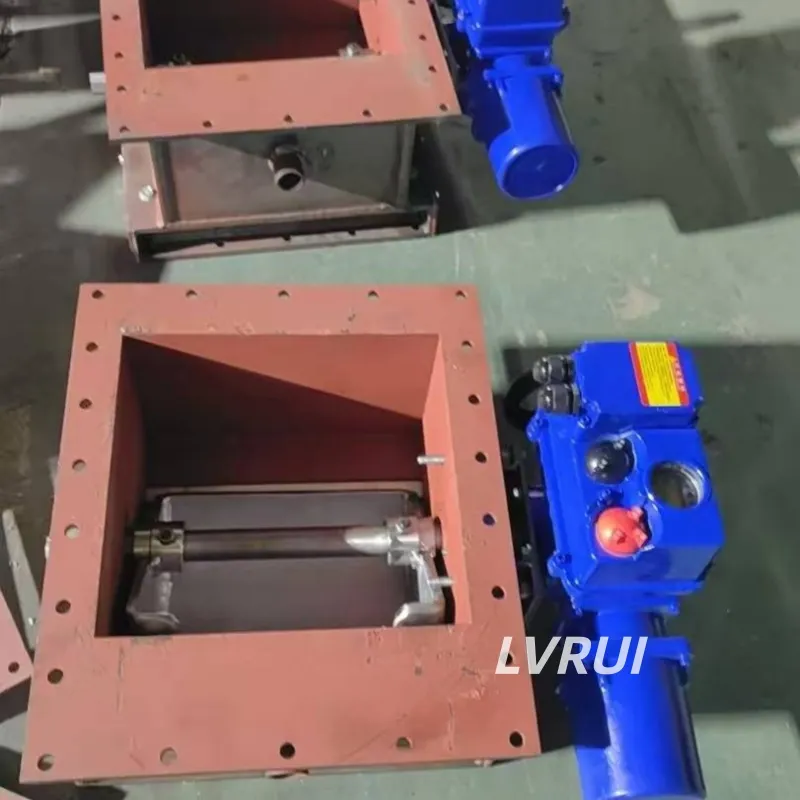

4. Choose the Right Actuator Type

Motorized Flow Control Valves typically use:

🔘 Electric Actuator

- Stable positioning

- Automation compatibility

- Smooth operation

- Ideal for PLC-controlled production lines

Make sure to check:

✔ Torque output

✔ Opening/closing speed

✔ Voltage requirement

✔ Duty cycle rating

5. Check Installation Size and System Compatibility

Ensure the valve’s:

- Flange size

- Connection method

- Blade stroke

- Installation space

match your screw conveyor, chute, silo, hopper, or pneumatic line.

Internal reference pages you may add to cross-link related products:

🔗 Flow Control Gate: https://lvrui-conveyor.com/flow control gate valve (You can replace with your actual Flow Control Gate page)

🔗 Diverter Valve: https://lvrui-conveyor.com/ (choose actual diverter valve URL)

🔗 Butterfly Damper Valve: https://lvrui-conveyor.com/butterfly-damper-valve/

Internal linking helps SEO ranking and keeps customers browsing longer.

6. Consider Maintenance, Spare Parts, and Reliability

A good valve should have:

✔ Replaceable sealing components

✔ Durable bearings

✔ Corrosion-resistant coating

✔ Easy-to-maintain structure

Choosing a reliable manufacturer ensures better spare parts availability and long-term stability.

Conclusion

Choosing the right Motorized Flow Control Gate Valve requires an understanding of your material, flow requirements, working environment, and automation system. Working with an experienced supplier like LVRUI ensures you receive the right equipment and technical support for long-term stable operation.

Standard CTA

Looking for a reliable Motorized Flow Control Gate Valve for your project?

LVRUI provides professional design, durable construction, and customized automation solutions.

👉 Contact Us Today:

Email: info@lvrui-conveyor.com

Website: https://lvrui-conveyor.com

WeChat / WhatsApp: +86 18261998937

Indonesian Short Version

Cara Memilih Motorized Flow Control Gate Valve yang Tepat

Memilih Motorized Flow Control Gate Valve yang sesuai sangat penting untuk memastikan aliran material yang stabil dan efisiensi sistem material handling.

Hal yang perlu diperhatikan:

✔ Jenis & karakter material

✔ Tingkat presisi kontrol aliran

✔ Kondisi kerja seperti debu & suhu

✔ Jenis aktuator dan torsi

✔ Ukuran pemasangan & kompatibilitas sistem

Valve yang tepat akan meningkatkan keandalan, mengurangi downtime, dan mendukung otomatisasi proses industri Anda.