(EN) A Practical Guide to Selecting Rod Gates for Reliable Bulk Material Flow Control

(ID) Panduan Praktis Memilih Rod Gate untuk Pengendalian Aliran Material Curah yang Andal

Introduction

Selecting the right rod gate is critical for ensuring stable flow control, reliable sealing, and long-term performance in bulk material handling systems.

Rod gates are widely used in cement plants, fly ash handling lines, powder silos, and gravity discharge systems where controlled material isolation is required.

In this article, we will explain how a rod gate works, what factors affect its performance, and how to select the correct design for your bulk material application.

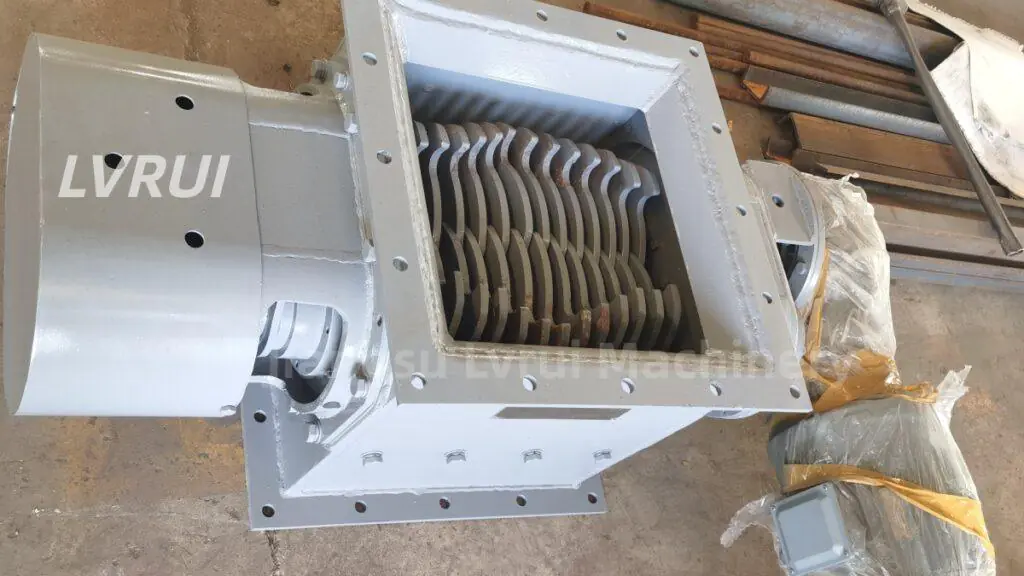

What Is a Rod Gate?

A rod gate is a mechanical flow isolation device designed to control or shut off bulk materials such as cement, fly ash, clinker, limestone powder, and other granular materials.

Unlike knife gates or slide gates, rod gates use parallel rods to form an adjustable opening, allowing material to pass while preventing blockage and arching.

Key Characteristics of Rod Gates:

- Open-frame structure with multiple parallel rods

- Excellent anti-blocking performance

- Suitable for gravity discharge applications

- Simple mechanical design with low maintenance

How a Rod Gate Works

A rod gate operates by adjusting the spacing between rods to regulate material flow. When the gate is closed, the rods align closely to block material discharge. When opened, controlled gaps allow material to flow evenly.

This design reduces:

- Material bridging

- Powder compaction

- Sudden discharge surges

You can compare rod gates with other flow control devices such as the Flow Control Gate.

Key Factors to Consider When Selecting a Rod Gate

1. Material Characteristics

Different bulk materials behave differently. Before selecting a rod gate, consider:

- Particle size distribution

- Flowability

- Abrasiveness

- Moisture content

Rod gates perform best with:

- Cement

- Fly ash

- Clinker fines

- Limestone powder

2. Application Location

Rod gates are commonly installed:

- Under silos and hoppers

- At chute discharge points

- In gravity-fed conveying systems

For pneumatic conveying applications, consider combining rod gates with an Air Slide Conveyor .

3. Sealing & Leakage Requirements

While rod gates are not designed for airtight sealing like diverter valves, proper rod spacing and surface finish can significantly reduce leakage.

If zero leakage is required, consider:

- Adding secondary sealing

- Using rod gates as pre-isolation devices

- Pairing with downstream diverter valves

See also: Diverter Valve Solutions .

4. Wear Resistance & Material Build Quality

For abrasive materials such as clinker or fly ash:

- Choose wear-resistant steel rods

- Consider hardened or coated surfaces

- Ensure robust frame construction

High-quality rod gates extend service life and reduce maintenance frequency.

5. Actuation & Control

Rod gates can be:

- Manually operated

- Pneumatically actuated

- Motorized for automation systems

For automated bulk material handling lines, motorized rod gates allow integration with PLC and plant control systems.

For general bulk material flow behavior, refer to https://en.wikipedia.org/wiki/Bulk_material_handling

Rod Gate vs Other Bulk Material Gates

| Device Type | Best Use Case |

|---|---|

| Rod Gate | Anti-blocking gravity discharge |

| Slide Gate | Precise flow isolation |

| Knife Gate | Tight shut-off with sealing |

| Diverter Valve | Flow direction control |

Rod gates are especially suitable where material flow consistency and clog prevention are more important than airtight sealing.

Typical Applications of Rod Gates

Rod gates are widely used in:

- Cement plants

- Fly ash handling systems

- Bulk powder silos

- Hopper discharge outlets

- Gravity-fed conveying lines

They are often combined with telescopic loading chutes and air slide conveyors in modern bulk material handling systems.

Why Choose LVRUI Rod Gate Solutions?

LVRUI rod gates are engineered for:

- Reliable flow control

- Durable industrial construction

- Custom sizing and materials

- Seamless integration into bulk handling systems

✔ Custom design for cement & powder applications

✔ Strong anti-blocking performance

✔ Long service life with minimal maintenance

Conclusion

Choosing the right rod gate depends on material characteristics, discharge conditions, wear resistance, and system integration requirements.

When properly selected, a rod gate improves flow reliability, reduces downtime, and enhances overall bulk material handling efficiency.

Need a reliable Rod Gate for your bulk material handling system?

LVRUI provides custom-engineered rod gates for cement, fly ash, and powder conveying applications.

📩 Email: info@lvrui-conveyor.com

🌐 Website: https://lvrui-conveyor.com

Versi Singkat (Bahasa Indonesia)

Rod gate adalah perangkat penting dalam sistem penanganan material curah seperti semen, fly ash, dan bubuk industri lainnya. Desain batang paralel pada rod gate membantu mencegah penyumbatan dan memastikan aliran material yang stabil.

Dalam memilih rod gate yang tepat, faktor utama yang perlu dipertimbangkan meliputi jenis material, lokasi pemasangan, ketahanan aus, serta metode pengoperasian (manual atau otomatis). Rod gate sangat cocok digunakan pada sistem pengeluaran gravitasi di silo, hopper, dan jalur conveying.

Rod gate dari LVRUI dirancang untuk aplikasi industri berat dengan struktur kuat, performa andal, dan umur pakai yang panjang.